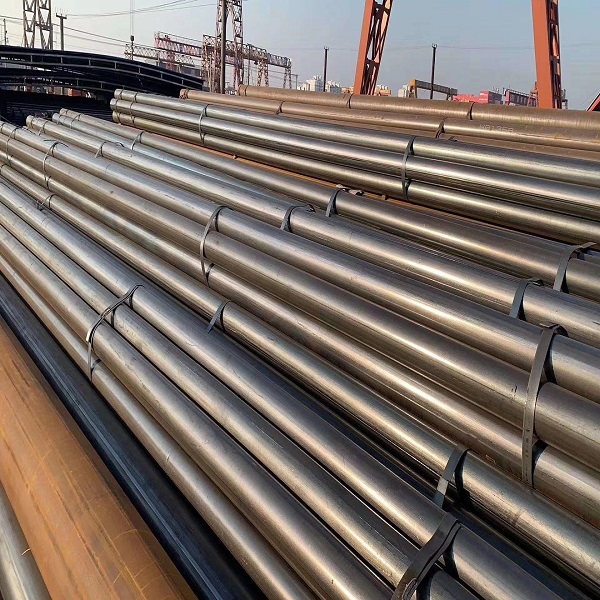

ASTM SA 213 Heat exchanger tube

| Latin:ASTM SA 213 | Admisce aut non: Alloy |

| Gradus Group: T5, T9, T11, T22 etc | Applicationem: Boiler Pipe / calor exchanger pipe |

| Crassitudo: 0.4-12.7 mm | Superficiem amet, sicut mos est scriptor postulationem |

| Diameter exterior (Round): 3.2-127 mm | Ars: Hot Rolled |

| Longitudo: certae longitudinis vel incerti longitudinis | Calor curatio: Normalising / Temperatio / Annealing |

| Figura sectionis: Circum | Specialis Pipe: Densissima Pipe Wall |

| Locus Origin: China | Usus: Super calor, boiler et caloris commutatoris |

| Certification: ISO9001:2008 | Test: ECT/UT |

Maxime adhibita est ut summus qualitas mixturam tibiam ferream ad altam pressuram boiler fistulam, caloris fistulam commutatoris et super fistulam caloris admoveret.

Gradus summus qualitas Admisce ferro: T2, T12, T11, T22, T91, T92 etc.

| Steel Gradus | Chemical Compositio% | ||||||||||

| C | Si | Mn | P, S Max | Cr | Mo | Ni Max | V | Al Max | W | B | |

| T2 | 0.10~0.20 | 0.10~0.30 | 0.30~0.61 | 0.025 | 0.50~0.81 | 0.44~0.65 | - | - | - | - | - |

| T11 | 0.05~0.15 | 0.50~1.00 | 0.30~0.60 | 0.025 | 1.00~1.50 | 0.44~0.65 | - | - | - | - | - |

| T12 | 0.05~0.15 | Max 0.5 | 0.30~0.61 | 0.025 | 0.80~1.25 | 0.44~0.65 | - | - | - | - | - |

| T22 | 0.05~0.15 | Max 0.5 | 0.30~0.60 | 0.025 | 1.90~2.60 | 0.87~1.13 | - | - | - | - | - |

| T91 | 0.07~0.14 | 0.20~0.50 | 0.30~0.60 | 0.02 | 8.0~9.5 | 0.85~1.05 | 0.4 | 0.18~0.25 | 0.014 | - | - |

| T92 | 0.07~0.13 | Max 0.5 | 0.30~0.60 | 0.02 | 8.5~9.5 | 0.30~0.60 | 0.4 | 0.15~0.25 | 0.014 | 1.50~2.00 | 0.001~0.006 |

