Bututun karfe maras sumul yana ratsawa da dukkan karfen zagaye, sannan bututun karfen da babu walda a saman ana kiran bututun karfe maras sumul. Dangane da hanyar samar da bututun karfen, za a iya raba bututun karfen da ba su da kyau zuwa bututun karfe mai zafi mai zafi, bututun karfe mai sanyi, bututun karfe mai sanyi, bututun karfe mai fitar da bututu, jacking bututu da dai sauransu. Dangane da sifar sashe, bututun ƙarfe mara nauyi ya kasu kashi biyu: zagaye da siffa. Matsakaicin diamita shine 900mm kuma mafi ƙarancin diamita shine 4mm. Dangane da amfani daban-daban, akwai bututun ƙarfe maras kauri da bango mai kauri da bututun ƙarfe mara nauyi. An fi amfani da bututun ƙarfe mara ƙarfi don bututun hakowa na ƙasa, petrochemicalfasa bututu, bututun tukunyar jirgi, mai ɗaukar bututu dahigh-daidaici tsarin karfe bututudon motoci, tarakta da jirgin sama.

Dangane da amfani da aka raba zuwa general manufa (ga ruwa, gas bututun da tsarin sassa, inji sassa) da kuma na musamman (ga boilers, geological bincike, bearings, acid juriya, da dai sauransu.) biyu Categories.

A general manufa sumul karfe bututu da aka yi birgima da talakawa carbon tsarin karfe, low gami tsarin karfe ko gami tsarin karfe, kuma yana da mafi girma fitarwa, yafi amfani a matsayin bututu ko tsarin sashi domin isar ruwa. Akwai nau'ikan bututu da yawa don dalilai na musamman, kamar bututu maras nauyi, bututun wutar lantarki, bututun da ba su da tushe da kuma bututun mai. Bututun ƙarfe maras sumul yana da ɓangaren giciye kuma ana amfani da shi sosai azaman bututun isar da ruwa, kamar bututun isar da mai, iskar gas, iskar gas, ruwa da wasu ƙaƙƙarfan kayan aiki.

Tsarin samar da bututu mara ƙarfi:

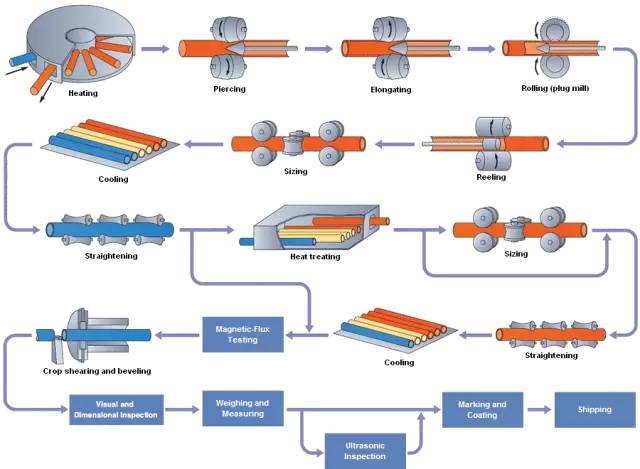

① Babban samar da tsari na zafi-birgima sumul karfe bututu (△ Babban dubawa tsari):

Shiri da dubawa

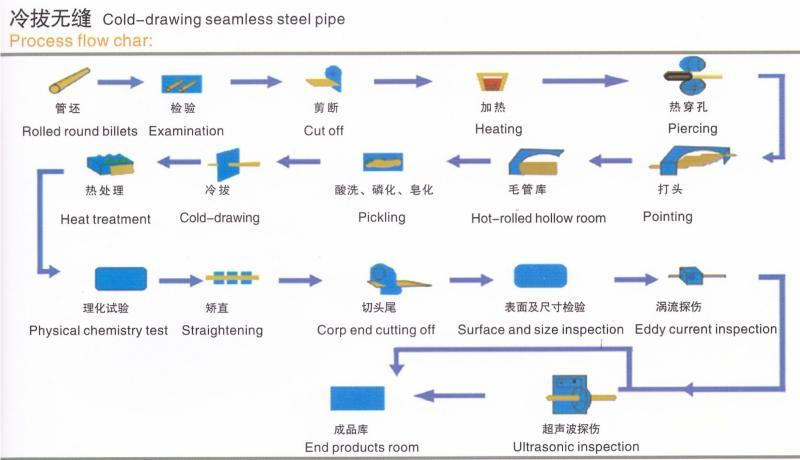

② Cold birgima (jawo) m karfe bututu main samar tsari:

Shirye-shirye mara kyau → man shafawa → Juyawa sanyi (zane) → Maganin zafi → daidaitawa → gamawa → dubawa

Janar m karfe bututu samar tsari za a iya raba iri biyu sanyi zane da zafi mirgina, sanyi birgima sumul karfe bututu samar tsari ne kullum mafi hadaddun fiye da zafi mirgina, da tube billet farko da wani gudanar da wani uku nadi ci gaba da mirgina, extrusion bayan sizing gwajin, idan surface bai amsa ga crack bayan zagaye tube da za a yanke da yankan na'ura, yankan girma na game da daya mita blank. Sa'an nan kuma shigar da tsari na annealing, annealing tare da acidic ruwa pickling, pickling ya kamata a kula da ko akwai babban adadin kumfa a saman, idan akwai babban adadin kumfa, yana nuna cewa ingancin bututun karfe ba zai iya cika ka'idodi masu dacewa ba. Fitowar bututun karfen da ba shi da sanyi ya fi na bututun karfe mai zafi, kaurin bangon bututun karfen da ba shi da kyau gaba daya ya fi na bututun karfen da aka yi birgima, amma fuskar ta yi haske fiye da na bututun karfe mai kauri mai kauri, fuskar ba ta da kauri sosai, kuma caliber din ba shi da yawa sosai.

Ana isar da yanayin isar da bututun ƙarfe mara nauyi mai zafi gabaɗaya bayan zafi mai birgima. Hot birgima sumul karfe bututu bayan ingancin dubawa je ta hanyar ma'aikatan ta m manual selection, bayan ingancin dubawa don gudanar da wani surface man, sa'an nan kuma bi da dama sanyi zane gwaji, zafi mirgina jiyya don gudanar da gwajin perforation, idan perforation kara girma ne ma girma da zama straightener. Bayan an daidaita, ana aika shi zuwa injin gano aibi ta na'urar watsawa don gwajin gano aibi, kuma a ƙarshe an yi mata lakabi, tsara da sanya shi a cikin sito.

Zagaye tube blank → dumama → perforation → uku-yi skew mirgina, ci gaba da mirgina ko extrusion → Stripping → sizing (ko rage) → Cooling → mikewa → ruwa matsa lamba gwajin (ko dubawa) → Alama → Sumul karfe bututu a cikin ajiya an yi da karfe ingot ko m bututu blank ta hanyar perforation, sanyi capilla da kuma yi sanyi bututu don yin. Ƙayyadaddun ƙayyadaddun bututun ƙarfe maras kyau suna bayyana ta wurin diamita na waje * kauri na bangon millimeters.

A waje diamita na zafi-birgima sumul bututu ne kullum girma fiye da 32mm, bango kauri ne 2.5-200mm, da m diamita na sanyi-birgima sumul karfe bututu iya zama 6mm, bango kauri iya zama 0.25mm, da m diamita na bakin ciki-walled bututu iya zama 5mm, bango kauri ne kasa da 0.5mm girma dabam, fiye da 02000000000 girman girman girman girman girman girman girman ba. bututu.

Lokacin aikawa: Agusta-28-2023