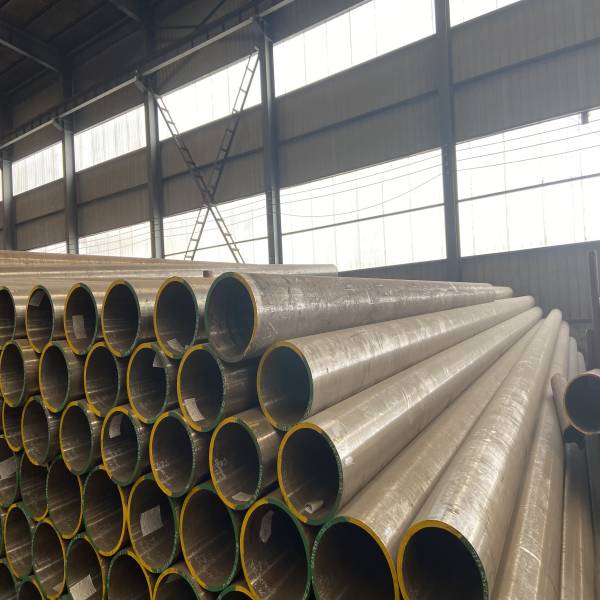

ʻO ka maikaʻi maikaʻi loa A335 P91 P22 P36 High Pressure Boiler Heat Exchange Alloy Seamless Steel Pipe

ʻIke nui ʻia a hilinaʻi ʻia kā mākou mau hopena e nā mea kūʻai aku a e hui pū me ka hoʻomohala mau ʻana i nā koi kālā a me ka pilikanaka no ka maikaʻi maikaʻi loa A335 P91 P22 P36 High Pressure Boiler Heat Exchange Alloy Seamless Steel Pipe, ʻO kā mākou ʻōlelo "ʻO nā kumukūʻai kūpono, ka manawa hana kūleʻa a me ka lawelawe maikaʻi loa. ” Manaʻo mākou e hui pū me nā mea kūʻai aku he nui no ka ulu like ʻana a me nā uku.

ʻIke ʻia a hilinaʻi nui ʻia kā mākou mau hoʻonā e nā mea kūʻai aku a e hui pū me ka hoʻomohala mau ʻana i nā koi kālā a me ka pilikanakaKina P91 a me P22, Ua paʻa mākou e hoʻokō i kāu mau pono āpau a hoʻoponopono i nā pilikia ʻenehana āu e hālāwai ai me kāu mau mea ʻenehana. ʻO kā mākou hāʻina kūʻokoʻa a me ka ʻike nui o ka ʻenehana e hoʻolilo iā mākou i koho i makemake ʻia no kā mākou mea kūʻai.

Nānā nui

| Kūlana: ASTM A335 | Alloy a ʻAʻole: Alloy |

| Pūʻulu Papa: P5,P9,P11,P22,P91, P92 Etc. | Noi: Paipu Boiler |

| Mānoanoa: 1 – 100 Mm | Ili lapaau: E like me ka Customer koi |

| Ka Anawaena o waho (Ka puni): 10 – 1000 Mm | ʻenehana: Huki ʻia ʻo Wela/ Huki Anu |

| Ka lōʻihi: ka lōʻihi paʻa a i ʻole ka lōʻihi like ʻole | Hoʻomaʻamaʻa wela: Annealing / Normalizing / Tempering |

| ʻAno ʻāpana: Poe | Paipu Kūikawā: Paipu Pā mānoanoa |

| Kahi i kumu: Kina | Hoʻohana: High Pressure Steam Pipe, Boiler and Heat Exchanger |

| Palapala hōʻoia: ISO9001:2008 | Hoʻāʻo: ET/UT |

Palapala noi

Hoʻohana nui ʻia ia e hana i ke kiʻekiʻe o ka alloy steel boiler pipe, heat exchanged pipe, high pressure steam pipe no ka ʻaila a me ka ʻoihana kemika.

Papa Nui

Papa o ke kiʻekiʻe-koʻikoʻi alloy paipu![]() 5,P9,P11,P22,P91,P92 etc

5,P9,P11,P22,P91,P92 etc

Mea Kimia

| Papa | UN | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| Sequiv. | ||||||||

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | – | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10-0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00-6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00-2.00 | 4.00-6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00-6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50-1.00 | 8.00-10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50-1.00 | 1.00-1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | – | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.02 | 0.01 | 0.20~0.50 | 8.00-9.50 | 0.85-1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.02 | 0.01 | 0.5 | 8.50-9.50 | 0.30~0.60 |

He inoa hou i hoʻokumu ʻia e like me ka Practice E 527 a me SAE J1086, Practice for Numbering Metals and Alloys (UNS). Loaʻa i ka papa B 5c ka maʻiʻo titanium ʻaʻole i emi iho ma mua o 4 manawa o ka maʻiʻo kalapona a ʻaʻole i oi aku ma mua o 0.70 %; a i ʻole he maʻiʻo columbium o 8 a 10 manawa o ka maʻiʻo kalapona.

Waiwai Mechanical

| Nā waiwai mīkini | P1,P2 | P12 | P23 | P91 | P92,P11 | P122 |

| Ka ikaika tensile | 380 | 415 | 510 | 585 | 620 | 620 |

| E hāʻawi i ka ikaika | 205 | 220 | 400 | 415 | 440 | 400 |

Hoʻomaʻamaʻa Wela

| Papa | ʻAno Hana Wela | Hoʻomaʻamaʻa maʻamau ʻo F [C] | Subcritical Annealing or Tempering |

| P5, P9, P11, a me P22 | Kaulana Mahana F [C] | ||

| A335 P5 (b,c) | Hoʻopiha piha a i ʻole Isothermal Anneal | ||

| Normalize a me ka Mahana | ***** | 1250 [675] | |

| Hoʻohui Kūʻē (P5c wale nō) | ***** | 1325 – 1375 [715 - 745] | |

| A335 P9 | Hoʻopiha piha a i ʻole Isothermal Anneal | ||

| Normalize a me ka Mahana | ***** | 1250 [675] | |

| A335 P11 | Hoʻopiha piha a i ʻole Isothermal Anneal | ||

| Normalize a me ka Mahana | ***** | 1200 [650] | |

| A335 P22 | Hoʻopiha piha a i ʻole Isothermal Anneal | ||

| Normalize a me ka Mahana | ***** | 1250 [675] | |

| A335 P91 | Normalize a me ka Mahana | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Hoʻopiʻi me ka huhū | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

Hoʻomanawanui

No ka paipu i kauoha ʻia i ke anawaena o loko, ʻaʻole e ʻokoʻa ke anawaena o loko ma mua o 6 1% mai ke anawaena o loko i ʻōlelo ʻia.

