15Mo3 (15MoG): Bututun ƙarfe ne a cikin daidaitaccen DIN17175. Karamin diamita ne na carbon molybdenum karfe bututu don tukunyar jirgi da superheater, da nau'in lu'u-lu'u mai zafi mai ƙarfi. A cikin 1995, an dasa shi zuwaGB5310kuma mai suna 15MoG. Abubuwan sinadaran sa yana da sauƙi, amma yana ƙunshe da molybdenum, don haka yana da mafi kyawun ƙarfin zafi fiye da carbon karfe yayin da yake riƙe da aikin tsari iri ɗaya kamar carbon karfe. Saboda kyawun aikinsa, farashi mai arha, an yi amfani da shi sosai a duniya. Duk da haka, karfe yana da hali zuwa graphitization bayan dogon lokaci aiki a high zafin jiki, don haka ta aiki zafin jiki ya kamata a sarrafa a kasa 510 ℃, da kuma adadin Al kara da cewa smelting ya kamata a iyakance ga sarrafawa da kuma jinkirta graphitization tsari. An fi amfani da wannan bututun ƙarfe don ƙaramin zafin jiki mai zafi da ƙarancin zafin jiki. Yanayin zafin bango yana ƙasa da 510 ℃. Abubuwan sinadaransa C0.12-0.20, SI0.10-0.35, MN0.40-0.80, S≤0.035, P≤0.035, MO0.25-0.35; Matsayin ƙarfin al'ada σs≥270-285, σb≥450-600 MPa; Plastic delta 22 ko sama da haka.

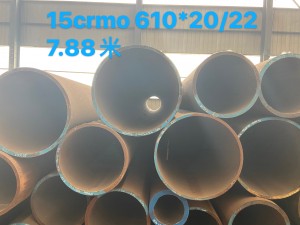

15CrMoG:GB5310-95 karfe (daidai da 1CR-1 / 2Mo da 11/4CR-1 / 2MO-Si karfe yadu amfani a duniya), ta chromium abun ciki ne mafi girma fiye da 12CrMo karfe, don haka yana da mafi girma thermal ƙarfi a 500-550 ℃. Lokacin da zafin jiki ya wuce 550 ℃, ƙarfin thermal na karfe yana raguwa sosai. Lokacin da aka sarrafa na dogon lokaci a 500-550 ℃, graphitization ba ya faruwa, amma carbide spheroidization da alloying kashi redistribution faruwa, wanda kai ga rage da thermal ƙarfi na karfe. The karfe yana da kyau juriya ga shakatawa a 450 ℃. Ayyukansa na bututu da aikin walda yana da kyau. An yafi amfani da matsayin high da matsakaici matsa lamba tururi conduit da hada guda biyu akwatin da tururi siga kasa 550 ℃, superheater tube da bango zafin jiki kasa 560 ℃, da dai sauransu Its sinadaran abun da ke ciki C0.12-0.18, Si0.17-0.37, MN0.40-0.70, S≤0℃, P0.0.0.0. CR0.80-1.10, MO0.40-0.55; A karkashin yanayin yanayi na al'ada, matakin ƙarfin σs≥235, σb≥440-640 MPa; Plastics delta p 21.

T22 (P22), 12Cr2MoG: T22 (P22) su neASME SA213 (SA335) kayan code, waɗanda aka haɗa a cikiGB5310-95. A cikin jerin ƙarfe na CR-Mo, ƙarfin ƙarfin zafin sa yana da inganci, ƙarfin ƙarfin zafin jiki iri ɗaya da damuwa mai ƙyalli fiye da ƙarfe 9CR-1Mo har ma mafi girma, don haka ana amfani da shi sosai a cikin ƙarfin thermal na waje, ikon nukiliya da tasoshin matsa lamba. Koyaya, tattalin arzikin sa na fasaha ya yi ƙasa da 12Cr1MoV ɗinmu, don haka ba a ƙara yin amfani da shi a masana'antar tukunyar tukunyar wuta ta cikin gida. Yi amfani kawai lokacin da ake buƙata (musamman lokacin ƙira da ƙira daidai da lambar ASME). Karfe ba shi da hankali ga maganin zafi kuma yana da babban filastik mai ɗorewa da kyakkyawan aikin walda. T22 kananan diamita tube ne yafi amfani da karfe bango zafin jiki a kasa 580 ℃ superheater da reheater dumama surface tube, da dai sauransu.,P22babban diamita tube ne yafi amfani a karfe bango zafin jiki ne ba fiye da 565 ℃ superheater / reheater hada guda biyu akwatin da babban tururi bututu. Abubuwan sinadaransa C≤0.15, Si≤0.50, MN0.30-0.60, S≤0.025, P≤0.025, CR1.90-2.60, MO0.87-1.13; A karkashin yanayin yanayi na al'ada, matakin ƙarfin σs≥280, σb≥450-600 MPa; Plastic delta 20 ko fiye.

