15Mo3 (15MoG): Nws yog cov yeeb nkab steel hauv DIN17175 tus qauv. Nws yog ib txoj kab me me carbon molybdenum steel raj rau boiler thiab superheater, thiab pearlescent hom kub lub zog hlau. Hauv xyoo 1995, nws tau hloov mus rauGB5310thiab npe 15MoG. Nws cov tshuaj muaj pes tsawg leeg yog qhov yooj yim, tab sis nws muaj molybdenum, yog li nws muaj lub zog thermal zoo dua li carbon steel thaum tswj cov txheej txheem kev ua tau zoo ib yam li carbon steel. Vim nws qhov kev ua tau zoo, tus nqi pheej yig, tau siv dav hauv ntiaj teb. Txawm li cas los xij, cov hlau muaj kev nyiam rau graphitization tom qab kev ua haujlwm ntev ntawm qhov kub siab, yog li nws qhov kev khiav hauj lwm kub yuav tsum tau tswj qis dua 510 ℃, thiab cov nqi ntawm Al ntxiv hauv smelting yuav tsum txwv kom tswj thiab ncua cov txheej txheem graphitization. Lub raj steel no tsuas yog siv rau qhov kub thiab txias superheater thiab tsis kub reheater. Phab ntsa kub yog qis dua 510 ℃. Nws cov tshuaj muaj pes tsawg leeg C0.12-0.20, SI0.10-0.35, MN0.40-0.80, S≤0.035, P≤0.035, MO0.25-0.35; Lub zog ib txwm muaj σs≥270-285, σb≥450-600 MPa; Yas delta 22 lossis siab dua.

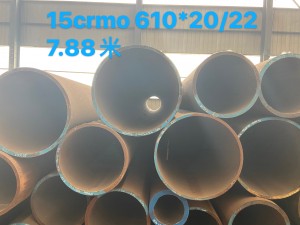

15CrMoG:GB5310-95 steel (xws li 1CR-1/2Mo thiab 11/4CR-1/2MO-Si steel dav siv nyob rau hauv lub ntiaj teb no), nws cov ntsiab lus chromium siab dua 12CrMo steel, yog li nws muaj thermal zog ntau dua ntawm 500-550 ℃. Thaum qhov kub siab tshaj 550 ℃, lub thermal zog ntawm cov hlau txo qis heev. Thaum nws ua haujlwm rau lub sijhawm ntev ntawm 500-550 ℃, graphitization tsis tshwm sim, tab sis carbide spheroidization thiab alloying ntsiab redistribution tshwm sim, uas ua rau txo qis thermal zog ntawm cov hlau. Cov hlau muaj kev tiv thaiv zoo rau kev so ntawm 450 ℃. Nws cov yeeb nkab ua thiab vuam txheej txheem kev ua tau zoo. Nws yog tsuas yog siv los ua lub siab thiab nruab nrab siab chav conduit thiab coupling lub thawv nrog chav ntsuas hauv qab 550 ℃, superheater raj nrog phab ntsa kub hauv qab 560 ℃, thiab lwm yam. Nws cov tshuaj muaj pes tsawg leeg C0.12-0.18, Si0.17-0.37, MN0.40-0.70, S≤0.030, 0.030, P≤ 0.10. MO0.40-0.55; Nyob rau hauv ib txwm tempering, lub zog theem σs≥235, σb≥440-640 MPa; Yas delta p 21.

