1. Taw qhia rauseamless steel yeeb nkab

Seamless steel yeeb nkab yog cov yeeb nkab steel nrog lub hollow cross-section thiab tsis muaj seams nyob ib ncig ntawm nws. Nws muaj lub zog siab, corrosion kuj thiab zoo thermal conductivity. Vim nws txoj kev ua tau zoo heev, seamless steel kav yog siv dav hauv ntau yam xws liroj av, kev lag luam tshuaj, hluav taws xob, thiabkev tsim kho.

2. Seamless steel yeeb nkab ntau lawm txheej txheem

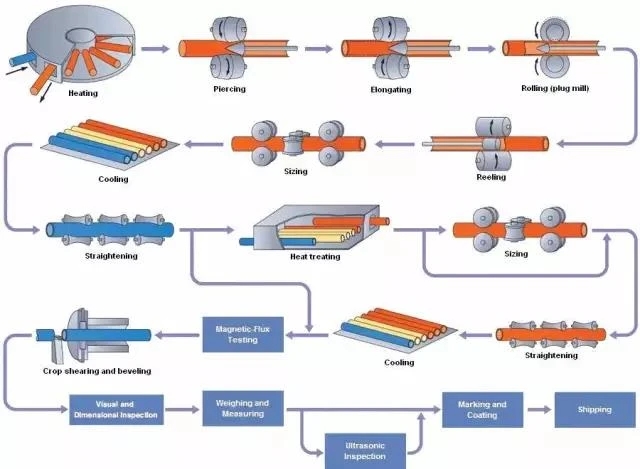

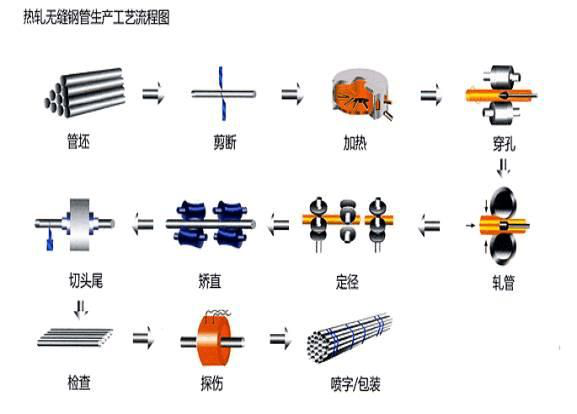

Cov txheej txheem ntau lawm ntawm seamless steel yeeb nkab feem ntau suav nrog cov kauj ruam hauv qab no:

a. Npaj cov ntaub ntawv raw: Xaiv cov hlau uas tsim nyog, uas yuav tsum tau ua kom du, tsis muaj npuas, tsis muaj kab nrib pleb, thiab tsis muaj qhov tsis xws luag.

b. Cua sov: Cua sov cov hlau billet kom kub siab kom nws cov yas thiab yooj yim rau daim ntawv.

c. Perforation: Lub rhuab steel billet yog perforated rau hauv ib lub raj dawb paug los ntawm lub tshuab perforation, uas yog, ib tug preliminary tsim steel yeeb nkab.

d. Cov yeeb nkab dov: Lub raj khoob yog dov ntau zaus kom txo nws txoj kab uas hla, ua kom nws cov phab ntsa tuab, thiab tshem tawm cov kev ntxhov siab sab hauv.

e. Sizing: Cov yeeb nkab steel yog thaum kawg zoo li lub tshuab sizing kom txoj kab uas hla thiab phab ntsa tuab ntawm cov yeeb nkab steel ua tau raws li tus qauv yuav tsum tau ua.

f. Txias: Cov yeeb nkab zoo li cov yeeb nkab yog txias kom nws cov tawv tawv thiab lub zog.

g. Straightening: Ncaj cov yeeb nkab steel txias kom tshem tawm nws txoj kev khoov deformation.

h. Kev soj ntsuam zoo: Ua kev soj ntsuam zoo ntawm cov kav hlau tiav, suav nrog kev tshuaj xyuas qhov loj, phab ntsa thickness, hardness, nto zoo, thiab lwm yam.

