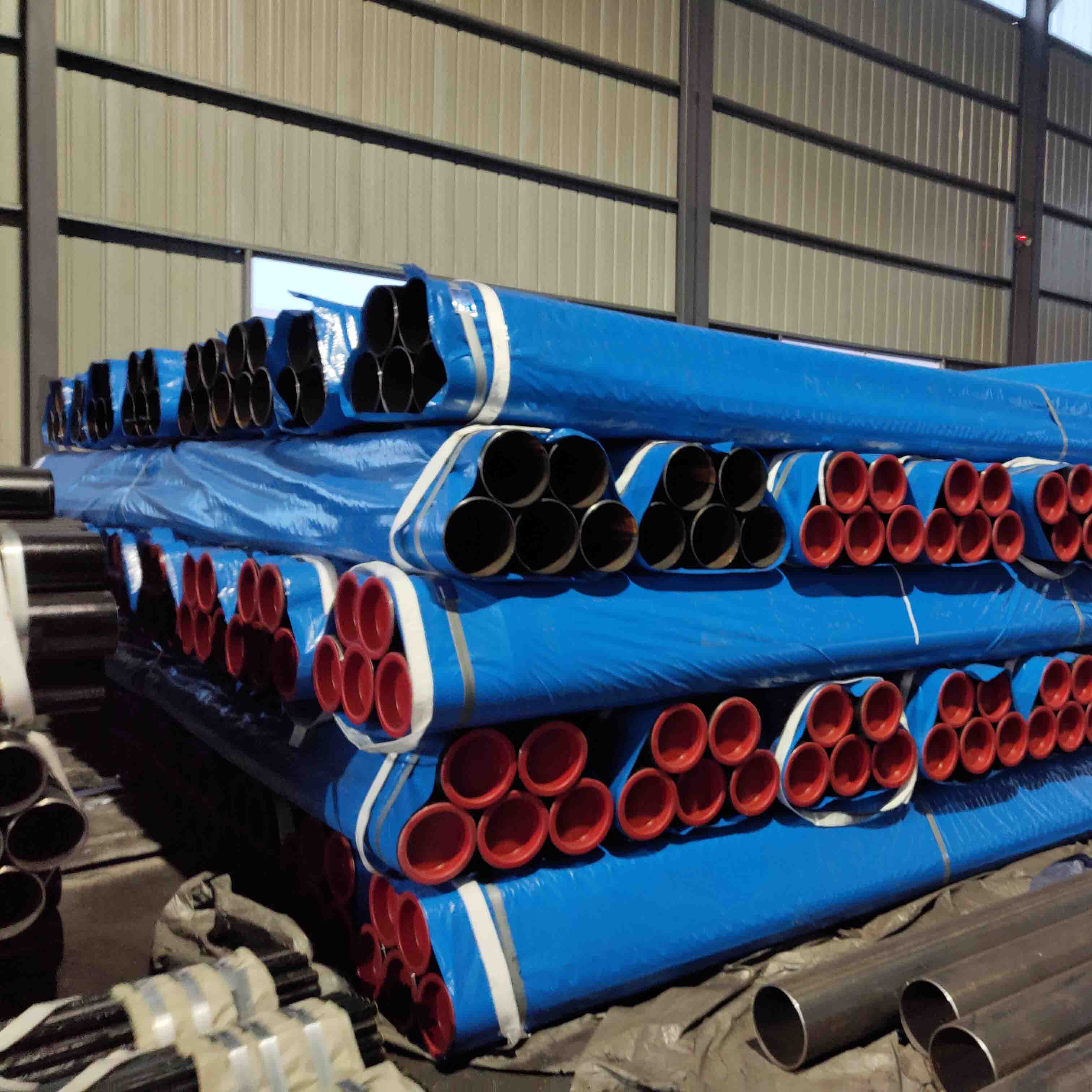

ASME SA-106/SA-106M-2015 Umbhobho wentsimbi yeCarbon

| Umgangatho:I-ASTM SA106 | Ingxubevange okanye Hayi: Hayi |

| IQela leBakala: G.A,GR.B,GR.C njl | Isicelo: Fluid Pipe |

| Ukutyeba: 1 - 100 mm | Unyango loMphezulu: Njengemfuno yomthengi |

| I-Diameter yangaphandle (Round): 10 - 1000 mm | Ubuchwephesha: I-Hot Rolled |

| Ubude: Ubude obuzinzileyo okanye ubude obungenamkhethe | Unyango lobushushu: Ukuphelisa/ukwenza oko kuqhelekileyo |

| Ubume beCandelo: Round | Umbhobho okhethekileyo: Ubushushu obuphezulu |

| Indawo yemvelaphi: eTshayina | Usetyenziso: Ulwakhiwo, uThutho lolwelo |

| Isiqinisekiso: ISO9001:2008 | Uvavanyo: ECT/CNV/NDT |

Umbhobho wentsimbi ongenamthungo wokusebenza kobushushu obuphezuluI-ASTM A106, ilungele ubushushu obuphezulu, isetyenziswa kakhulu kwipetroleum, kwishishini lekhemikhali, kwibhoyila, kwisikhululo samandla, iinqanawa, ukwenziwa koomatshini, iimoto, iinqwelomoya, i-aerospace, amandla, ijoloji, ulwakhiwo kunye neshishini lomkhosi kunye namanye amashishini.