ʻAe ʻia nā ʻokoʻa ma waho o ke anawaena

| NPS mea koho | in | mm | in | mm |

| 1⁄8a 11⁄2, me | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Ma luna o 11⁄2 a hiki i 4, incl. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Ma luna o 4 a hiki i 8, incl | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Ma luna o 8 a 12, incl. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Ma luna o 12 | 6 1 % o ka mea i hoakakaia waho anawaena |

Koi hoao

Hōʻike Hydraustatic:

Pono e ho'āʻoʻia ka paipu kila me ka hydraulic hoʻokahi. ʻO 20 MPa ka mana hoʻāʻo kiʻekiʻe loa. Ma lalo o ke kaomi ho'āʻo, ʻaʻole i emi iho ka manawa hoʻokūpaʻa ma mua o 10 S, a ʻaʻole pono e kahe ka paipu kila.

Ma hope o ka ʻae ʻana o ka mea hoʻohana, hiki ke hoʻololi ʻia ka Hydraulic Test e ka Eddy Current Testing or Magnetic Flux Leakage Testing.

Ho'āʻo Nondestructive:

ʻO nā paipu e koi ana i ka nānā hou aʻe e pono ke nānā ʻia me ka Ultrasonically. Ma hope o ke kūkākūkā ʻana e koi ʻia ka ʻae ʻana o ka ʻaoʻao a ua kuhikuhi ʻia i loko o ka ʻaelike, hiki ke hoʻohui ʻia nā hoʻāʻo hoʻopōʻino ʻole.

Ho'āʻo palahalaha:

ʻO nā paipu me ka anawaena waho i ʻoi aku ma mua o 22 mm e hoʻāʻo ʻia i ka hoʻāʻo ʻana. ʻAʻole ʻike ʻia ka Delamination, nā kiko keʻokeʻo, a i ʻole nā mea haumia i ka wā o ka hoʻokolohua holoʻokoʻa.

Ho'āʻo paʻakikī:

No ka paipu o nā Papa P91, P92, P122, a me P911, Brinell, Vickers, a i ʻole Rockwell e hana ʻia nā hoʻāʻo paʻakikī ma kahi hōʻailona mai kēlā me kēia ʻāpana.

Hoʻāʻo Bend:

No ka paipu nona ka anawaena i oi aku i ka NPS 25 a o kona anawaena me ka manoanoa o ka paia he 7.0 a emi mai paha e hoao ia i ka hoao piko ma kahi o ka hoao palahalaha. Hiki ke hā'awi 'ia ka paipu 'ē a'e nona ke anawaena a 'oi aku paha ma mua o NPS 10 i ka ho'ā'o pi'o ma kahi o ka ho'ā'o palahalaha ma muli o ka 'ae o ka mea kū'ai.

Huahana Huahana

wikiō

Paipu paila

GB/T5310-2017

ASME SA-106/SA-106M-2015

ASTMA210(A210M)-2012

ASME SA-213/SA-213M

ASTM A335/A335M-2018

ʻIke nui ʻia a hilinaʻi ʻia kā mākou mau hopena e nā mea kūʻai aku a e hui pū me ka hoʻomohala mau ʻana i nā koi kālā a me ka pilikanaka no ka maikaʻi maikaʻi loa A335 P91 P22 P36 High Pressure Boiler Heat Exchange Alloy Seamless Steel Pipe, ʻO kā mākou ʻōlelo "ʻO nā kumukūʻai kūpono, ka manawa hana kūleʻa a me ka lawelawe maikaʻi loa. ” Manaʻo mākou e hui pū me nā mea kūʻai aku he nui no ka ulu like ʻana a me nā uku.

ʻOi aku ka maikaʻiKina P91 a me P22, Ua paʻa mākou e hoʻokō i kāu mau pono āpau a hoʻoponopono i nā pilikia ʻenehana āu e hālāwai ai me kāu mau mea ʻenehana. ʻO kā mākou hāʻina kūʻokoʻa a me ka ʻike nui o ka ʻenehana e hoʻolilo iā mākou i koho i makemake ʻia no kā mākou mea kūʻai.

ASTM A335 P5he paipu wela kiʻekiʻe o ka maʻamau ʻAmelika. ʻO ka paipu Alloy kahi ʻano o ka paipu kila maʻemaʻe, ʻoi aku ka kiʻekiʻe o kāna hana ma mua o ka pahu kila maʻemaʻe, no ka mea, ʻoi aku ka nui o C i kēia ʻano o ka paipu kila, ʻoi aku ka liʻiliʻi o ka hana ma mua o ka paipu kila seamless maʻamau, no laila ua hoʻohana nui ʻia ka paipu alloy. i ka aila, aerospace, kemika, ka mana uila, ka paila, ka pūʻali koa a me nā ʻoihana ʻē aʻe.

Loaʻa i ka paipu Alloy Steel ka nui o nā mea ʻē aʻe ma waho o ke kalapona e like me ka nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium a me nā helu liʻiliʻi o nā mea i ʻae ʻia e like me ka manganese, sulfur, silicon, a me ka phosphorous.

E like me ke kila kila kūloko: 1Cr5Mo GB 9948-2006 "Seamless Steel Pipe Standard for Petroleum Cracking"

- Uku: 30% Waihona, 70% L/C A i ʻole B/L kope a i ʻole 100% L/C ma ka ʻike.

- Min.Order Nui:1 PC

- Hiki ke hoʻolako: Makahiki 20000 Tons Inventory Of Steel Pipe

- Ke alakaʻi manawa: 7-14 mau lā inā i loko o ka waihona, 30-45 mau lā e hana ai

- Hoʻopili: Nalo ʻeleʻele, Bevel a me ka pāpale no kēlā me kēia paipu hoʻokahi; OD Ma lalo o 219mm Pono e hoʻopaʻa i loko o ka pūʻolo, a ʻo kēlā me kēia pūpū ʻaʻole i ʻoi aku ma mua o 2 mau tona.

