SA213 ityhubhu yebhoyila yoxinzelelo oluphezuluuthotho yi aityhubhu yebhoyila yoxinzelelo oluphezuluuthotho. Ifanele iityhubhu zentsimbi ezingenamthungo kunye ne-austenitic enobunzima obuncinane bodonga lwebhoyila kunye nezifudumezi eziphezulu kunye neetyhubhu zentsimbi ezishushu zokutshintsha ubushushu.

Imibhobho yomphezulu wokufudumeza esetyenziswa kwiibhoyila zoxinzelelo oluphantsi naphakathi (uxinzelelo olusebenzayo alukho mkhulu kune-5.88Mpa, ubushushu obusebenzayo bungaphantsi kwama-450 ℃); isetyenziswa kwiibhoyila zoxinzelelo oluphezulu (uxinzelelo olusebenzayo luhlala lungaphezulu kwe-9.8Mpa, ubushushu obusebenzayo buphakathi kwe-450℃~650℃)) iityhubhu zomphezulu wokufudumeza, ii-superheaters, izifudumezi, iityhubhu zeshishini lepetrochemical, njl.

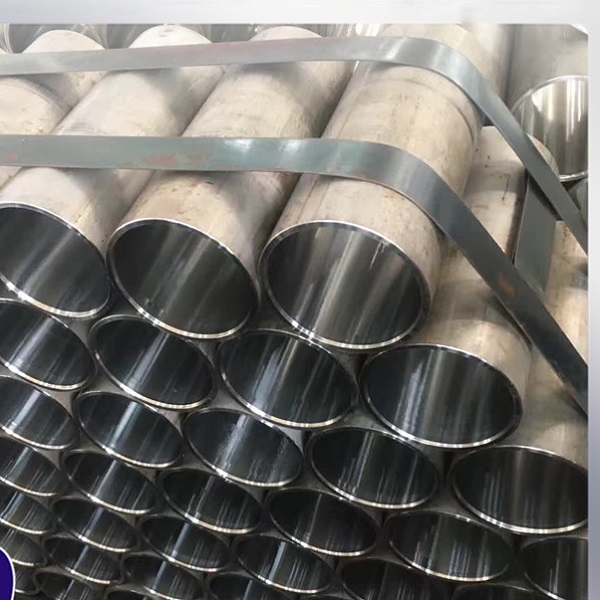

I-ASME SA213 T12umbhobho wentsimbi ye-alloy, inkokeli kwimibhobho yensimbi engenamthungo yaseMelika, isetyenziswa kakhulu kwipetroleum, kushishino lweekhemikhali, amandla ombane kunye namanye amasimi oshishino. Olu hlobo lombhobho wensimbi lwenziwe ngentsimbi ephezulu. Emva kokucutshungulwa ngononophelo kwiinkqubo ezininzi, inamandla aphezulu kunye nokumelana nokugqwala okuphezulu. Inokuhlangabezana neemfuno zokusetyenziswa kwiindawo ezahlukeneyo ezinzima.

Inkqubo yayo yokuvelisa iyinkimbinkimbi kwaye intle, kubandakanywa ukunyibilika, ukuqengqeleka, ukubhoboza, umzobo obandayo, unyango lobushushu kunye nezinye izixhumanisi. Ngethuba lokwenziwa kwenkqubo yokuvelisa, umbhobho wensimbi ufumana ukuxilongwa kweempazamo ezininzi kunye novavanyo olungonakalisi ukuqinisekisa umgangatho obalaseleyo kunye nokuthembeka. Kukho kwakhona uhlalutyo lweekhemikhali ezahlukeneyo, uhlalutyo lwe-metallographic kunye nezinye iimvavanyo zokuqinisekisa ukuba ukubunjwa kwayo, ukwakhiwa kombutho, ukusebenza kunye nezinye izikhombisi zihlangabezana neemfuno eziqhelekileyo.

Iimpawu zeI-ASME SA213 T12umbhobho wentsimbi ingxubevange ngolu hlobo lulandelayo:

1. Amandla aphezulu: Inamandla aphezulu okuqina kunye nenqaku lesivuno, kwaye inokumelana nemithwalo emikhulu kunye neempembelelo.

2. Ukumelana ne-corrosion ephezulu: Inokumelana ne-corrosion enamandla kwiindawo ezahlukeneyo eziyinkimbinkimbi, ezifana ne-acids, i-alkalis, i-salts kunye nezinye izinto zeekhemikhali kunye neendawo ezigqithisileyo ezifana nokushisa okuphezulu kunye nokushisa okuphantsi.

3. Ukusebenza kakuhle kwe-welding: Yenziwe ngentsimbi ephezulu, ayinakukwazi ukuqhekeka, iipores kunye nezinye iingxaki ngexesha le-welding, ukuqinisekisa umgangatho we-welding kunye nokuthembeka.

4. Uluhlu olubanzi lwezicelo: Isetyenziswe ngokubanzi kwi-petroleum, imboni yeekhemikhali, amandla ombane kunye nezinye iindawo zoshishino, ezifana neepayipi ze-oyile kunye negesi, i-boilers, i-reactors kunye nezinye izixhobo.

Ixesha lokuposa: Nov-29-2023