T22 (P22), 12Cr2MoG: T22 (P22) yogASME SA213 (SIB 335) cov ntaub ntawv code, uas muaj nyob rau hauvGB5310-95. Nyob rau hauv CR-Mo steel series, nws thermal zog kev ua tau zoo kuj yog siab, tib lub zog ruaj khov thiab tso cai rau kev ntxhov siab tshaj 9CR-1Mo steel txawm siab dua, yog li nws yog dav siv nyob rau hauv txawv teb chaws thermal zog, nuclear zog thiab siab hlab ntsha. Txawm li cas los xij, nws cov kev lag luam kev lag luam tsis zoo rau peb 12Cr1MoV, yog li nws tsis tshua siv hauv kev tsim hluav taws xob hauv tsev thermal boiler. Siv tsuas yog thaum xav tau (tshwj xeeb yog thaum tsim thiab tsim ua raws li ASME code). Cov hlau tsis hnov tsw rau kev kho cua sov thiab muaj cov yas ruaj khov thiab zoo vuam kev ua haujlwm. T22 me me txoj kab uas hla raj feem ntau yog siv raws li cov hlau phab ntsa kub hauv qab 580 ℃ superheater thiab reheater cua sov nto raj, thiab lwm yam.,P22loj txoj kab uas hla yog siv nyob rau hauv cov hlau phab ntsa kub tsis ntau tshaj 565 ℃ superheater / reheater coupling lub thawv thiab lub ntsiab chav yeeb nkab. Nws cov tshuaj muaj pes tsawg leeg C≤0.15, Si≤0.50, MN0.30-0.60, S≤0.025, P≤0.025, CR1.90-2.60, MO0.87-1.13; Nyob rau hauv ib txwm tempering, lub zog theem σs≥280, σb≥450-600 MPa; Yas delta 20 lossis ntau dua.

12Cr1MoVG:GB5310-95 nano standard steel, yog lub tsev siab siab, ultra siab siab, subcritical fais fab nroj tsuag boiler superheater, sau lub thawv thiab lub ntsiab chav conduit dav siv hlau. Cov tshuaj muaj pes tsawg leeg thiab txhua yam khoom ntawm 12Cr1MoV phaj yog qhov pib zoo ib yam. Nws cov tshuaj muaj pes tsawg leeg yog yooj yim, tag nrho cov ntsiab lus alloy yog tsawg dua 2%, rau cov pa roj carbon tsawg, tsis tshua muaj alloy pearlescent hom kub lub zog hlau. Vanadium tuaj yeem tsim cov carbide VC ruaj khov nrog cov pa roj carbon, uas tuaj yeem ua rau chromium thiab molybdenum nyob rau hauv cov hlau nyiam muaj nyob hauv ferrite, thiab txo qis kev hloov pauv ntawm chromium thiab molybdenum los ntawm ferrite mus rau carbide, kom cov hlau ruaj khov ntawm qhov kub thiab txias. Tag nrho cov ntsiab lus ntawm cov hlau alloyed hauv cov hlau no tsuas yog ib nrab ntawm 2.25 CR-1Mo steel dav siv txawv teb chaws, tab sis lub zog ruaj khov ntawm 580 ℃ thiab 100,000 h yog 40% siab dua qhov tom kawg. Ntxiv mus, cov txheej txheem ntau lawm yog qhov yooj yim thiab kev ua haujlwm vuam zoo. Ntev npaum li cov txheej txheem kev kho cua sov yog nruj, qhov kev ua tau zoo thiab thermal zog ua tau zoo tuaj yeem txaus siab. Kev ua haujlwm tiag tiag ntawm lub chaw nres tsheb fais fab qhia tau hais tias 12Cr1MoV lub kav dej tseem ceeb tseem tuaj yeem siv tau tom qab kev ua haujlwm nyab xeeb ntawm 540 ℃ rau 100,000 teev. Txoj kab uas hla loj yog siv los ua lub thawv ntim khoom thiab cov kav dej tseem ceeb ntawm cov chav ntsuas hauv qab 565 ℃, thiab cov raj me me yog siv rau lub rhaub dej kub ntawm cov hlau phab ntsa kub hauv qab 580 ℃.