3. Kev tsim cov txheej txheem ntawm seamless steel yeeb nkab #Seamless Steel Yeeb Nkab#

3. Kev tsim cov txheej txheem ntawm seamless steel yeeb nkab #Seamless Steel Yeeb Nkab#

Cov txheej txheem tshwj xeeb ntawm kev tsim seamless steel kav yog raws li hauv qab no:

a. Npaj cov ntaub ntawv raw: Xaiv cov hlau uas tsim nyog, uas yuav tsum tsis muaj qhov tsis xws luag, tsis muaj npuas, thiab tsis muaj kab nrib pleb ntawm qhov chaw.

b. Cua sov: Cua sov cov hlau billet mus rau lub xeev kub siab, qhov cua kub cua sov yog 1000-1200 ℃.

c. Perforation: Lub rhuab steel billet yog perforated rau hauv lub raj dawb paug los ntawm lub tshuab tho. Lub sijhawm no, lub raj khoob tseem tsis tau ua tiav.

d. Cov yeeb nkab dov: Lub raj tsis muaj xa mus rau cov yeeb nkab dov tshuab rau ntau qhov rollings kom txo tau txoj kab uas hla ntawm lub raj thiab ua kom cov phab ntsa tuab, thaum tshem tawm cov kev ntxhov siab sab hauv.

e. Reheating: Rov ua dua lub dov lub raj dawb kom tshem tawm nws cov kev ntxhov siab sab hauv.

f. Sizing: Cov yeeb nkab steel yog thaum kawg zoo li lub tshuab sizing kom txoj kab uas hla thiab phab ntsa tuab ntawm cov yeeb nkab steel ua tau raws li tus qauv yuav tsum tau ua.

g. Txias: Txias cov yeeb nkab steel, feem ntau yog siv dej txias lossis cua txias.

h. Straightening: Ncaj cov yeeb nkab steel txias kom tshem tawm nws txoj kev khoov deformation.

i. Kev soj ntsuam zoo: Ua kev soj ntsuam zoo ntawm cov kav hlau tiav, suav nrog kev tshuaj xyuas qhov loj, phab ntsa thickness, hardness, nto zoo, thiab lwm yam.

Thaum lub sij hawm tsim khoom, cov ntsiab lus hauv qab no yuav tsum tau muab sau tseg: ua ntej, qhov zoo thiab ruaj khov ntawm cov khoom siv raw yuav tsum tau ua kom ntseeg tau; thib ob, qhov kub thiab siab yuav tsum tau tswj nruj me ntsis thaum lub sij hawm tho thiab dov txheej txheem kom tsis txhob tawg thiab deformation; Thaum kawg, sizing thiab txias Lub stability thiab ncaj ntawm cov yeeb nkab steel yuav tsum tau khaws cia thaum lub sij hawm txheej txheem.

4. Kev tswj xyuas zoo ntawm seamless steel kav

Txhawm rau kom ntseeg tau tias qhov zoo ntawm seamless steel kav, cov hauv qab no yuav tsum tau tswj:

a. Cov ntaub ntawv nyoos: Siv cov ntawv hlau zoo nkauj kom ntseeg tau tias tsis muaj qhov tsis xws luag, npuas, lossis tawg ntawm qhov chaw. Nyob rau tib lub sijhawm, nws yog ib qho tsim nyog los xyuas kom meej tias cov tshuaj muaj pes tsawg leeg thiab cov khoom siv ntawm cov khoom siv raw khoom raws li tus qauv yuav tsum tau ua.

b. Cov txheej txheem ntau lawm: nruj me ntsis tswj txhua tus txheej txheem hauv cov txheej txheem tsim khoom kom ntseeg tau tias qhov zoo ntawm txhua tus txheej txheem yog ruaj khov thiab txhim khu kev qha. Tshwj xeeb tshaj yog thaum lub sij hawm tho thiab dov txheej txheem, kub thiab siab yuav tsum tau nruj me ntsis tswj kom tsis txhob tawg thiab deformation.

