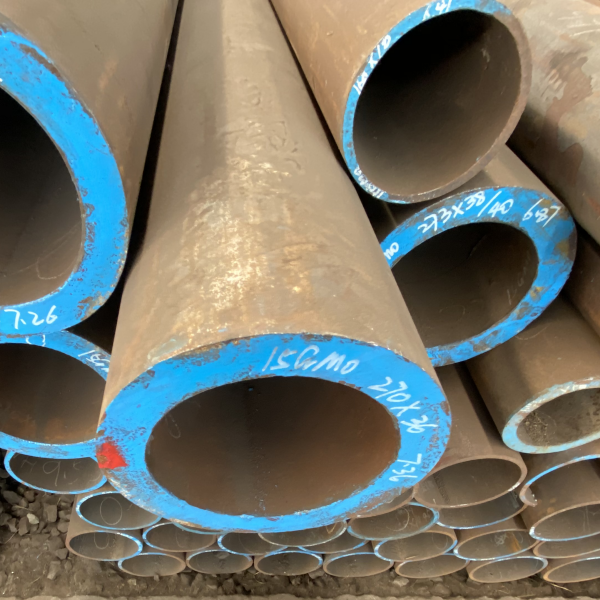

Seamless Steel tube For Petroleum Cracking, GB9948-2006

| Latin:GB9948-2006 | Calor curatio: Annealing / normalizing / Tempering |

| Grade Group: 10、12CrMo、15CrMo, 07Crl9Nil0, etc | Diameter exterior (Round): 10 - 1000 Mm |

| Crassitudo: 1 - 100 mm | Applicationem: calor commutationem fistulae |

| Diameter exterior (Round): 10 - 1000 mm | Superficiem amet, ut Customer opus est |

| Longitudo, certae longitudinis vel incerti longitudinis | Ars: Hot Rolled |

| Sectio Figura: Circum | Specialis Pipe: Densissima Pipe Wall |

| Locus Origin: China | Usus: calor commutationem fistulae |

| Certification: ISO9001:2008 | Test: UT/MT |

Tubus ferri inconsutilem pro petroleum crepuit, inconsutilem tubulam ferream pro tubulis fornacibus, caloris fistulae permutationis et fistulae pressionis in industria petrochemical.

Princeps qualitas structuralis chalybis carbonis gradus sunt 20g, 20mng et 25mng.

Admisceri structurae ferri gradus: 15mog, 20mog, 12crmog

15CrMoG、12Cr2MoG、12CrMoVG, etc

Gradus summus qualitas carbo carbonis structuralis ferro: 10#.20#

Qualitas carbo carbonis structilis princeps gradus gradus: 20g, 20mng et 25mng

Admisceri structurae ferri gradus: 15mog, 20mog, 12crmog, 15CrMoG、12Cr2MoG, etc.

| No | Gradus | Chemical Component % | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| High Quality Carbon Structural Steel | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| Admisce Structural Ferro | 12CrMo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 |

| 15CrMo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12CrlMo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | |

| 12CrlMoV | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0.024 | 0. 010 | |

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | ||

| 12Cr5MoNT | |||||||||||||

| 12Cr9MoI | <0.15 | 0. XXV-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| 12Cr9MoNT | |||||||||||||

| Aliquam calor resistens Steel | 07Crl9Nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 |

| 07Crl8NillNb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | |

| 07Crl9NillTi | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00~13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0. 015 | |

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | |

| No | Tensile MPa | Cede MPa | Post fracturam A/% | Horrendum effusio industria kv2/j | Brinell duritia numero | ||

| effigies | transver | effigies | transver | ||||

| non minus quam | non magis quam | ||||||

| 10 | 335〜475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410〜550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410〜560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440〜640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415〜560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470〜640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450~600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415〜590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoNT | 480〜640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460〜640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9MoNT | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9NilO | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | >520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | >520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | >485 | 170 | 35 | 一 | - | 187 HBW | |

| Nam chalybea parietis crassitudine minor quam 5mm tubo experimentum duritiem non faciunt | |||||||

HYDRAULICUS test

Expertus hydraulicus pro ferro tibiis singillatim peragendis. Maxime test pressio XX MPa est. Sub pressione experimenti, tempus stabilizationis non minus quam 10 s erit, et lacus ferreae fistulae non permittitur.

test adulatione

Experimentum adulationis agetur pro fistula ferrea cum diametro exteriore major quam 22 mm

Flaring test

Princeps qualitas chalybis carbonis structuralis et incorrupta (calor-repugnans) fistulae ferreae cum diametro exteriore non plus 76 mm et parietis crassitie non plus quam 8 mm sub experimento dilatandi erit. Expertus flagrans in cella temperies exercebitur. Diameter exterior ratis specimen elatans post summum nucleum cereum 60% of flaminium occurret requisitis mensae 7. Nulla rimas vel rimas in specimen post urentem concessum est. Secundum exigentias postulatoris et in contractu notatis, stannum structurale ferrum etiam adhiberi potest ad probationem dilatationem.

Nondestructive teste

Fistulae ferreae vitio detectioni ultrasonicae subicientur singillatim secundum praescripta GB / T 5777-2008. Secundum exigentias postulatoris, aliae probationes non perniciales addi possunt post tractatum inter supplementum et postulatorem et in contractu indicatis.

Erugo test

Testa corrosio intergranuaria agetur ad fistulam chalybem immaculatam (calor repugnans). Methodus probandi erit secundum praescripta methodi Sinensis E in GB/T 4334-2008, et corrosio intergranulare proclivitas post experimentum non licet.

Post tractatum inter supplicem et postulatorem, et notatis in contractu, postulator potest alias methodos testium corrosionis designare.

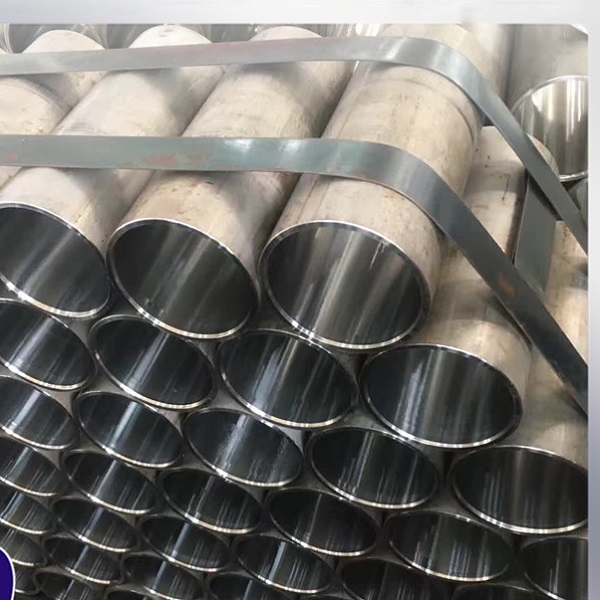

Oleum petrochemicum, pressura alta boiler, usus specialis tubo inconsutilem boiler inconsutilem, tubo geologico seamless ferro tubo et tubo olei inconsutilem.

Chemical Component

| notam | Chemical Component(%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb+Ta | S | P | |

| 15CrMo | 0.12~0.18 | 0.40~0.70 | 0.17~0.37 | 0.80~1.10 | 0.40~0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Mechanica Property

| notam | Tensile MPa | Cede MPa | Prolongatio% |

| 15CrMo | 440~640 | 295 | 22 |