12Cr2MoWVTiB (G102):wb 5310-95 nyob rau hauv cov hlau, rau Tuam Tshoj tus kheej txoj kev loj hlob nyob rau hauv lub 1960s, tsis tshua muaj carbon, tsis tshua muaj alloy (me me ntawm ntau haiv neeg) Bainite hom kub zog steel, los ntawm 1970s tau suav nrog hauv Ministry of Metallurgical Industry standard YB529-70 thiab tam sim no lub teb chaws tus qauv, thaum kawg ntawm 1980 cov hlau los ntawm Ministry of Electrical Industry thiab Ministry of Electrical. kev txheeb xyuas. Cov hlau muaj cov khoom zoo txhua yam, thiab nws lub zog thermal thiab kev pabcuam kub siab dua li cov hlau zoo sib xws nyob txawv teb chaws, mus txog qib ntawm qee cov chromium-nickel austenitic steels ntawm 620 ℃. Qhov no yog vim hais tias cov hlau muaj ntau yam alloying ntsiab lus, thiab ntxiv rau txhim kho oxidation tsis kam ntawm cov ntsiab lus xws li Cr, Si, yog li qhov siab tshaj plaws kev pab cuam kub ncav cuag 620 ℃. Kev ua haujlwm tiag tiag ntawm qhov chaw nres tsheb fais fab qhia tau hais tias cov qauv thiab cov khoom ntawm cov yeeb nkab steel tsis hloov ntau tom qab ua haujlwm ntev. Nws yog siv los ua superheater raj thiab reheater raj rau ultra-siab parameter boiler nrog hlau kub ≤620 ℃. Nws cov tshuaj muaj pes tsawg leeg C0.08-0.15, Si0.45-0.75, MN0.45-0.65, S≤0.030, P≤0.030, CR1.60-2.10, MO0.50-0.65, V0.28-0.42, TI5.30.08-0. B0.002-0.008; Nyob rau hauv ib txwm tempering, lub zog theem σs≥345, σb≥540-735 MPa; Yas delta p 18.

Sa-213t91 (ib.335p91 ib): Hlau tooj nyob rau hauvASME SA-213(335) txheem. Yog tsim los ntawm Rubber Ridge National Laboratory ntawm Tebchaws Meskas, siv rau hauv nuclear fais fab (tseem siv tau rau lwm yam) kub compression Cheebtsam ntawm cov khoom, cov hlau yog raws li T9 (9CR-1MO) steel, nyob rau hauv qhov txwv ntawm cov ntsiab lus carbon, nruj me ntsis tswj cov ntsiab lus ntawm P thiab S thiab lwm yam residual ntsiab nyob rau tib lub sij hawm, Ib tug tshiab hom ntawm ferritic hlau yog tsim los ntawm cov hlau ferritic resistant. 0.030-0.070% N, 0.18-0.25% V thiab 0.06-0.10% Nb kom tau raws li cov kev cai ntawm cov nplej refinement. Nws yogASME SA-213kem txheem steel, uas tau hloov mus rau hauvGB5310tus qauv hauv xyoo 1995 thiab qib yog 10Cr9Mo1VNb. Cov txheej txheem thoob ntiaj teb ISO / DIS9399-2 yog teev raws li X10 CRMOVNB9-1.

Vim nws cov ntsiab lus chromium siab (9%), nws cov oxidation tsis kam, corrosion kuj, siab kub zog thiab tsis-graphitization nyiam zoo dua li cov hlau tsis tshua muaj hlau. Molybdenum (1%) feem ntau txhim kho qhov kub thiab txias zog thiab inhibits kub embrittling nyiam ntawm chromium hlau. Piv nrog T9, cov vuam thiab thermal qaug zog zog tau zoo dua qub, lub zog ruaj khov ntawm 600 ℃ yog peb zaug ntawm qhov kawg, thiab qhov zoo tshaj plaws-kub corrosion kuj ntawm T9 (9CR-1Mo) steel yog khaws cia. Piv nrog rau austenitic stainless hlau, lub expansion coefficient yog me me, thermal conductivity yog zoo, thiab muaj lub zog ruaj khov dua (xws li nrog TP304 austenitic steel piv, kom txog rau thaum muaj zog kub yog 625 ℃, sib npaug kev ntxhov siab kub yog 607 ℃). Yog li ntawd, nws muaj cov khoom siv zoo dua qub, cov qauv ruaj khov thiab cov khoom ua ntej thiab tom qab kev laus, zoo vuam thiab txheej txheem cov khoom, siab ruaj khov thiab oxidation kuj. Nws yog tsuas yog siv rau superheater thiab reheater nrog hlau kub ≤650 ℃ hauv boiler. Nws cov tshuaj muaj pes tsawg leeg C0.08-0.12, Si0.20-0.50, MN0.30-0.60, S≤0.010, P≤0.020, CR8.00-9.50, MO0.85-1.05, V0.18-0.25, Al≤0.0104, Al≤0.04, N0.03-0.07; Nyob rau hauv ib txwm tempering, lub zog theem σs≥415, σb≥585 MPa; Yas delta 20 lossis ntau dua.

Post lub sij hawm: Sep-07-2022