c. Dimensions: Ua qhov ntsuas qhov ntev ntawm cov kav hlau ua tiav kom ntseeg tau tias lawv txoj kab uas hla thiab phab ntsa tuab ua tau raws li cov qauv xav tau. Kev ntsuas tshwj xeeb tuaj yeem siv rau kev ntsuas, xws li micrometers, phab ntsa thickness ntsuas ntsuas, thiab lwm yam.

d. Qhov zoo ntawm qhov chaw: Ua qhov kev tshuaj ntsuam xyuas zoo ntawm cov kav hlau ua tiav, suav nrog qhov chaw roughness, muaj cov kab nrib pleb, folding thiab lwm yam tsis xws luag. Kev kuaj xyuas tuaj yeem ua tiav nrog kev tshuaj xyuas qhov muag lossis cov cuab yeej kuaj tshwj xeeb.

e. Metallographic qauv: Ua cov qauv metallographic kuaj ntawm cov yeeb nkab steel tiav kom ntseeg tau tias nws cov qauv metallographic ua tau raws li tus qauv yuav tsum tau ua. Feem ntau, lub tshuab kuaj kab mob yog siv los soj ntsuam cov qauv metallographic thiab xyuas seb puas muaj cov kab mob microscopic.

f. Cov khoom siv kho tshuab: Cov khoom siv hluav taws xob ntawm cov kav hlau tiav tau raug sim, suav nrog hardness, tensile lub zog, yield zog thiab lwm yam ntsuas. Tensile kuaj tshuab thiab lwm yam khoom siv tuaj yeem siv rau kev sim.

Los ntawm cov kev tswj xyuas zoo saum toj no, qhov zoo ntawm seamless steel kav tuaj yeem ua kom ruaj khov thiab txhim khu kev qha, ua tau raws li qhov xav tau ntawm ntau daim ntawv thov.

5. Daim ntawv thov cheeb tsam ntawm seamless steel kav

Seamless steel kav muaj ntau yam kev siv, feem ntau suav nrog cov hauv qab no:

a. Kev lag luam roj av: siv hauv cov kav dej roj, cov kav dej thiab cov kav dej tshuaj hauv cov roj av. Seamless steel kav muaj cov yam ntxwv ntawm lub zog siab, corrosion kuj, thiab kub tsis kam, thiab tuaj yeem ua kom muaj kev nyab xeeb thiab ruaj khov ntawm kev lag luam roj av.

b. Kev lag luam tshuaj: Hauv kev lag luam chemical, seamless steel kav yog dav siv nyob rau hauv ntau yam tshuaj tiv thaiv pipelines, kua thauj pipelines, thiab lwm yam. Vim nws muaj zog corrosion kuj, nws muaj peev xwm tiv taus qhov yaig ntawm ntau yam tshuaj lom neeg, ua kom muaj kev ruaj ntseg thiab kev ua haujlwm ntawm kev lag luam tshuaj.

Seamless steel yeeb nkab yog ib puag ncig steel nrog lub hollow seem thiab tsis muaj seams nyob ib ncig ntawm nws. Nws muaj cov yam ntxwv ntawm lub zog siab, corrosion kuj, siab kub thiab kub tsis kam. Raws li cov txheej txheem kev tsim khoom sib txawv, cov kav dej seamless steel tuaj yeem muab faib ua ob hom: cov kav dej kub dov thiab cov kav dej txias. Cov kav dej kub dov yog tsim los ntawm cov cua sov steel billets ntawm qhov kub thiab txias rau perforation, dov, txias thiab lwm yam txheej txheem, thiab tsim nyog rau cov kav hlau loj thiab nyuaj; Cov kav dej txias txias yog tsim los ntawm txias dov ntawm chav tsev kub thiab tsim nyog rau kev tsim khoom me me hla ntu thiab siab dua precision steel kav.

Post lub sij hawm: Nov-28-2023