ASME SA-106/SA-106M-2015 Carbon karfe bututu

| Daidaito:ASTM SA106 | Alloy Ko A'a: A'a |

| Rukuni mai daraja: GR.A, GR.B, GR.C da dai sauransu | Aikace-aikace: Fluid Pipe |

| Kauri: 1-100 mm | Surface Jiyya: A matsayin abokin ciniki ta bukata |

| Diamita na waje (Zagaye): 10 - 1000 mm | Fasaha: Hot Rolled |

| Tsawon: Kafaffen tsayi ko tsayin bazuwar | Maganin zafi: Annealing / normalizing |

| Siffar Sashe: Zagaye | Bututu na Musamman: Babban zafin jiki |

| Wurin Asalin: China | Amfani: Gina, Jirgin Ruwa |

| Takaddun shaida: ISO9001:2008 | Gwaji: ECT/CNV/NDT |

Bututun ƙarfe mara ƙarfi don aiki mai zafiASTM A106, dace da high zafin jiki, Ana amfani da ko'ina a cikin man fetur, sinadaran masana'antu, tukunyar jirgi, tashar wutar lantarki, jirgin ruwa, inji masana'antu, mota, jirgin sama, Aerospace, makamashi, geology, yi da soja masana'antu da sauran masana'antu.

Matsayi na babban ingancin tsarin ƙarfe na carbon: GR.A, GR.B, GR.C

| Rubutu, ( | |||

| Darasi A | Darasi B | Darasi C | |

| Carbon, max | 0.25A | 0.3B | 0.35B |

| Manganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus, max | 0.035 | 0.035 | 0.035 |

| Sulfur, max | 0.035 | 0.035 | 0.035 |

| Silikon, min | 0.10 | 0.10 | 0.10 |

| Chrome, maxC | 0.40 | 0.40 | 0.40 |

| Copper, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| A Ga kowane raguwa na 0.01% ƙasa da ƙayyadaddun iyakar carbon, haɓakar 0.06% manganese sama da iyakar ƙayyadaddun za a ba da izini har zuwa matsakaicin 1.35%. | |||

| B Sai dai in ba haka ba wanda mai siye ya ayyana, ga kowane raguwar 0.01% ƙasa da ƙayyadaddun iyakar carbon, za a ba da izinin haɓaka 0.06% manganese sama da iyakar ƙayyadaddun har zuwa matsakaicin 1.65%. | |||

| C Wadannan abubuwa biyar da aka haɗe ba za su wuce 1% ba. | |||

| Darasi A | Darasi B | Darasi C | ||||||

| Ƙarfin ɗamara, min, psi(MPa) | 48000 (330) | 60000 (415) | 70000 (485) | |||||

| Ƙarfin Haɓaka, min, psi(MPa) | 30000 (205) | 35000 (240) | 40000 (275) | |||||

| Tsayi | Canza | Tsayi | Canza | Tsayi | Canza | |||

| Tsawaita cikin inci 2 (50 mm), min, % Mahimmin ƙarancin gwajin tsiri mai tsayi na elongation, kuma ga duk ƙananan girman da aka gwada a cikin cikakken sashe | 35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| Lokacin daidaitaccen zagaye 2-in. (50-mm) ana amfani da samfurin gwajin tsayin ma'auni | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Don gwajin tsiri mai tsayi | A | A | A | |||||

| Don gwaje-gwajen tsiri mai jujjuyawa, ragi ga kowane 1/32-in. (0.8-mm) raguwa a kaurin bangon da ke ƙasa da 5/16 in. (7.9 mm) daga ƙaramin ƙaramar ƙaranci na kashi mai zuwa za a yi. | 1.25 | 1.00 | 1.00 | |||||

| A mafi ƙarancin elongation a cikin inci 2. (50 mm) za a ƙayyade ta ma'auni mai zuwa: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| don raka'a-laba, da | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| don raka'a SI, | ||||||||

| inda: e = ƙaramar haɓakawa a cikin 2 in. (50 mm), %, zagaye zuwa mafi kusa 0.5%, A = yankin giciye na samfurin gwajin tashin hankali, a cikin.2 (mm2), dangane da ƙayyadaddun diamita na waje ko ƙayyadaddun ƙayyadaddun diamita na waje ko faɗin ƙirar ƙira da ƙayyadadden kauri na bango, zagaye zuwa mafi kusa 0.01 in.2 (1 mm2). (Idan yankin da aka lissafta haka yana daidai da ko mafi girma fiye da 0.75 in.2 (500 mm2), to za a yi amfani da ƙimar 0.75 in.2 (500 mm2). U = ƙayyadadden ƙarfin ƙarfi, psi (MPa). | ||||||||

Baya ga tabbatar da abun da ke tattare da sinadarai da kaddarorin injina, ana yin gwaje-gwajen hydrostatic daya bayan daya, kuma ana yin gwaje-gwajen flaring da flattening. . Bugu da ƙari, akwai wasu buƙatu don ƙananan ƙwayoyin cuta, girman hatsi, da decarburization Layer na bututun ƙarfe da aka gama.