Nānā nui

| Kūlana:ASTM A335 | Alloy a ʻAʻole: Alloy |

| Pūʻulu Papa: P5 | Noi: Paipu Boiler |

| Mānoanoa: 1 – 100 Mm | Ili lapaau: E like me ka Customer koi |

| Ka Anawaena o waho (Ka puni): 10 – 1000 Mm | ʻenehana: Huki ʻia ʻo Wela/ Huki Anu |

| Ka lōʻihi: ka lōʻihi paʻa a i ʻole ka lōʻihi like ʻole | Hoʻomaʻamaʻa wela: Annealing / Normalizing / Tempering |

| ʻAno ʻāpana: Poe | Paipu Kūikawā: Paipu Pā mānoanoa |

| Kahi i kumu: Kina | Hoʻohana: High Pressure Steam Pipe, Boiler and Heat Exchanger |

| Palapala hōʻoia: ISO9001:2008 | Hoʻāʻo: ET/UT |

Palapala noi

Hoʻohana nui ʻia no ka hana ʻana i ke kiʻekiʻe kiʻekiʻe Alloy Steel Boiler Pipe, Heat Exchanged Pipe, High Pressure Steam Pipe No ka ʻaila a me ka ʻoihana ʻoihana.

Mea Kimia

| Nā haku mele | ʻIkepili |

| ʻO ka koho ʻana o UNS | K41545 |

| Kalapona(max.) | 0.15 |

| Manganese | 0.30-0.60 |

| Phosphorus(max.) | 0.025 |

| Silikon(max.) | 0.50 |

| Chromium | 4.00-6.00 |

| Molybdenum | 0.45-0.65 |

| Nā mea ʻē aʻe | … |

Waiwai Mechanical

| Waiwai | ʻIkepili |

| Ikaika U'i, Min, (MPa) | 415 Mpa |

| Ka ikaika hua, min, (MPa) | 205 Mpa |

| Elongation, Min, (%), L/T | 30/20 |

Hoʻomaʻamaʻa Wela

| Papa | ʻAno Hana Wela | Hoʻomaʻamaʻa maʻamau ʻo F [C] | Subcritical Annealing A i ʻole Tempering |

| P5, P9, P11, a me P22 | Kaulana Mahana F [C] | ||

| A335 P5 (B,C) | Piha A i ʻole Isothermal Anneal | ||

| A335 P5b | Hoʻomaʻamaʻa a me ka huhū | ***** | 1250 [675] |

| A335 P5c | ʻO Anneal Subcritical | ***** | 1325 – 1375 [715 - 745] |

Hoʻomanawanui

No ka paipu i kauoha ʻia i loko o ke anawaena, ʻaʻole e ʻokoʻa ke anawaena o loko ma mua o ±1 % mai ka anawaena o loko i ʻōlelo ʻia.

ʻAe ʻia nā ʻokoʻa ma waho o ke anawaena

| NPS mea koho | Hoʻomanawanui maikaʻi | hoʻomanawanui ʻino | ||

| In | Mm | In | Mm | |

| 1⁄8 a hiki i 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Ma luna o 11⁄2 i 4, Incl. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Ma luna o 4 a 8, Incl | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Ma luna o 8 a 12, Incl. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Ma luna o 12 | ±1 % o ka mea i hoakakaia Mawaho Anawaena | |||

Koi hoao

Hōʻike Hydraustatic:

Pono e ho'āʻoʻia ka paipu kila me ka hydraulic hoʻokahi. ʻO 20 MPa ka mana hoʻāʻo kiʻekiʻe loa. Ma lalo o ke kaomi ho'āʻo, ʻaʻole i emi iho ka manawa hoʻokūpaʻa ma mua o 10 S, a ʻaʻole pono e kahe ka paipu kila.

Ma hope o ka ʻae ʻana o ka mea hoʻohana, hiki ke hoʻololi ʻia ka Hydraulic Test e ka Eddy Current Testing or Magnetic Flux Leakage Testing.

Ho'āʻo Nondestructive:

ʻO nā paipu e koi ana i ka nānā hou aʻe e pono ke nānā ʻia me ka Ultrasonically. Ma hope o ke kūkākūkā ʻana e koi ʻia ka ʻae ʻana o ka ʻaoʻao a ua kuhikuhi ʻia i loko o ka ʻaelike, hiki ke hoʻohui ʻia nā hoʻāʻo hoʻopōʻino ʻole.

Ho'āʻo palahalaha:

ʻO nā paipu me ka anawaena waho i ʻoi aku ma mua o 22 mm e hoʻāʻo ʻia i ka hoʻāʻo ʻana. ʻAʻole ʻike ʻia ka Delamination, nā kiko keʻokeʻo, a i ʻole nā mea haumia i ka wā o ka hoʻokolohua holoʻokoʻa.

Ho'āʻo paʻakikī:

No ka paipu o nā papa P91, P92, P122, a me P911, Brinell, Vickers, a i ʻole Rockwell, e hana ʻia nā hoʻāʻo paʻakikī ma luna o kahi kikoʻī mai kēlā me kēia ʻāpana.

Hoʻāʻo Bend:

No ka paipu nona ka anawaena i oi aku i ka NPS 25 a nona ka anawaena o ka manoanoa o ka paia he 7.0 a emi mai paha e hoao ia i ka hoao Bend ma kahi o ka hoao flattening. ʻO nā paipu ʻē aʻe nona ka anawaena like a ʻoi aku paha ma mua o NPS 10 hiki ke hāʻawi ʻia i ka hoʻāʻo Bend ma kahi o ka hoʻāʻo flattening ma lalo o ka ʻae ʻana o ka mea kūʻai.

Mea & Hana

Hiki ke wela a huki ʻia paha ka paipu me ka hoʻoponopono wela i hōʻike ʻia ma lalo nei.

Hoʻomaʻamaʻa Wela

- A / N+T

- N+T / Q+T

- N+T

Hōʻike ʻia nā hoʻokolohua Mechanical

- ʻO ka hoʻāʻo ʻana i ka ʻāʻī a i ʻole ka Longitudinal Tension Test and Flattening Test, Hardness Test, a i ʻole Bend Test

- No nā mea wela i mālama ʻia i loko o ka umu ahi ʻano pū, e hoʻāʻo ʻia ma ka 5% o ka paipu mai kēlā me kēia ʻāpana i mālama ʻia. No nā ʻāpana liʻiliʻi, e hoʻāʻo ʻia ma kahi o hoʻokahi paipu.