12Cr1MoVG:GB5310-95 nano misali karfe, shine babban matsa lamba na cikin gida, matsananciyar matsananciyar matsa lamba, babban tukunyar tukunyar tukunyar jirgi mai zafi, akwatin tarin da babban bututun tururi da aka yi amfani da shi sosai. A sinadaran abun da ke ciki da inji Properties na 12Cr1MoV farantin ne m guda. Its sinadaran abun da ke ciki ne mai sauki, jimlar gami abun ciki ne kasa da 2%, ga low carbon, low gami pearlescent irin zafi ƙarfi karfe. Vanadium na iya samar da barga carbide VC tare da carbon, wanda zai iya yin chromium da molybdenum a cikin ƙarfe fifiko sun kasance a cikin ferrite, kuma yana rage saurin canja wurin chromium da molybdenum daga ferrite zuwa carbide, ta yadda ƙarfe ya fi kwanciyar hankali a babban zafin jiki. A total adadin alloyed abubuwa a cikin wannan karfe ne kawai rabin 2.25 CR-1Mo karfe amfani da ko'ina a kasashen waje, amma m ƙarfi a 580 ℃ da 100,000 h ne 40% mafi girma fiye da na karshen. Bugu da ƙari, tsarin samarwa yana da sauƙi kuma aikin walda yana da kyau. Muddin tsarin kula da zafi yana da tsauri, ana iya gamsu da cikakken aikin da ƙarfin ƙarfin zafi. Ainihin aiki na tashar wutar lantarki ya nuna cewa 12Cr1MoV babban bututun tururi har yanzu ana iya amfani da shi bayan aikin aminci a 540 ℃ na sa'o'i 100,000. Babban diamita bututu da aka yafi amfani da tarin akwatin da babban tururi conduit na tururi siga a kasa 565 ℃, da kuma kananan diamita tube da ake amfani da tukunyar jirgi dumama surface tube na karfe bango zafin jiki kasa 580 ℃.

12Cr2MoWVTiB (G102):GB5310-95 a cikin karfe, domin kasar Sin ta ci gaba a cikin 1960s, low carbon, low gami (ƙananan adadin bambancin) Bainite irin zafi ƙarfi karfe, daga 1970s aka kunshe a cikin Ma'aikatar Metallurgical Industry misali YB529-70 da kuma yanzu kasa misali, a karshen 1980 da karfe ta hanyar Ma'aikatar wutar lantarki da Ma'aikatar Metallu. ganewa. The karfe yana da kyau m inji Properties, da thermal ƙarfi da kuma sabis zafin jiki ne mafi girma fiye da na irin wannan karafa a kasashen waje, kai matakin wasu chromium-nickel austenitic karfe a 620 ℃. Wannan shi ne saboda karfe ya ƙunshi nau'o'in abubuwa masu haɗawa da yawa, kuma an ƙara don inganta juriya na abubuwa kamar Cr, Si, don haka matsakaicin zafin sabis na iya isa 620 ℃. Ainihin aikin tashar wutar lantarki ya nuna cewa tsari da kaddarorin bututun karfe ba sa canzawa da yawa bayan aiki na dogon lokaci. An yafi amfani dashi azaman superheater tube da reheater tube don matsananci-high siga tukunyar jirgi tare da karfe zafin jiki ≤620 ℃. Abubuwan sinadaransa C0.08-0.15, Si0.45-0.75, MN0.45-0.65, S≤0.030, P≤0.030, CR1.60-2.10, MO0.50-0.65, V0.28-0.42,0.5.0.08-W. B0.002-0.008; A karkashin yanayin yanayi na al'ada, matakin ƙarfin σs≥345, σb≥540-735 MPa; Plastics delta p 18.

Sa-213t91335P91): Lambar karfe a cikiASME SA-213(335) misali. An haɓaka ta Rubber Ridge National Laboratory of the United States of America, amfani da makamashin nukiliya (kuma za a iya amfani da a wasu al'amurran) high zafin jiki matsawa aka gyara na kayan, da karfe dogara ne a kan T9 (9CR-1MO) karfe, a cikin iyaka na carbon abun ciki, mafi tsananin sarrafa abun ciki na P da S da sauran sauran abubuwa a lokaci guda, wani sabon nau'i na ferritic zafi-resistant gami da kara adadin karfe da aka kafa ta hanyar kara adadin karfe. 0.030-0.070% N, 0.18-0.25% V da 0.06-0.10% Nb don saduwa da buƙatun gyaran hatsi. Yana daASME SA-213shafi daidaitaccen karfe, wanda aka dasa a cikinGB5310misali a cikin 1995 kuma darajar shine 10Cr9Mo1VNb. Matsayin duniya ISO/DIS9399-2 an jera shi azaman X10 CRMOVNB9-1.

Saboda babban abun ciki na chromium (9%), juriya na iskar shaka, juriya na lalata, ƙarfin zafin jiki mai girma da halayen rashin graphitization sun fi na ƙananan ƙarfe ƙarfe. Molybdenum (1%) galibi yana haɓaka ƙarfin zafin jiki mai ƙarfi kuma yana hana yanayin ƙyalli mai zafi na chromium karfe. Idan aka kwatanta da T9, da waldi da thermal gajiya Properties an inganta, da m ƙarfi a 600 ℃ ne sau uku cewa na karshen, da kyau kwarai high-zazzabi lalata juriya na T9 (9CR-1Mo) karfe ne kiyaye. Idan aka kwatanta da austenitic bakin karfe, da fadada coefficient ne kananan, thermal watsin ne mai kyau, kuma yana da mafi girma m ƙarfi (kamar tare da TP304 austenitic karfe rabo, har sai da karfi zafin jiki ne 625 ℃, daidai danniya zafin jiki ne 607 ℃). Saboda haka, yana da mafi m inji Properties, barga tsarin da kaddarorin kafin da kuma bayan tsufa, mai kyau waldi da tsari Properties, high m ƙarfi da hadawan abu da iskar shaka juriya. An fi amfani dashi don superheater da reheater tare da zafin jiki na ƙarfe ≤650 ℃ a cikin tukunyar jirgi. Abubuwan sinadaransa C0.08-0.12, Si0.20-0.50, MN0.30-0.60, S≤0.010, P≤0.020, CR8.00-9.50, MO0.85-1.05, V0.18-0.25, V0.18-0.25, Al0.04-0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0. N0.03-0.07; A ƙarƙashin yanayin yanayin zafi na al'ada, matakin ƙarfin σs≥415, σb≥585 MPa; Plastic delta 20 ko fiye.

Lokacin aikawa: Satumba-07-2022