Galvanized Karfe bututu

Kamfaninmu ya ƙware wajen fitar da bututun ƙarfe mara nauyigalvanized bututu, Bututu Galvanized mara sumul, SMLS galvanized bututu, WELDED galvanized bututu.

Menene bambanci tsakanin hot galvaninzed da sanyi galvanized?

Hot-tsoma galvanizing da sanyi galvanized bambanci:

1. Galvanizing, kuma aka sani da zafi tsoma galvanized, shi ne ingot narke a high yanayin zafi, da dama supplemental abu a wurin, sa'an nan tsoma galvanized karfe tsarin Ramin, da karfe bangaren a Layer na tutiya shafi . A abũbuwan amfãni daga zafi-tsoma galvanizing lalata da ikon, mannewa da taurin tutiya shafi ne mafi alhẽri.

"Cold plated" ko "plating", watau zinc gishiri bayani ta hanyar electrolysis, zuwa plating a kan shafi, kullum ba su da dumama, kananan adadin zinc, da rigar yanayi ne mai sauqi ka fadi a kashe.

2. Hot tsoma galvanized (galvanizing)

Hot-tsoma galvanizing wani sinadari magani, shi ne electrochemical dauki.

Cold galvanizing shine adireshin jiki, kawai goge saman saman tutiya, Layer na zinc yana da sauƙin faɗuwa. Gina a cikin amfani da zafi tsoma galvanizing.

Ci gaba da zafi tsoma galvanizing tsari: karfe → dumama → sanyaya ga zazzabi galvanized galvanized → sanyaya →

Cold galvanized zinc shine kawai 10-50g/m2, juriyarsa na lalata fiye da tsoma mai zafi galvanized mai yawa bambanci. Galvanized ta farashi mai rahusa.

Hot tsoma galvanized karfe jiki ne zafi tsoma galvanized surface a karkashin yanayin da mannewa da karfi, ba sauki fado kashe, ko da yake akwai zafi tsoma.galvanized bututuabin mamaki na lalata, amma a cikin dogon lokaci don saduwa da fasaha, bukatun kiwon lafiya.

3. Bambance-bambancen fasaha

Da farko, shi ne bambanci tsakanin tsari: zafi-tsoma galvanizing ne workpiece degreasing, pickling, dipping, bushewa ruwa nutsewa a cikin zurfafa tutiya wani lokaci, za a iya tashe.

Har ila yau aka sani da electro-galvanized sanyi galvanizing, shi ne don amfani da electrolysis na'urorin aiki yanki ta wurin ragewa, pickling sinadaran post a cikin tutiya gishiri bayani, da kuma haɗa da anode electrolysis kayan aiki; a wuri fadin sassa na tutiya farantin da aka haɗa zuwa electrolysis kayan aiki tabbatacce, iko a kan, amfani da halin yanzu daga cathode zuwa anode na directional motsi na workpiece za a ajiye a cikin wani Layer na zinc.

Tutiya gama da bambanci: babu sanyi galvanized zafi tsoma galvanizing m haske bayyanar, amma kauri na tutiya shafi na sanyi galvanizing al'amurran da zafi-tsoma galvanizing ne 'yan sau. Galvanized lalata juriya shima sau da yawa.

Dubawa

Aikace-aikace

Ana amfani da shi ne musamman don ƙarfi da sassa na matsa lamba, kuma don maƙasudin tururi, ruwa, iskar gas da bututun iska.

Babban Daraja

GR.A, GR.B

Abubuwan Sinadari

| Daraja | Bangaren%,≤ | ||||||||

| C | Mn | P | S | KuA | NiA | CrA | MoA | VA | |

| S type (bututu mara nauyi) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| E type (Resistance welded bututu) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Nau'in F (Furnace Welded Pipe) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A jimlar waɗannan abubuwa biyar kada ta wuce 1.00%.

B Ga kowane 0.01% raguwa a cikin matsakaicin abun ciki na carbon, matsakaicin abun ciki na manganese an yarda ya karu da 0.06%, amma matsakaicin ba zai iya wuce 1.35%.