Nam T91 praeter supra etiam Nickel 0.4, Va 0.18-0.25, Ni 0.06-0.10, Ni 0.03-0.07, Al 0.02, Ti 0.01, Zr 0.01. Maximum, nisi eminus vel minimum indicatur. Ubi ellipsis (...) in hac tabula apparent, nulla est necessitas, et analysis pro elemento determinanda vel nuntianda non est. B Licet iubere T2 et T12 contento sulphuris 0.045 max. C Vel, pro hac ratione minima, materia minimum duritiem habebit 275 HV in conditione durae, quae post austen- sionem et refrigerationem ad cella temperiem, sed ante temperantiam definitur. Duritia probatio fiet in media crassitudine producti. Duritia test frequentiae erunt duo exemplaria curatio producti per calorem multum et duritia eventus probationis in fama famae materiali referenda sunt.

| Steel Gradus | Mechanica Properties | |||

| T. S | Y. P | Prolongatio | duritia | |

| T2 | ≥ 415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) |

| T11 | ≥ 415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) |

| T12 | ≥ 415MPa | ≥ 220MPa | ≥ 30% | 163HBW(85HRB) |

| T22 | ≥ 415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) |

| T91 | ≥ 585MPa | ≥ 415MPa | ≥ 20% | 250HBW(25HRB) |

| T92 | ≥ 620MPa | ≥ 440MPa | ≥ 20% | 250HBW(25HRB) |

Licet Variationes in Wall crassitudine

| Wallthickess% | |||||

| extra diametri in. mm | 0.093 2.4 et sub | over0.095 ad 0.15 2.4-3.8 incl. | supra 0.15 ad 0.18 3.8-4.6 incl | super 0.18 " ad 4.6 " | |

| per sub supra per sub per under | |||||

| inconsutilem, calidum complevit | |||||

| 4inch et sub 40 0 35 0 33 0 28 0 | |||||

| super 4 inch .. .. 35 0 33 0 28 0 | |||||

| inconsutilem, frigus complevit | |||||

| supra sub | |||||

| 11/2 et infra | 20 0 | ||||

| super 11/2 | 22 0 | ||||

Variationes in parietibus licet crassitudines ad tubum solum applicant, praeter fistulas internas perturbatas involutum vel frigidum confectum

ante swaging, augere, inflectere, polire vel alias operationes fingere

Licet Variationes extra Diameter

| extra diametrum -mm) | Pemitted Variation (mm) | |

| calidum perfecta inconsutilem tube | super " | sub- |

| 4" (100mm) et sub | 0.4 | 0.8 |

| 4-71/2"(100-200mm) | 0.4 | 1.2 |

| 71/2-9"(200-225) | 0.4 | 1.6 |

| Conflatae sunt fistulae et frigore confecto seamless fistulae | ||

| under1"(25mm) | 0.1 | 0.11 |

| 1-11/2"(25-40mm) | 0.15 | 0.15 |

| 11/2-2"(40-50mm) | 0.2 | 0.2 |

| 2-21/2"(50-65mm) | 0.25 | 0.25 |

| 21/2-3" (65-75mm) | 0.3 | 0.3 |

| 3-4"(75-100mm) | 0.38 | 0.38 |

| 4-71/2"(100-200mm) | 0.38 | 0.64 |

| 71/2-9"(200-225) | 0.38 | 1.14 |

Hydraustatic Test:

The Steel Pipe should be tested Hydraulically One by One. Maximum Test Pressio est XX MPa. Sub Testi Impetus, Stabilitas Tempus Non Minus quam X S, Et Ferro Pipe non Leak. Vel Hydraulic Test restitui potest per Eddy Current Testis vel Magnetic Flux Leakage Testis.

Test nondestructive

Fistulae quod plus requirant inspiciendum ultrasonically inspiciendum est per unum. Post Negotiationem requirit consensum partium et specificatur in contractu, alia probatio non perniciosa addi potest.

Test adulatione

Fistulae exteriori diametro maior quam XXII Mm subicietur adulationi Test. Nulla visibiles Delaminatio, maculae albae, aut immunditie fieri debent Per totum experimentum.

Duritia Test:

Fistula Graduum P91, P92, P122, et P911, Brinell, Vickers, Vel Rockwell durities Testimoniorum erit in Specimine Loth.