- No ka wela wela i mālama ʻia e ke kaʻina hana mau, e hana ʻia nā hoʻāʻo ma ka helu kūpono o ka paipu e lilo i 5% o ka hailona, akā ʻaʻole i emi iho ma mua o 2 paipu.

Nā memo no ka ho'āʻo ʻo Bend:

- No ka paipu nona ka anawaena i oi aku i ka NPS 25 a o kona anawaena me ka manoanoa o ka paia he 7.0 a emi mai paha e hoao ia i ka hoao piko ma kahi o ka hoao palahalaha.

- Hiki ke hā'awi 'ia ka paipu 'ē a'e i like ke anawaena a 'oi aku paha ma mua o NPS 10 ma kahi o ka ho'ā'o palahalaha ma muli o ka 'ae o ka mea kū'ai.

- E hoʻopiʻi ʻia nā mea hoʻāʻo piʻo ma ka lumi wela a hiki i 180 me ka ʻole o ka haki ʻana ma waho o ka ʻāpana piʻo.

ASTM A335 P5He kūpono nā paipu kila ʻole no ka wai, ka mahu, ka hydrogen, ka ʻaila ʻawaʻawa, a me nā mea ʻē aʻe.℃; Ke hoʻohana ʻia i ka ʻoihana hana e like me ka aila ʻawaʻawa, maikaʻi ke kūpaʻa sulfur corrosion kiʻekiʻe, a hoʻohana pinepine ʻia i nā kūlana corrosion sulfur kiʻekiʻe o 288 ~ 550℃.

Kaʻina hana:

1. 'Owili wela (extruded seamless paipu kila): poepoe paipu billet → wela → perforation → ekolu-roll kea olokaa, hoomau olokaa 'ole extrusion → paipu wehe 'ana → nui (ai 'ole e ho'ēmi) → hoʻoluʻu → hoʻopololei → wai kaomi ho'āʻo (aiʻole defect detection). ) → māka → waiho

2. Kiʻi anu (ʻolokaʻa) paipu kila maʻemaʻe: puʻupuʻu pōʻai billet → hoʻomehana → perforation → poʻomanaʻo → annealing → pickling → ʻaila ʻaila (kaupaʻa keleawe) → kiʻi anuanu (cold rolling) → paipu blank → mālama wela → hoʻopololei → wai ho'āʻo kaomi (ʻike hewa) → māka → waiho

Nā hiʻohiʻona noiʻi:

I loko o ka lewa a me ka ʻenekini no ka hana ʻana i ka aila ʻaila kiʻekiʻe-sulfur,ASTM A335 P5Hoʻohana nui ʻia nā paipu kila ʻole no nā paipu lalo o nā hale kiaʻi a me nā hale kiaʻi, nā umu ahi o ka lewa a me nā kapuahi, nā ʻāpana kiʻekiʻe o ka lewa a me ka ʻaila hoʻololi ʻana i nā laina a me nā ʻaila kiʻekiʻe kiʻekiʻe a me nā paipu kinoea i loaʻa i ka sulfur.

Ma nā ʻāpana FCC,ASTM A335 P5Hoʻohana nui ʻia nā paipu kila maʻemaʻe i ka slurry kiʻekiʻe, catalyst a me ka hoʻihoʻi ʻana i nā pipelines hoʻomaʻemaʻe, a me kekahi mau pipelines sulfur kiʻekiʻe.

I ka hui coking lohi,ASTM A335 P5Hoʻohana nui ʻia ka paipu kila maʻemaʻe no ke kiʻekiʻe o ka wela wela ma lalo o ka hale kiaʻi coke a me ke kiʻekiʻe wela o ka aila a me ka paipu kinoea ma luna o ka hale kiaʻi coke, ka paipu umu ma lalo o ka umu coke, ka paipu ma lalo o ka hale kiaʻi fracking a me nā mea ʻē aʻe. kiʻekiʻe wela ka aila a me ke kinoea paipu i loko o ka sulfur.

Loaʻa i ka paipu Alloy Steel ka nui o nā mea ʻē aʻe ma waho o ke kalapona e like me ka nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium a me nā helu liʻiliʻi o nā mea i ʻae ʻia e like me ka manganese, sulfur, silicon, a me ka phosphorous..

ASTM A335 P9 he paipu wela kiʻekiʻe o ka maʻamau ʻAmelika. ʻO ka paipu Alloy kahi ʻano o ka paipu kila maʻemaʻe, ʻoi aku ka kiʻekiʻe o kāna hana ma mua o ka pahu kila maʻemaʻe, no ka mea, ʻoi aku ka nui o C i kēia ʻano o ka paipu kila, ʻoi aku ka liʻiliʻi o ka hana ma mua o ka paipu kila seamless maʻamau, no laila ua hoʻohana nui ʻia ka paipu alloy. i ka aila, aerospace, kemika, ka mana uila, ka paila, ka pūʻali koa a me nā ʻoihana ʻē aʻe.

A335 P9he kila wela wela chromium-molybdenum i hana ʻia e like me ke kūlana ʻAmelika. Ma muli o kona kūpaʻa maikaʻi loa, ka ikaika wela a me ka sulfide corrosion resistance, hoʻohana nui ʻia ia i ke kiʻekiʻe kiʻekiʻe a me ke kiʻekiʻe kiʻekiʻe o ka inflammable a me nā paipu pahū o nā mea kanu hoʻomaʻemaʻe ʻaila, ʻoi aku ka pololei o ka paipu wela o ka umu wela, hiki i ka mahana wela ke hiki i 550 ~ 600 ℃ .

