ASME SA-106 / SA-106M-2015 Carbon steel yeeb nkab

| Txheem:ASTM SA 106 | Alloy los tsis: Tsis yog |

| Qib: GR.A, GR.B, GR.C thiab lwm yam | Daim ntawv thov: Cov yeeb nkab ua kua |

| Thickness: 1-100 hli | Kev kho deg: Raws li cov neeg siv khoom xav tau |

| Sab nraud txoj kab uas hla (Round): 10 - 1000 mm | Cov txheej txheem: Kub Rolled |

| Length: Tsau ntev lossis random ntev | Kev kho cua sov: Annealing / normalizing |

| Tshooj Shape: Round | Cov yeeb nkab tshwj xeeb: Kub kub |

| Qhov chaw ntawm Keeb Kwm: Suav teb | Siv: Kev tsim kho, kev thauj mus los |

| Ntawv pov thawj: ISO9001: 2008 | Test: ECT/CNV/NDT |

Seamless steel yeeb nkab rau kev ua haujlwm kubASTM A106 1, haum rau qhov kub thiab txias, Nws yog dav siv hauv roj av, tshuaj lom neeg kev lag luam, boiler, fais fab chaw nres tsheb, nkoj, machinery manufacturing, tsheb, aviation, aerospace, zog, geology, kev tsim kho thiab tub rog kev lag luam thiab lwm yam lag luam.

Qib ntawm cov khoom zoo carbon steel: GR.A, GR.B, GR.C

| Kev sib xyaw, % | |||

| Qib A | Qib B | Qib C | |

| Cov pa roj carbon, max | 0.25 A | 0.3b ib | 0, 35b |

| Manganese | 0.27-0.93 Nws | 0.29-1.06 Nws | 0.29-1.06 Nws |

| Phosphorus, max | 0.035 ib | 0.035 ib | 0.035 ib |

| Sulfur, max | 0.035 ib | 0.035 ib | 0.035 ib |

| Silicon, min | 0.10 | 0.10 | 0.10 |

| Chrome, maxC | 0.40 Nws | 0.40 Nws | 0.40 Nws |

| tooj liab, maxC | 0.40 Nws | 0.40 Nws | 0.40 Nws |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 Nws | 0.40 Nws | 0.40 Nws |

| Vanadium, maxC | 0.08 ib | 0.08 ib | 0.08 ib |

| A Rau txhua qhov kev txo qis ntawm 0.01% qis dua qhov siab tshaj plaws, qhov nce ntawm 0.06% manganese saum toj no qhov siab tshaj plaws yuav raug tso cai mus txog qhov siab tshaj ntawm 1.35%. | |||

| B Tshwj tsis yog tias tau teev tseg los ntawm tus neeg yuav khoom, rau txhua qhov txo qis ntawm 0.01% qis dua cov pa roj carbon siab tshaj plaws, qhov nce ntawm 0.06% manganese saum toj kawg nkaus yuav raug tso cai mus txog qhov siab tshaj ntawm 1.65%. | |||

| C Cov tsib yam ua ke no yuav tsum tsis pub tshaj 1%. | |||

| Qib A | Qib B | Qib C | ||||||

| Tensile zog, min, psi (MPa) | 48 000 (330) | 60 000 (415) | 70 000 (485) | |||||

| Yield zog, min, psi (MPa) | 30 000 (205) | 35 000 (240) | 40 000 (275) | |||||

| Ntev | Transverse | Ntev | Transverse | Ntev | Transverse | |||

| Elongation hauv 2 nti (50 mm), min, % Basic yam tsawg kawg nkaus elongation transverse strip xeem, thiab rau tag nrho cov me me xeem nyob rau hauv tag nrho seem | 35 | 25 | 30 | 16.5 ib | 30 | 16.5 ib | ||

| Thaum tus qauv puag ncig 2-hauv. (50-mm) gauge length test qauv yog siv | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Rau longitudinal strip xeem | A | A | A | |||||

| Rau kev kuaj kab hlaws, txiav tawm rau txhua 1/32-hauv. (0.8-mm) txo cov phab ntsa thickness hauv qab 5/16 nyob rau hauv. (7.9 mm) los ntawm qhov yooj yim elongation ntawm cov feem pua ntawm cov hauv qab no yuav tsum tau ua | 1.25 | 1.00 Nws | 1.00 Nws | |||||

| A Qhov tsawg kawg nkaus elongation nyob rau hauv 2 in. (50 mm) yuav tsum tau txiav txim los ntawm cov nram qab no kab zauv: | ||||||||

| e = 625000A 0.2 / U 0.9 | ||||||||

| rau inch-phaus units, thiab | ||||||||

| e = 1940A 0.2 / U 0.9 | ||||||||

| rau SI units, | ||||||||

| qhov twg: e = yam tsawg kawg nkaus elongation nyob rau hauv 2 nyob rau hauv. (50 mm), %, sib npaug rau qhov ze tshaj 0.5%, A = cross-sectional area of the nro test specimen, in.2 (mm2), raws li tau teev tseg sab nraud txoj kab uas hla los yog nominal teev sab nraud txoj kab uas hla los yog nominal specimen dav thiab teev phab ntsa thickness, sib npaug mus rau qhov ze tshaj 0.01 in.2 (1 mm2). (Yog hais tias thaj tsam li xam yog sib npaug los yog ntau dua 0.75 in.2 (500 mm2), ces tus nqi 0.75 in.2 (500 mm2) yuav tsum tau siv.), thiab U = teev tensile zog, psi (MPa). | ||||||||