IBanga lentsimbi yolwakhiwo lwekhabhoni ekumgangatho ophezulu: G.A,GR.B,GR.C

| Uqulunqo, % | |||

| IBanga A | IBanga B | IBanga C | |

| Ikhabhoni, max | 0.25A | 0.3B | 0.35B |

| IManganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus, max | 0.035 | 0.035 | 0.035 |

| Isulfure, max | 0.035 | 0.035 | 0.035 |

| Isilicon, min | 0.10 | 0.10 | 0.10 |

| IChrome, maxC | 0.40 | 0.40 | 0.40 |

| Ubhedu, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| A Ngokucuthwa ngakunye nge-0.01% ngaphantsi kobuninzi bekhabhoni echaziweyo, ukonyuka kwe-0.06% yemanganese ngaphezu kowona mlinganiselo uphezulu uchaziweyo kuya kuvunyelwa ukuya kuthi ga kwi-1.35 ubuninzi. | |||

| B Ngaphandle kokuba kucaciswe ngolunye uhlobo ngumthengi, kunciphiso ngalunye lwe-0.01% ngaphantsi kobuninzi bekhabhoni obuchaziweyo, ukwanda kwe-0.06% yemanganese ngaphezu kobuninzi obuchaziweyo kuya kuvunyelwa ukuya kutsho kubuninzi be-1.65%. | |||

| C Ezi zinto zintlanu zidibene aziyi kuba ngaphezu kwe-1%. | |||

| IBanga A | IBanga B | IBanga C | ||||||

| Amandla okuqina, min, psi(MPa) | 48 000(330) | 60 000(415) | 70 000(485) | |||||

| Amandla esivuno, min, psi(MPa) | 30 000(205) | 35 000(240) | 40 000(275) | |||||

| Ixesha elide | Ukunqamleza | Ixesha elide | Ukunqamleza | Ixesha elide | Ukunqamleza | |||

| Elongation kwi-2 ngo. (50 mm), min, % Ubuncinane bobude obunqamlezileyo bovavanyo lwemicu, kunye nabo bonke oosayizi abancinci bavavanywa kwicandelo elipheleleyo | 35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| Xa umgangatho umjikelo 2-ngaphakathi. (50-mm) isampuli yovavanyo lobude begeyiji iyasetyenziswa | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Kwiimvavanyo ze-longitudinal strip | A | A | A | |||||

| Kuvavanyo lomcu onqamlezileyo, ukutsalwa kwe-1/32-in nganye. (0.8-mm) ukuhla kobunzima bodonga ngaphantsi kwe-5/16 ngo. | 1.25 | 1.00 | 1.00 | |||||

| A Ubuncinane bobude kwi-2 in. (50 mm) buya kumiselwa ngolunxaki lulandelayo: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| iiyunithi intshi-phawundi, kwaye | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| kwiiyunithi ze-SI, | ||||||||

| apho: e = ubude obuncinane kwi-2 in. (50 mm), %, isondezwe kwi-0.5% ekufutshane, A = indawo enqamlezileyo yomzekelo wovavanyo loxinzelelo, kwi-.2 (mm2), ngokusekelwe kwidayamitha ecacisiweyo yangaphandle okanye idiyamitha echaziweyo yangaphandle okanye ububanzi besampulu yesiqhelo kunye nobukhulu bodonga obuchaziweyo, ijikelezwe kweyona kufutshane 0.01 in.2 (1 mm2). (Ukuba ummandla obalwa ngolu hlobo ulingana okanye ungaphezulu kwe-0.75 kwi-2 (500 mm2), ngoko ixabiso elingu-0.75 kwi-2 (500 mm2) liya kusetyenziswa.), kunye U = amandla okuqina achaziweyo, i-psi (MPa). | ||||||||

Ukongeza ekuqinisekiseni ukubunjwa kweekhemikhali kunye neempawu zemishini, iimvavanyo ze-hydrostatic zenziwa nganye nganye, kwaye iimvavanyo ze-flaring kunye ne-flattening ziyenziwa. . Ukongezelela, kukho iimfuno ezithile ze-microstructure, ubukhulu bengqolowa, kunye ne-decarburization layer yombhobho wensimbi ogqityiweyo.

Ubunakho bokubonelela: iiToni ezili-1000 ngenyanga ngeBanga ngalinye le-ASTM SA-106

Kwimiyanda kunye nakwiBhokisi yoMthi eyomeleleyo

7-14 iintsuku ukuba isitokhwe, 30-45 iintsuku ukuvelisa

30% idepsoit, 70% L/C okanye B/L ikopi okanye 100% L/C ngokubona