E like me ke kila kila kūloko: 1Cr5Mo GB 9948-2006 "Seamless Steel Pipe Standard for Petroleum Cracking"

Nānā nui

| Kūlana:ASTM A335 | Alloy a ʻAʻole: Alloy |

| Pūʻulu Papa: P9 | Noi: Paipu Boiler |

| Mānoanoa: 1 – 100 Mm | Ili lapaau: E like me ka Customer koi |

| Ka Anawaena o waho (Ka puni): 10 – 1000 Mm | ʻenehana: Huki ʻia ʻo Wela/ Huki Anu |

| Ka lōʻihi: ka lōʻihi paʻa a i ʻole ka lōʻihi like ʻole | Hoʻomaʻamaʻa wela: Annealing / Normalizing / Tempering |

| ʻAno ʻāpana: Poe | Pipe Pecial: Paipu Pā mānoanoa |

| Kahi i kumu: Kina | Hoʻohana: High Pressure Steam Pipe, Boiler and Heat Exchanger |

| Palapala hōʻoia: ISO9001:2008 | Hoʻāʻo: ET/UT |

Mea Kimia

ʻO ka hana kemika o nā paipu kila maʻemaʻe no ka haki ʻana o ka ʻaila

| ASTM A335M | C | SI | Mn | P | S | Cr | Mo |

| P9 | ≦0.15 | 0.25-1.00 | 0.30-0.60 | ≦0.025 | ≦0.025 | 8.00-10.00 | 0.90-1.10 |

Waiwai Mechanical

| Waiwai | ʻIkepili |

| Ka ikaika uʻi, min, (MPa) | 415 Mpa |

| Ka ikaika hua, min, (MPa) | 205 Mpa |

| Elongation, min, (%), L/T | 14 |

| HB | 180 |

Hoʻomaʻamaʻa Wela

|

Papa | ʻAno Hana Wela | Hoʻomaʻamaʻa maʻamau ʻo F [C] | Subcritical Annealing A i ʻole Tempering |

| P5, P9, P11, a me P22 | |||

| A335 P9 | Piha A i ʻole Isothermal Anneal | ||

| Hoʻomaʻamaʻa a me ka huhū | ***** | 1250 [675] |

A335 P9hiki ke mālama ʻia ka wela e ka annealing a i ʻole ka hana maʻamau + tempering. He lohi ke kaʻina hana Annealing, hoʻopilikia i ke kaʻina hana, paʻakikī ke kaʻina hana, a me ke kumukūʻai kiʻekiʻe; No laila, ʻaʻole hoʻohana ka hana maoli i ke kaʻina hana annealing wela, hoʻohana pinepine i ka normalizing + tempering heat treatment ma mua o ke kaʻina hana annealing, e hoʻokō i ka hana ʻoihana.

A335 P9kila no ka mea, ʻaʻole i loaʻa iā V, Nb a me nā mea microalloying ʻē aʻe, no laila ʻoi aku ka haʻahaʻa o ka mahana maʻamau ma mua o A335 P91 kila, 950 ~ 1050 ℃, paʻa no 1h, ke kaʻina hana i ka wā maʻamau ka hapa nui o ka carbide i hoʻoheheʻe ʻia akā ʻaʻole i maopopo ka ulu ʻana o ka palaoa, akā. ʻO ke kiʻekiʻe kiʻekiʻe o ka maʻamau maʻamau ua maʻalahi i ka palaoa austenite coarse: ʻo ka mahana wela he 740-790 ℃, i mea e loaʻa ai ka paʻakikī haʻahaʻa, pono e hooloihiia ka manawa mahana hoohuoi.

Hoʻomanawanui

No ka paipu i kauoha ʻia i loko o ke anawaena, ʻaʻole e ʻokoʻa ke anawaena o loko ma mua o ±1 % mai ka anawaena o loko i ʻōlelo ʻia.

ʻAe ʻia nā ʻokoʻa ma waho o ke anawaena

| NPS mea koho | Hoʻomanawanui maikaʻi | hoʻomanawanui ʻino | ||

| In | Mm | In | Mm | |

| 1⁄8 a hiki i 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Ma luna o 11⁄2 i 4, Incl. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Ma luna o 4 a 8, Incl | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Ma luna o 8 a 12, Incl. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Ma luna o 12 | ±1 % o ka mea i hoakakaia | |||

Kaʻina hana:

Hoʻolālā ʻia ʻo A335 e like me ke kūlana lako o ka paipu kila Tianjin a me nā ʻano oA335 P9kila P9 ho'āʻo-hana kaʻina hana o ka seamless kila paipu:Hana ʻia ka umu ahi uila → hoʻomaʻemaʻe ladle → hoʻoheheʻe ʻia → hoʻoheheʻe ʻia → hoʻoheheʻe ʻia → hoʻoheheʻe ʻia → hoʻoheheʻe ʻana i ka pahu → hoʻomehana ʻana o ka pahu → oblique piercing → PQF mau ʻo ka ʻōwili ʻana o ka pahu wili wili → ʻekolu ʻōwili nui → ka hoʻoluʻu ʻana o ka moena → ka hopena o ka paipu. ʻoki → hoʻopololei i ka paipu kila → ʻike leakage flux → hoʻōla wela → hoʻopololei → ʻike hewa kani ultrasonic → hoʻāʻo hydraulic → ka nui a me ka nānā ʻana i nā hiʻohiʻona → mālama.

hana hana:

| Helu mea | hana hana | Ka Hana a me ka Mana Pono | |||

| 1 | Halawai makaikai | Minute o ka halawai | |||

| 2 | ASEA-SKF | Hoʻoponopono i ka haku mele | |||

| *Ka helu ʻana i ka haku mele | |||||

| *mahana hoohehee | |||||

| 3 | CCM | billet | |||

| 4 | Nānā mea maka | Ka nānā ʻana a me ka hōʻoia ʻana i ka maikaʻi | |||

| * Ke kūlana hiʻohiʻona: ʻAʻole pono ka ʻili o ka billet i nā hemahema e like me ka scarring, slag, pinholes, māwae, a me nā mea ʻē aʻe. | |||||

| 5 | Pumehana hakahaka | ʻO ka hoʻomehana ʻana i nā billet i loko o ka umu ahi | |||

