ASME SA-106/SA-106M-2015 Piperis carbonis

| Norma:ASTM SA106 | Mixtura An Non: Non |

| Grex Graduum: GR.A, GR.B, GR.C etc. | Applicatio: Tubus Fluidus |

| Crassitudo: 1 - 100 mm | Curatio Superficiei: Ut postulatio emptoris |

| Diameter Externus (Rotundus): 10 - 1000 mm | Ars: Calida Laminata |

| Longitudo: Longitudo fixa vel longitudo fortuita | Tractatio caloris: Recoctio/normalizatio |

| Forma Sectionis: Rotunda | Tubus Specialis: Alta Temperatura |

| Locus Originis: Sina | Usus: Constructio, Transportatio Fluidorum |

| Certificatio: ISO9001:2008 | Examen: ECT/CNV/NDT |

Tubus ferreus sine suturis ad operationem altae temperaturaeASTM A106, aptum ad altas temperaturas, late adhibetur in petroleo, industria chemica, caldariis, stationibus electricis, navibus, fabricatione machinarum, autocinetis, aviatione, aerospace, energia, geologia, constructione et industria militari aliisque industriis.

Gradus chalybis structuralis carbonis altae qualitatis: GR.A, GR.B, GR.C

| Compositio, 3 | |||

| Gradus A | Gradus B | Gradus C | |

| Carbonium, maximum | 0.25A | 0.3B | 0.35 miliarda |

| Manganum | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus, maximus | 0.035 | 0.035 | 0.035 |

| Sulphur, maximum | 0.035 | 0.035 | 0.035 |

| Silicium, min. | 0.10 | 0.10 | 0.10 |

| Chrome, maxC | 0.40 | 0.40 | 0.40 |

| Cuprum, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| Pro qualibet reductione 0.01% infra maximum carbonis specificatum, augmentum 0.06% manganesi supra maximum specificatum usque ad maximum 1.35% permittetur. | |||

| B Nisi aliter ab emptore specificatum est, pro qualibet reductione 0.01% infra maximum carbonis specificatum, augmentum 0.06% manganesi supra maximum specificatum usque ad maximum 1.65% permittetur. | |||

| C Haec quinque elementa coniuncta 1% non excedere debent. | |||

| Gradus A | Gradus B | Gradus C | ||||||

| Robur tensile, min, psi (MPa) | 48 000 (330) | LX milia (CDXV) | Septuaginta milia (485) | |||||

| Robur cessionis, min., psi(MPa) | Triginta milia (205) | XXXV milia (CCXL) | Quadraginta milia (ducenti septuaginta quinque) | |||||

| Longitudinalis | Transversum | Longitudinalis | Transversum | Longitudinalis | Transversum | |||

| Elongatio in 2 unc. (50 mm), min., % Experimenta fundamentalia elongationis minimae transversalis laminae, et pro omnibus magnitudinibus parvis in sectione plena probatis | 35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| Cum exemplar rotundum normale 2 pollicum (50 mm) longitudinis mensurae adhibetur | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Pro probationibus longitudinalibus striorum | A | A | A | |||||

| In probationibus transversalibus laminarum, pro singulis 1/32 pollicis (0.8 mm) decrementis crassitudinis parietis infra 5/16 pollicis (7.9 mm) ab elongatione minima fundamentali sequentis percentationis detrahetur. | 1.25 | 1.00 | 1.00 | |||||

| Elongatio minima in 2 unc. (50 mm) per aequationem sequentem determinabitur: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| pro unitatibus unciae-librae, et | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| pro unitatibus SI, | ||||||||

| ubi: e = minima elongatio in 2 unc. (50 mm), %, rotundata ad proximum 0.5%, A = area sectionis transversalis speciminis probationis tensionis, in pollicis quadratis (mm²), secundum diametrum exteriorem specificatam vel diametrum exteriorem nominalem specificatam vel latitudinem nominalem speciminis et crassitudinem parietis specificatam, rotundata ad proximum 0.01 pollicis quadratis (1 mm²). (Si area sic calculata aequalis est vel maior quam 0.75 pollicis quadratis (500 mm²), tunc valor 0.75 pollicis quadratis (500 mm²) adhibendus est.), et U = robur tensile specificatum, psi (MPa). | ||||||||

Praeterquam quod compositionem chemicam et proprietates mechanicas curant, probationes hydrostaticae singillatim, necnon probationes extendendi et applanandi perficiuntur. Praeterea, quaedam requisita sunt pro microstructura, magnitudine granorum, et strato decarburizationis tubi ferrei perfecti.