C Kowane 0.01% raguwa a cikin matsakaicin abun ciki na carbon zai ba da damar matsakaicin abun ciki na manganese ya karu da 0.06%, amma matsakaicin dole ne ya wuce 1.65%.

Kayan Injiniya

| abu | GR.A | GR.B |

| Ƙarfin ƙarfi, ≥, psi [MPa] Ƙarfin Haɓaka, ≥, psi [MPa] Ma'auni 2in.ko 50mm elongation | 48 000 [330] 30 000 [205] A, B | 60 000 [415] 35 000 [240] A, B |

A Mafi ƙarancin elongation na tsayin ma'auni 2in. (50mm) za a ƙaddara ta hanyar da ke gaba:

e=625000(1940)A0.2/U0.9

e = ƙaramar haɓakar ma'aunin 2in. (50mm), kashi ya zagaye zuwa mafi kusa 0.5%;

A = An ƙididdige shi bisa ga ƙayyadaddun diamita na waje na bututu mai ƙima ko faɗin ƙididdiga na samfurin tensile da ƙayyadaddun kaurin bangonsa, kuma an zagaya shi zuwa yanki na giciye mafi kusa na samfurin tensile na 0.01 in.2 (1 mm2), kuma ana kwatanta shi da 0.75in.2 (500mm2), ko wacce ta fi karami.

U = ƙayyadaddun ƙayyadaddun ƙarfin ƙarfi, psi (MPa).

B Don haɗuwa daban-daban na nau'o'in nau'ikan gwaji daban-daban da ƙayyadaddun ƙaƙƙarfan ƙarfin ƙarfi, ana nuna ƙaramin ƙarar da ake buƙata a cikin Tebur X4.1 ko Tebu X4.2, gwargwadon iyawarsa.

Bukatar Gwaji

Gwajin tensile, gwajin lankwasawa, gwajin hydrostatic, gwajin walƙiya mara lalacewa.

Ƙarfin Ƙarfafawa

Ikon samarwa: Ton 2000 a kowane wata kowane Gradi na ASTM A53/A53M-2012 Karfe

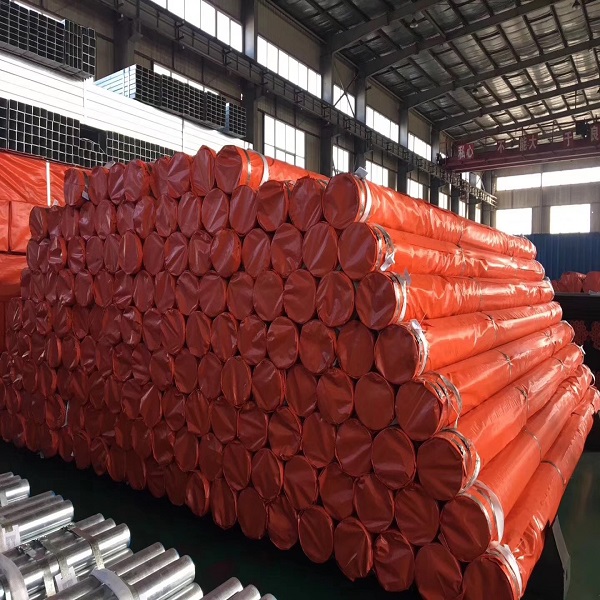

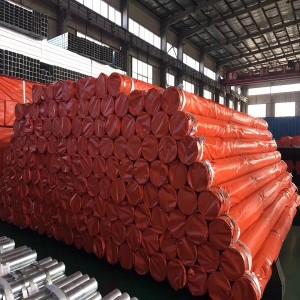

Marufi

A cikin daure da A cikin Akwatin katako mai ƙarfi

Bayarwa

7-14 kwanaki idan a stock, 30-45 kwanaki don samar

Biya

30% depsoit, 70% L/C ko B/L kwafin ko 100% L/C a gani