| * Mālama i ka mahana wela | |||||

| 6 | ka puka ʻana o ka paipu | ʻOkuʻi me kahi kuʻi papa kuhikuhi/alakaʻi | |||

| *E hoʻomalu i ka mahana i ka wā e hou ai | |||||

| * E hoʻomalu i ka nui ma hope o ka perforation | |||||

| 7 | ʻO Kaʻa Wela | ʻO ka ʻōwili wela ma nā hale wili paipu mau | |||

| * Hoʻonohonoho i ka mānoanoa pā paipu | |||||

| 8 | Nui | E hoʻomalu i ke anawaena o waho a me nā ana mānoanoa o ka paia | |||

| * Hoʻopiha piha i ka anawaena o waho | |||||

| * ʻO ka mīkini mānoanoa pā piha | |||||

| 9 | haku mele | ʻIkepili haku mele | |||

| * Nā ʻae ʻana no ka haku mele ʻana. Pono e hoʻopaʻa ʻia nā hopena o ka hoʻopili ʻana i ka haku mele ma ka puke mea. | |||||

| 10 | Hoʻomaʻamaʻa + hoʻomāmā | Hana ʻia ka mālama wela (normalizing) ma hope o ka ʻōwili wela. Pono ka mālama wela i ka mālama ʻana i ka mahana a me ka lōʻihi. | |||

| Ma hope o ka mālama ʻana i ka wela, pono e hoʻokō nā waiwai mechanical o ka huahana i ka maʻamau ASTM A335 | |||||

| 11 | hooluolu ea | Moena hooluu kaupae | |||

| 12 | ʻili ʻili | Ke ʻeli ʻana i ka lōʻihi i ʻōlelo ʻia | |||

| * Ka mana lōʻihi paipu kila | |||||

| 13 | Ka pololei (inā pono) | Kāohi i ka palahalaha. | |||

| Ma hope o ka hoʻopololei ʻana, pono ka pololei e like me ASTM A335 | |||||

| 14 | Nānā a ʻae ʻia | ʻO ke ʻano a me ka nānā ʻana | |||

| * Pono nā ʻae ʻana o ke kila kila me ka ASTM A999 | |||||

| Nānā: ʻO ke anawaena o waho ke ahonui: ±0.75%D | |||||

| * Pono e hoʻokō ʻia ka nānā ʻana i nā hiʻohiʻona e like me ka maʻamau ASTM A999 e pale i ka ʻili maikaʻi ʻole. | |||||

| 15 | ʻike hemahema | * Pono e nānā ʻia ke kino holoʻokoʻa o ka paipu kila no nā hemahema lōʻihi e like me ISO9303/E213 | |||

| Ka ho'āʻo ultrasonic: | |||||

| 16 | Hoʻāʻo waiwai mīkini | (1) Ho'āʻo Tensile (longitudinal) a me ka ho'āʻo palahalaha | |||

| ʻO ka pinepine nānā | 5% / pūʻulu, ma ka liʻiliʻi 2 paipu | ||||

| Min | Max | ||||

| P9 | Ka ikaika hua (Mpa) | 205 | |||

| ikaika uʻi (MPa) | 415 | ||||

| ʻO ka elongation | Wahi a ASTM A335 maʻamau | ||||

| ʻO ka hoʻokolohua palahalaha | Wahi a ASTM A999 maʻamau | ||||

| (2) Hoao paakiki | |||||

| Ka pinepine ho'āʻo: like me ka ho'āʻo tensile | 1 ʻāpana / ʻāpana | ||||

| HV&HRC | ≤250HV10&≤25 HRC HV10≤250&HRC≤25 | ||||

| 'Ōlelo Aʻo: Vickers paakiki ho'āʻo maʻamau: ISO6507 a ASTM E92; | |||||

| ʻO ke kūlana hoʻāʻo paʻakikī ʻo Rockwell: ISO6508 a i ʻole ASTM E18 | |||||

| 17 | NDT | E ho'āʻo ʻia kēlā me kēia paipu kila e like me nā koi o nā ʻano hoʻokolohua E213, E309 a i ʻole E570. | |||

| 18 | hoʻāʻo paʻa wai | ʻO ka hoʻāʻo hydrostatic e like me ka ASTM A999, ka hoʻāʻo ʻana | |||

| 19 | bevel | ʻO ka beveling kūpono o nā welau ʻelua o ka paipu kila e like me ASTM B16.25fig.3(a) | |||

| 20 | Ana o ke kaumaha a me ka loa | *Ka hoʻomanawanui kaumaha hoʻokahi: -6%~ +4%. | |||

| 21 | Kūlana paipu | E hōʻailona ʻia ka ʻili o waho o ka paipu kila e like me ka maʻamau ASTM A335 a me nā koi o ka mea kūʻai aku. Penei ka hoailona ana. | |||

| “Loihi Kaumaha TPCO ASTM A335 Makahiki-Mahina Ana P9 S LT**C ***MPa/NDE Heat Number Lot Number Tube Number | |||||

| 22 | pena | Ua pena ʻia ka ʻili o waho o ka paipu e like me ke kūlana o ka hale hana | |||

| 23 | pāpale hope paipu | ** Pono e loaʻa nā pāpale plastik ma nā kihi ʻelua o kēlā me kēia paipu | |||

| 24 | papa inoa mea | *Pono e hāʻawi ʻia ka puke waiwai e like me EN10204 3.1. "Pono e hōʻike ʻia ka PO mea kūʻai aku ma ka puke waiwai. | |||

ASTM A335 P11 he paipu wela kiʻekiʻe o ka maʻamau ʻAmelika. ʻO ka paipu Alloy kahi ʻano o ka paipu kila maʻemaʻe, ʻoi aku ka kiʻekiʻe o kāna hana ma mua o ka pahu kila maʻemaʻe, no ka mea, ʻoi aku ka nui o C i kēia ʻano o ka paipu kila, ʻoi aku ka liʻiliʻi o ka hana ma mua o ka paipu kila seamless maʻamau, no laila ua hoʻohana nui ʻia ka paipu alloy. i ka aila, aerospace, kemika, ka mana uila, ka paila, ka pūʻali koa a me nā ʻoihana ʻē aʻe.

