Samfurin kyauta don China ASTM A53/BS1387 Zare da Haɗaɗɗen Bututun Karfe mai zafi

Dubawa

Kowane memba daga manyan ma'aikatan kuɗin shiga namu yana kimanta bukatun abokan ciniki da sadarwar ƙungiyar don ASTM A53/BS1387 Hot Dipped Galvanized Steel Pipe. Tare da mu kuɗin ku cikin aminci kasuwancin ku cikin aminci. Da fatan za mu iya zama amintaccen mai samar da kayayyaki a kasar Sin. Neman haɗin gwiwar ku .Tare da fiye da shekaru 9 na gwaninta da ƙungiyar ƙwararru, mun fitar da samfuranmu zuwa ƙasashe da yankuna da yawa a duk faɗin duniya. Muna maraba da abokan ciniki, ƙungiyoyin kasuwanci da abokai daga duk sassan duniya don tuntuɓar mu da neman haɗin kai don fa'idodin juna.

Hot-tsoma galvanizing yana da abũbuwan amfãni daga uniform shafi, karfi mannewa da kuma dogon sabis rayuwa. Rikicin halayen jiki da na sinadarai suna faruwa tsakanin matrix bututun ƙarfe da narkakken plating bayani don samar da lallausan gami da tutiya-baƙin ƙarfe mai jure lalata tare da ɗan ƙaramin tsari. An haɗa Layer alloy tare da tsantsar zinc Layer da matrix na bututun ƙarfe. Saboda haka, juriya na lalata yana da ƙarfi.

Ya kamata a lura cewa a shekarun 1960 da 1970, kasashe da suka ci gaba a duniya sun fara samar da sabbin nau'ikan bututu kuma a hankali an dakatar da bututun galvanized. Ma'aikatu da kwamitoci 4 da suka hada da ma'aikatar gine-gine ta kasar Sin su ma sun fitar da wata takarda da ke fayyace cewa an hana fasa bututun mai daga shekarar 2000 zuwa gaba. Ba kasafai ake amfani da bututun ruwa mai sanyi ba a cikin sabbin al'ummomin da aka gina, kuma ana amfani da bututun da aka yi amfani da su wajen bututun ruwan zafi a wasu al'ummomi.

Aikace-aikace

Ana amfani da shi ne musamman don ƙarfi da sassa na matsa lamba, kuma don maƙasudin tururi, ruwa, iskar gas da bututun iska.

Babban Daraja

GR.A, GR.B

Abubuwan Sinadari

| Daraja | Bangaren%,≤ | ||||||||

| C | Mn | P | S | KuA | NiA | CrA | MoA | VA | |

| S type (bututu mara nauyi) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| E type (Resistance welded bututu) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Nau'in F (Furnace Welded Pipe) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A jimlar waɗannan abubuwa biyar kada ta wuce 1.00%.

B Ga kowane 0.01% raguwa a cikin matsakaicin abun ciki na carbon, matsakaicin abun ciki na manganese an yarda ya karu da 0.06%, amma matsakaicin ba zai iya wuce 1.35%.

C Kowane 0.01% raguwa a cikin matsakaicin abun ciki na carbon zai ba da damar matsakaicin abun ciki na manganese ya karu da 0.06%, amma matsakaicin dole ne ya wuce 1.65%.

Kayan Injiniya

| abu | GR.A | GR.B |

| Ƙarfin ƙarfi, ≥, psi [MPa] Ƙarfin Haɓaka, ≥, psi [MPa] Ma'auni 2in.ko 50mm elongation | 48 000 [330] 30 000 [205] A, B | 60 000 [415] 35 000 [240] A, B |

A Mafi ƙarancin elongation na tsayin ma'auni 2in. (50mm) za a ƙaddara ta hanyar da ke gaba:

e=625000(1940)A0.2/U0.9

e = ƙaramar haɓakar ma'aunin 2in. (50mm), kashi ya zagaye zuwa mafi kusa 0.5%;

A = An ƙididdige shi bisa ga ƙayyadaddun diamita na waje na bututu mai ƙima ko faɗin sunan sunan samfurin tensile da ƙayyadaddun kaurin bangonsa, kuma an zagaya shi zuwa yanki mafi kusa na giciye na samfurin tensile na 0.01 in.2 (1 mm2), kuma ana kwatanta shi da 0.75in.2 (500mm2), ko wacce ta fi karami.

U = ƙayyadaddun ƙayyadaddun ƙarfin ƙarfi, psi (MPa).

B Don haɗuwa daban-daban na nau'o'in nau'ikan gwaji daban-daban da ƙayyadaddun ƙaƙƙarfan ƙarfin ƙarfi, ana nuna ƙaramin ƙarar da ake buƙata a cikin Tebur X4.1 ko Tebu X4.2, gwargwadon iyawarsa.

Bukatar Gwaji

Gwajin tensile, gwajin lankwasawa, gwajin hydrostatic, gwajin walƙiya mara lalacewa.

Ƙarfin Ƙarfafawa

Ikon samarwa: Ton 2000 a kowane wata kowane Gradi na ASTM A53/A53M-2012 Karfe

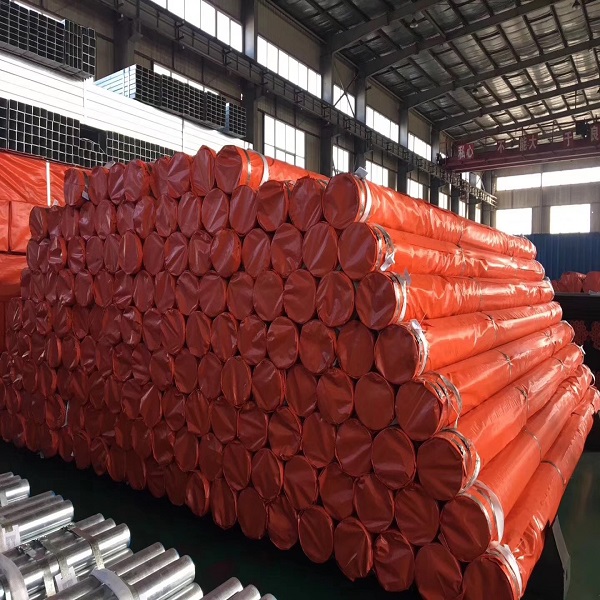

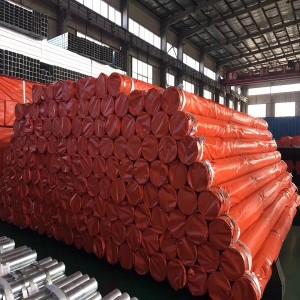

Marufi

A cikin daure da A cikin Akwatin katako mai ƙarfi

Bayarwa

7-14 kwanaki idan a stock, 30-45 kwanaki don samar

Biya

30% depsoit, 70% L/C ko B/L kwafin ko 100% L/C a gani