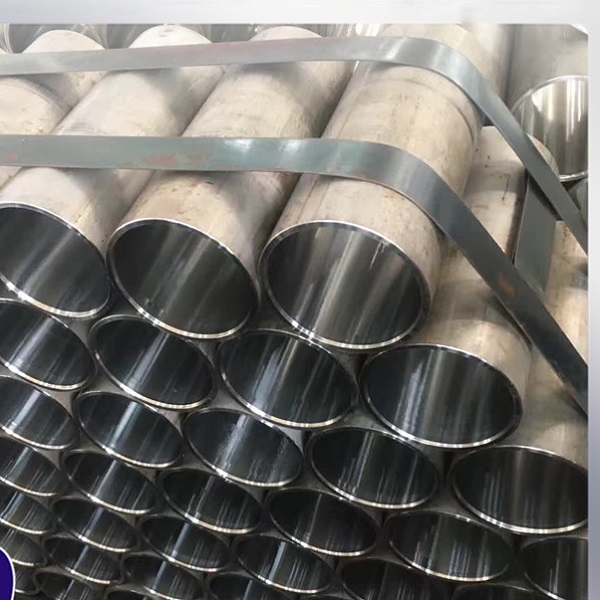

[Kwafi] Bututun Karfe Na Karfe Don Fashewar Man Fetur, GB9948-2006, Sanon Pipe

Dubawa

Misali: GB9948-2006

Rukuni mai daraja: 10,12CrMo,15CrMo, 07Crl9Nil0, da dai sauransu

Kauri: 1-100 mm

Diamita na waje (Zagaye): 10 - 1000 mm

Tsawon: Kafaffen tsayi ko tsayin bazuwar

Siffar Sashe: Zagaye

Wurin Asalin: China

Takaddun shaida: ISO9001:2008

Maganin zafi: Annealing / normalizing / Tempering

Diamita na waje (Zagaye): 10 - 1000 mm

Aikace-aikacen: bututun musayar zafi

Jiyya na saman: Kamar yadda Buƙatun Abokin ciniki

Fasaha: Hot Rolled

Bututu na Musamman: Bututun bango mai kauri

Amfani: bututun musayar zafi

Gwajin: UT/MT

Aikace-aikace

Bututun ƙarfe mara ƙarfi don fashewar mai suna aiki da bututun ƙarfe maras kyau don bututun murhu, bututun musayar zafi da bututun matsa lamba a masana'antar petrochemical.

High quality carbon tsarin karfe maki ne 20g, 20mng da 25mng.

Alloy tsarin karfe maki: 15mog, 20mog, 12 crmog

15CrMoG, 12Cr2MoG, 12CrMoVG, da dai sauransu

Babban Daraja

Matsayin ƙarfe mai inganci mai inganci: 10#,20#

High quality carbon tsarin karfe maki: 20g, 20mng da 25mng

Alloy tsarin karfe maki: 15mog, 20mog, 12CRmog, 15CrMoG, 12Cr2MoG, da dai sauransu

Abubuwan Sinadari

| No | Daraja | Sinadarin % | ||||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | |||

| ≤ | ||||||||||||||

| High ingancin carbon tsarin karfe | 10 | 0.07-0.13 | 0.17-0. 37 | 0.35-0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0.025 | 0. 015 | |

| 20 | 0.17-0. 23 | 0.17-0. 37 | 0.35-0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0.025 | 0. 015 | ||

| Alloy tsarin karfe | 12CrMo | 0.08-0.15 | 0.17-0.37 | 0.40-0. 70 | 0.40-0. 70 | 0. 40 - 0.55 | <0. 30 | - | - | 一 | <0. 20 | 0.025 | 0. 015 | |

| 15CrMo | 0.12-0.18 | 0.17-0. 37 | 0.40 - 0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0.025 | 0. 015 | ||

| 12CrlMo | 0.08-0.15 | 0.50-1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45-0.65 | <0. 30 | - | - | - | <0, 20 | 0.025 | 0. 015 | ||

| 12CrlMoV | 0.08-0.15 | 0.17-0. 37 | 0.40-0. 70 | 0.90-1.2 | 0.25-0.35 | <0. 30 | - | - | 0.15-0. 30 | <0. 20 | 0.025 | 0. 010 | ||

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0.40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0.025 | 0. 015 | ||