Nānā nui

| Kūlana:ASTM A335 | Alloy a ʻAʻole: Alloy |

| Pūʻulu Papa: P11 | Noi: Paipu Boiler |

| Mānoanoa: 1 – 100 Mm | Ili lapaau: E like me ka Customer koi |

| Ka Anawaena o waho (Ka puni): 10 – 1000 Mm | ʻenehana: Huki ʻia ʻo Wela/ Huki Anu |

| Ka lōʻihi: ka lōʻihi paʻa a i ʻole ka lōʻihi like ʻole | Hoʻomaʻamaʻa wela: Annealing / Normalizing / Tempering |

| ʻAno ʻāpana: Poe | Pipe Pecial: Paipu Pā mānoanoa |

| Kahi i kumu: Kina | Hoʻohana: High Pressure Steam Pipe, Boiler and Heat Exchanger |

| Palapala hōʻoia: ISO9001:2008 | Hoʻāʻo: ET/UT |

Mea Kimia

ʻO ka hana kemika o nā paipu kila maʻemaʻe no ka haki ʻana o ka ʻaila

| C | SI | Mn | P | S | Cr | Mo | |

| P11 | 0.05-0.15 | 0.5-1.00 | 0.30-0.61 | 0.025 | 0.025 | 1.00-1.50 | 0.44-0.65 |

Waiwai Mechanical

| Waiwai | ʻIkepili |

| Ka ikaika uʻi, min, (MPa) | 415 Mpa |

| Ka ikaika hua, min, (MPa) | 205Mpa |

Hoʻomaʻamaʻa Wela

|

Papa | ʻAno Hana Wela | Hoʻomaʻamaʻa maʻamau ʻo F [C] | Subcritical Annealing A i ʻole Tempering |

| P5, P9, P11, a me P22 | |||

| A335 P11 | Piha A i ʻole Isothermal Anneal | ||

| Hoʻomaʻamaʻa a me ka huhū | ***** | 1250[650] |

Hoʻomanawanui

No ka paipu i kauoha ʻia i loko o ke anawaena, ʻaʻole e ʻokoʻa ke anawaena o loko ma mua o ±1 % mai ka anawaena o loko i ʻōlelo ʻia.

ʻAe ʻia nā ʻokoʻa ma waho o ke anawaena

| NPS mea koho | Hoʻomanawanui maikaʻi | hoʻomanawanui ʻino | ||

| In | Mm | In | Mm | |

| 1⁄8 a hiki i 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Ma luna o 11⁄2 i 4, Incl. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Ma luna o 4 a 8, Incl | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Ma luna o 8 a 12, Incl. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Ma luna o 12 | ±1 % o ka mea i hoakakaia | |||

ASTM A335 P22he paipu kila hoʻoheheʻe ʻole ʻia no ka hoʻohana ferritic wela kiʻekiʻe. ʻO ka paipu Alloy kahi ʻano o ka paipu kila maʻemaʻe, ʻoi aku ka kiʻekiʻe o kāna hana ma mua o ka pahu kila maʻemaʻe, no ka mea, ʻoi aku ka nui o C i kēia ʻano o ka paipu kila, ʻoi aku ka liʻiliʻi o ka hana ma mua o ka paipu kila seamless maʻamau, no laila ua hoʻohana nui ʻia ka paipu alloy. i ka aila, aerospace, kemika, ka mana uila, ka paila, ka pūʻali koa a me nā ʻoihana ʻē aʻe.

Nānā nui

| Kūlana:ASTM A335 | Alloy a ʻAʻole: Alloy |

| Pūʻulu Papa: P22 | Noi: Paipu Boiler |

| Mānoanoa: 1 – 100 Mm | Ili lapaau: E like me ka Customer koi |

| Ka Anawaena o waho (Ka puni): 10 – 1000 Mm | ʻenehana: Huki ʻia ʻo Wela/ Huki Anu |

| Ka lōʻihi: ka lōʻihi paʻa a i ʻole ka lōʻihi like ʻole | Hoʻomaʻamaʻa wela: Annealing / Normalizing / Tempering |

| ʻAno ʻāpana: Poe | Pipe Pecial: Paipu Pā mānoanoa |

| Kahi i kumu: Kina | Hoʻohana: High Pressure Steam Pipe, Boiler and Heat Exchanger |

| Palapala hōʻoia: ISO9001:2008 | Hoʻāʻo: ET/UT |

Mea Kimia

ʻO ka hana kemika o nā paipu kila maʻemaʻe no ka haki ʻana o ka ʻaila

| C | SI | Mn | P | S | Cr | Mo | |

| P22 | 0.05-0.15 | 0.5 | 0.30-0.60 | 0.025 | 0.025 | 1.90-2.60 | 0.87-1.13 |

Waiwai Mechanical

| Waiwai | ʻIkepili |

| Ka ikaika uʻi, min, (MPa) | 415 Mpa |

| Ka ikaika hua, min, (MPa) | 205Mpa |

Hoʻomaʻamaʻa Wela

|

Papa | ʻAno Hana Wela | Hoʻomaʻamaʻa maʻamau ʻo F [C] | Subcritical Annealing A i ʻole Tempering |

| P5, P9, P11, a me P22 | |||

| A335 P22 | Piha A i ʻole Isothermal Anneal | ||

| Hoʻomaʻamaʻa a me ka huhū | ***** | 1250[650] |

Hoʻomanawanui

No ka paipu i kauoha ʻia i loko o ke anawaena, ʻaʻole e ʻokoʻa ke anawaena o loko ma mua o ±1 % mai ka anawaena o loko i ʻōlelo ʻia.

ʻAe ʻia nā ʻokoʻa ma waho o ke anawaena

| NPS mea koho | Hoʻomanawanui maikaʻi | hoʻomanawanui ʻino | ||

| In | Mm | In | Mm | |

| 1⁄8 a hiki i 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Ma luna o 11⁄2 i 4, Incl. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Ma luna o 4 a 8, Incl | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Ma luna o 8 a 12, Incl. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Ma luna o 12 | ±1 % o ka mea i hoakakaia | |||

ʻO A335 P22 he 2.25Cr-1Mo Chromium-molybdenum kiʻekiʻe Temperature ferritic steel no nā paila a me nā mea hoʻomehana wela,ASTM A335/A335Mmaʻamau. I ka makahiki 1985, ua hoʻololi ʻia i GB5310 a kapa ʻia ʻo 12Cr2MoG. Loaʻa i nā ʻāina ʻē aʻe nā māka kila like, e like me ka Federal Republic of Germany 10CrMo910 a me Iapana STBA24. I loko o ka cr-1Mo steel series, ʻoi aku ka kiʻekiʻe o kona ikaika wela, ma lalo o ka mahana like (ka wela≤580℃) ʻoi aku ka kiʻekiʻe o kona ikaika haʻihaʻi a me ke koʻikoʻi i ʻae ʻia ma mua o ke kila 9CR-1Mo, a he hana maikaʻi kāna hana a me ka hana kuʻi ʻana, ka plasticity lōʻihi maikaʻi. No laila, ua hoʻohana nui ʻia i loko o ka ʻoihana hana koʻikoʻi, e like me ka mana wela, ka mana nuklea a me kekahi mau mea hydrogen i nā paipu hoʻomehana like ʻole a me nā kīʻaha kiʻekiʻe.