Ikon samarwa: Ton 1000 a kowane wata kowane Grade na ASTM SA-106 Bututu Karfe

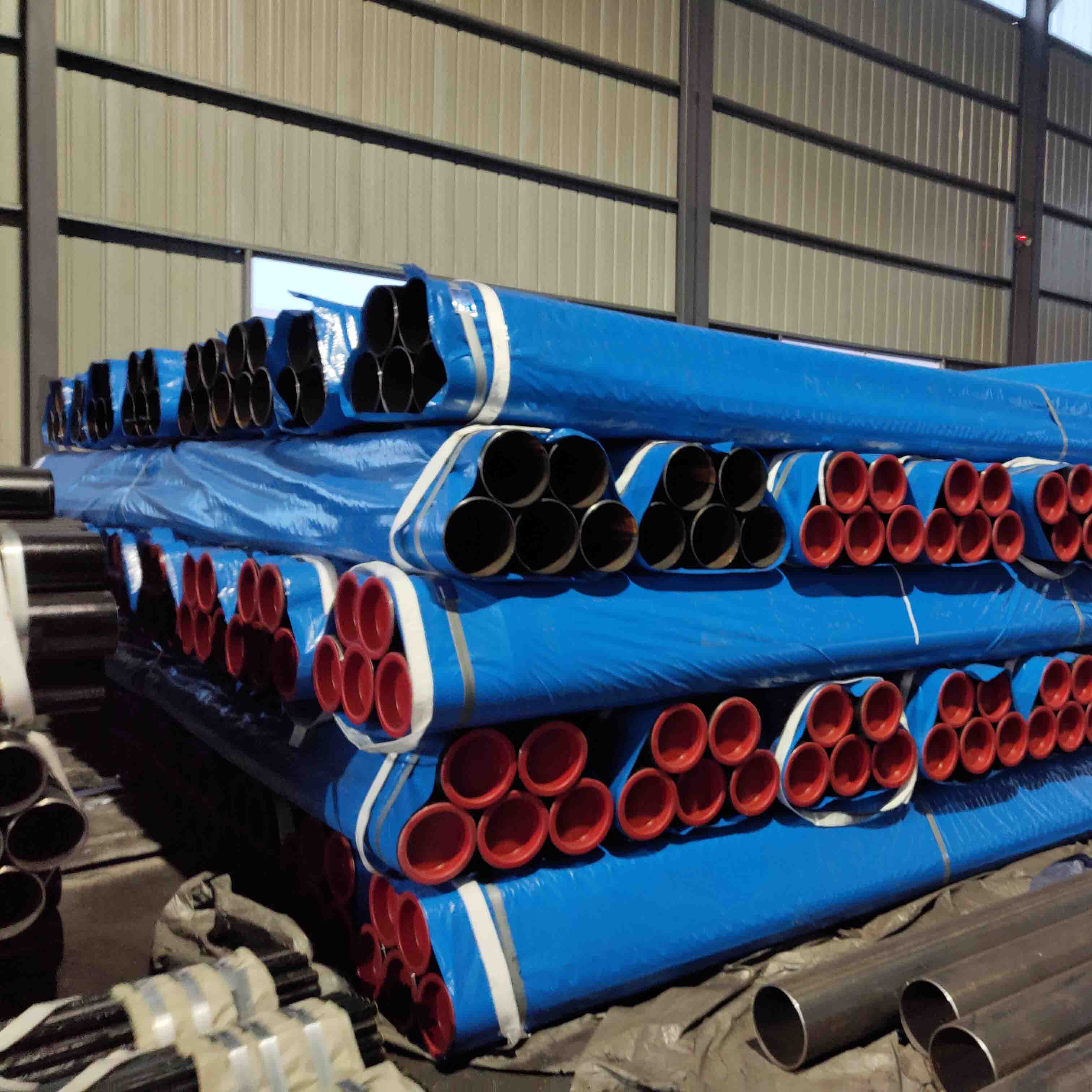

A cikin daure da A cikin Akwatin katako mai ƙarfi

7-14 kwanaki idan a stock, 30-45 kwanaki don samar

30% depsoit, 70% L/C ko B/L kwafin ko 100% L/C a gani