Facultates Suppletoriae: Mille Tonnae per Mensem pro Gradu Tubi Chalybei ASTM SA-106

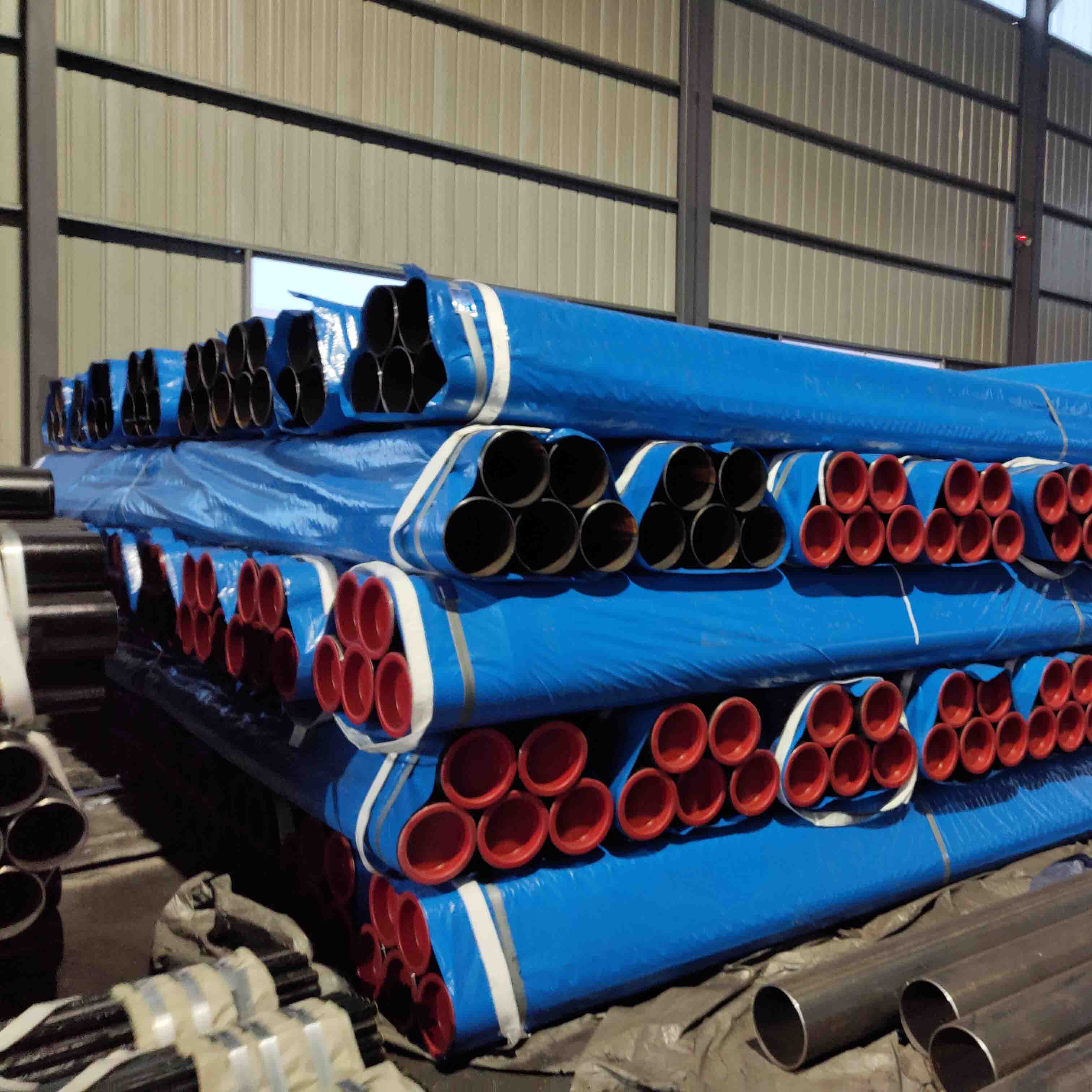

In fasciculis et in arca lignea robusta

Si in promptu est, dies VII-XIV, ad producendum dies XXX-XLV.

Depositum 30%, L/C 70% vel exemplar B/L vel L/C 100% ad conspectum