ʻAe ʻia ka mahana: A335P22 (SA-213T22) i hoʻohana nui ʻia ma 300,600MW a me nā mea nui ʻē aʻe o ka mana nui o ka mea kanu boiler tube pā wela.≤580℃ka wela wela a me ka wela o ka paia paipu & LT;540℃paipu mahu paia a me ke poʻo, ua hoʻohana nui ʻia kēia ʻano kila ma ʻAmelika Hui Pū ʻIa, Iapana a me ʻEulopa, he mōʻaukala lōʻihi o ka hana ʻana i nā mea kanu mana, he hana paʻa, hana maikaʻi ka hana o ke kila makua.

12Cr1MoV kila no ka chromium-molybdenum vanadium kila vanadium kila, hoʻohana nui ʻia no ka paipu kila 12Cr1MoV/GB5310. Hoʻohana nui ʻia, ʻo ia ka mahana ma 480℃~580℃wahi wela kiʻekiʻe me kekahi o nā mea nui loa. 12Cr1MoVG kila paipu lawelawe wela: ua hoʻohana nui ia no ke kila nui o ka superheater paipu, poʻo a me ka mahu paipu o kiʻekiʻe puʻupuʻu boiler nona ka paipu pā wela emi ma mua o 580.℃.

Kaʻina hana: ho'āʻo paʻakikī:

1. 'Owili wela (extruded seamless paipu kila): poepoe paipu billet → wela → perforation → ekolu-roll kea olokaa, hoomau olokaa 'ole extrusion → paipu wehe 'ana → nui (ai 'ole e ho'ēmi) → hoʻoluʻu → hoʻopololei → wai kaomi ho'āʻo (aiʻole defect detection). ) → māka → waiho

2. Kiʻi anu (ʻolokaʻa) paipu kila maʻemaʻe: puʻupuʻu pōʻai billet → hoʻomehana → perforation → poʻomanaʻo → annealing → pickling → ʻaila ʻaila (kaupaʻa keleawe) → kiʻi anuanu (cold rolling) → paipu blank → mālama wela → hoʻopololei → wai ho'āʻo kaomi (ʻike hewa) → māka → waiho

Hoʻopili:

Hoʻopaʻa haʻahaʻa/puʻi puʻupuʻu/puʻi pahu/pale lāʻau ma nā ʻaoʻao ʻelua o nā paipu a mālama pono ʻia no ka lawe ʻana i ke kai kūpono a i ʻole ke noi ʻia.

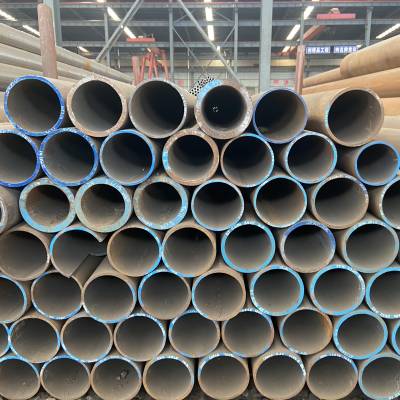

Nānā nui

P92 maʻamau kiʻekiʻe wela wela paipu seamless alloy paipu.

| Kūlana:ASTM A335 | Alloy a ʻAʻole: Alloy |

| Pūʻulu Papa: P92 | Noi: Paipu Boiler |

| Mānoanoa: 1 – 100 Mm | Ili lapaau: E like me ka Customer koi |

| Ka Anawaena o waho (Ka puni): 10 – 1000 Mm | ʻenehana: Huki ʻia ʻo Wela/ Huki Anu |

| Ka lōʻihi: ka lōʻihi paʻa a i ʻole ka lōʻihi like ʻole | Hoʻomaʻamaʻa wela: Annealing / Normalizing / Tempering |

| ʻAno ʻāpana: Poe | Pipe Pecial: Paipu Pā mānoanoa |

| Kahi i kumu: Kina | Hoʻohana: High Pressure Steam Pipe, Boiler and Heat Exchanger |

| Palapala hōʻoia: ISO9001:2008 | Hoʻāʻo: ET/UT |

Mea Kimia

ʻO ka hana kemika o nā paipu kila maʻemaʻe no ka haki ʻana o ka ʻaila

| C | SI | Mn | P | S | Cr | Mo | |

| P92 | 0.07-0.13 | 0.5 | 0.30-0.60 | 0.02 | 0.01 | 8.50-9.5 | 0.30-0.60 |

Waiwai Mechanical

| Waiwai | ʻIkepili |

| Ka ikaika uʻi, min, (MPa) | 620 Mpa |

| Ka ikaika hua, min, (MPa) | 440Mpa |

Hoʻomaʻamaʻa Wela

|

Papa | ʻAno Hana Wela | Hoʻomaʻamaʻa maʻamau ʻo F [C] | Subcritical Annealing A i ʻole Tempering |

| P5, P9, P11, a me P22 | |||

| A335 P92 | Piha A i ʻole Isothermal Anneal | ||

| Hoʻomaʻamaʻa a me ka huhū | ***** | 1250[675] |

Hoʻomanawanui

No ka paipu i kauoha ʻia i loko o ke anawaena, ʻaʻole e ʻokoʻa ke anawaena o loko ma mua o ±1 % mai ka anawaena o loko i ʻōlelo ʻia.

ʻAe ʻia nā ʻokoʻa ma waho o ke anawaena

| NPS mea koho | Hoʻomanawanui maikaʻi | hoʻomanawanui ʻino | ||

| In | Mm | In | Mm | |

| 1⁄8 a hiki i 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Ma luna o 11⁄2 i 4, Incl. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Ma luna o 4 a 8, Incl | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Ma luna o 8 a 12, Incl. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Ma luna o 12 | ±1 % o ka mea i hoakakaia | |||