Ntxiv nrog rau kev ua kom muaj cov tshuaj lom neeg muaj pes tsawg leeg thiab cov khoom siv kho tshuab, kev sim hydrostatic tau ua ib qho los ntawm ib qho, thiab kev sim flaring thiab flattening yog ua. . Tsis tas li ntawd, muaj qee qhov yuav tsum tau ua rau microstructure, grain loj, thiab decarburization txheej ntawm cov yeeb nkab steel tiav.

Muaj peev xwm muab khoom: 1000 Tons Ib Hlis Ib Qib ntawm ASTM SA-106 Hlau Yeeb Nkab

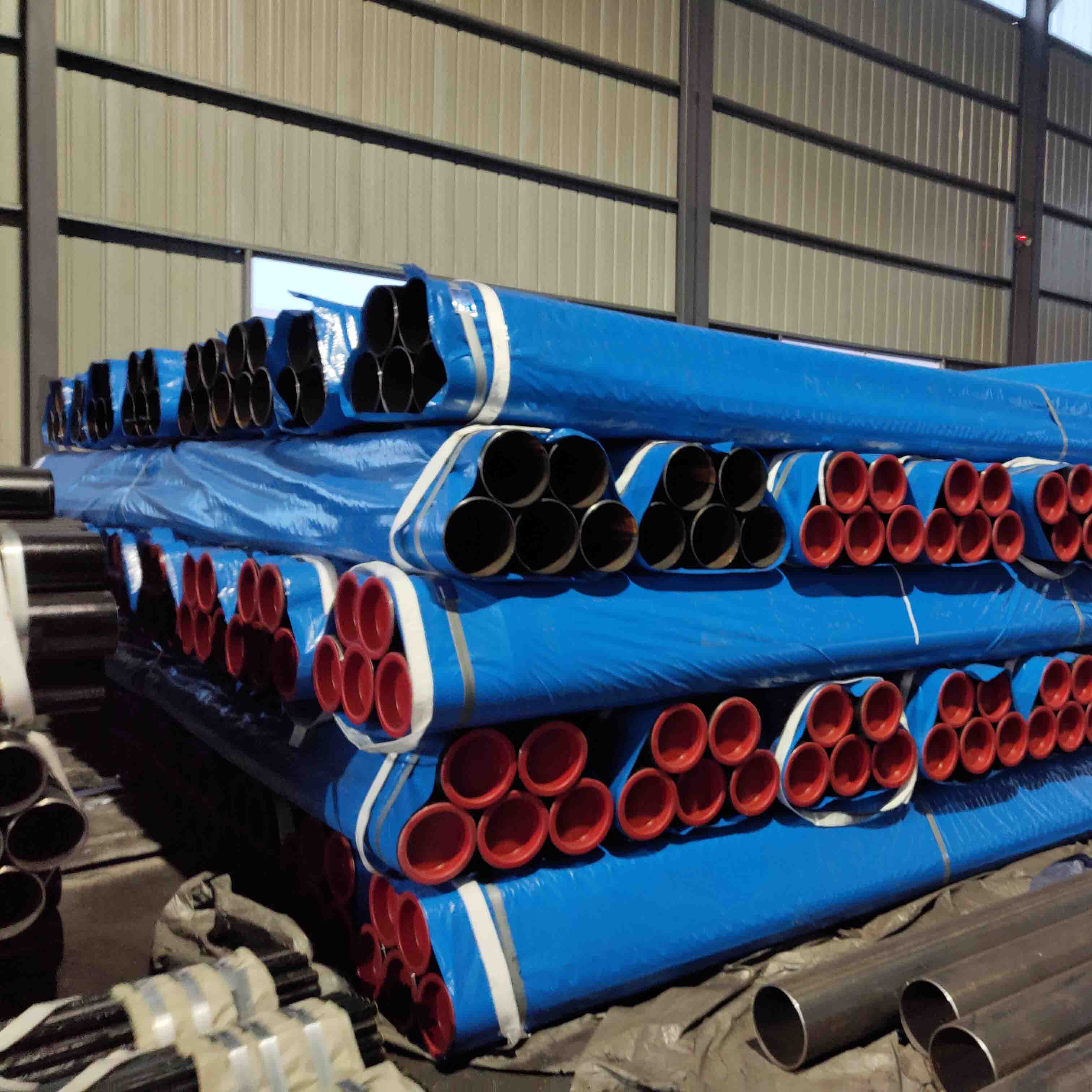

Nyob rau hauv Bundles Thiab Nyob rau hauv lub zog ntoo thawv

7-14 hnub yog nyob rau hauv Tshuag, 30-45 hnub los tsim

30% tso nyiaj, 70% L / C lossis B / L daim ntawv lossis 100% L / C thaum pom