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0.45-0. 60 | <0. 60 | - | - | <0. 20 | 0.025 | 0. 015 | |||

| 12Cr5MoNT | ||||||||||||||

| 12Cr9MoI | <0.15 | 0. 25-1. 00 | 0.30-0. 60 | 8.00 - 10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0.025 | 0, 015 | ||

| 12Cr9MoNT | ||||||||||||||

| Bakin karfe mai jure zafi | 07Crl9Nil0 | 0.04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0.030 | 0. 015 | |

| 07Crl8NillNb | 0.04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0.030 | 0. 015 | ||

| 07Crl9NillTi | 0.04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00-13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0. 015 | ||

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10.00-14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | ||

Kayan Injiniya

| A'a | Tashin hankali MPa | yawa MPa | Tsawon bayan karaya A/% | Ƙarfin shayarwar girgiza kv2/j | Lambar taurin Brinell | ||

| hoto | transver | hoto | transver | ||||

| ba kasa da | ba fiye da | ||||||

| 10 | 335 ~ 475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410-550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410 ~ 560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440 ~ 640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415 ~ 560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470 ~ 640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450-600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415-590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoNT | 480 ~ 640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460 ~ 640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9MoNT | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9NilO | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | >520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | >520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | >485 | 170 | 35 | 一 | - | 187 HBW | |

| Don karfe tare da kaurin bango ƙasa da bututun 5mm kar a yi gwajin taurin | |||||||

Bukatar Gwaji

Gwajin hydraulic

Za a yi gwajin hydraulic don bututun ƙarfe ɗaya bayan ɗaya. Matsakaicin gwajin gwajin shine 20 MPa. A ƙarƙashin gwajin gwajin, lokacin tabbatarwa ba zai zama ƙasa da 10 s ba, kuma ba a yarda da zubar da bututun ƙarfe ba.

Gwajin lallashi

Za a gudanar da gwajin ƙwanƙwasa don bututun ƙarfe tare da diamita na waje fiye da 22 mm

Gwajin walƙiya

High quality carbon tsarin karfe da bakin (zafi-resistant) karfe bututu tare da waje diamita ba fiye da 76 mm da wani bango kauri da ba fiye da 8 mm za su kasance batun faɗaɗa gwaji. Za a gudanar da gwajin walƙiya a cikin ɗaki. A m diamita flaring kudi na samfurin bayan saman core taper ne 60% na flaring zai hadu da bukatun da tebur 7. Babu fasa ko fasa da aka yarda a kan samfurin bayan flaring. Dangane da buƙatun mai buƙata kuma an lura da su a cikin kwangilar, ana iya amfani da ƙirar ƙirar ƙarfe don faɗaɗa gwaji.

Gwajin mara lalacewa

The karfe bututu za su kasance ƙarƙashin ultrasonic flaw ganewa daya bayan daya daidai da tanadi na GB / T 5777-2008. Dangane da bukatun mai buƙata, ana iya ƙara wasu gwaje-gwaje marasa lalacewa bayan tattaunawa tsakanin mai siyarwa da mai buƙata kuma an nuna su a cikin kwangilar.

Gwajin lalatawar intergranular

Za a gudanar da gwajin lalatawar intergranular don bututun ƙarfe (mai jure zafi). Hanyar gwajin za ta kasance daidai da tanadin hanyar Sinanci E a cikin GB / T 4334-2008, kuma ba a ba da izinin lalata halayen intergranular bayan gwajin ba.

Bayan tattaunawa tsakanin mai kaya da mai nema, kuma an lura a cikin kwangilar, mai nema zai iya tsara wasu hanyoyin gwajin lalata.

![[Kwafi] Bututun Karfe Marasa Sumul Don Fashewar Man Fetur, GB9948-2006, Hoton Sanon Bututun Featured](http://www.sanonpipe.com/uploads/ff652257.jpg)

![[Kwafi] Bututun Karfe Na Karfe Don Fashewar Man Fetur, GB9948-2006, Sanon Pipe](http://www.sanonpipe.com/uploads/ff652257-300x300.jpg)

![[Kwafi] Bututun Karfe Na Karfe Don Fashewar Man Fetur, GB9948-2006, Sanon Pipe](http://www.sanonpipe.com/uploads/8f454869-300x300.jpg)

![[Kwafi] Bututun Karfe Na Karfe Don Fashewar Man Fetur, GB9948-2006, Sanon Pipe](http://www.sanonpipe.com/uploads/e19d0a6e-300x300.jpg)