ASME SA-106/SA-106M-2015 Dhuumaha birta kaarboon

| Heerka:ASTM SA106 | Alloy Mise: Maya |

| Kooxda Fasalka: GR.A,GR.B,GR.C iwm | Codsiga: Dhuumaha dareeraha ah |

| Dhumucda: 1 - 100 mm | Daaweynta Dusha sare: Sida looga baahan yahay macmiilka |

| Dhexroorka (wareega): 10 - 1000 mm | Farsamada: Hot Rolled |

| Dhererka: Dhererka go'an ama dhererka random | Daaweynta kulaylka: Annealing/caadaynta |

| Qaabka Qaybta: Wareeg | Dhuumaha Gaarka ah: Heerkulka sare |

| Meesha Asal ahaan: Shiinaha | Isticmaalka: Dhismaha, Gaadiidka dareeraha ah |

| Shahaadada: ISO9001:2008 | Imtixaan: ECT/CNV/NDT |

Dhuumaha birta ah ee aan fiicnayn ee hawlgalka heerkulka sareASTM A106, ku haboon heerkulka sare, Waxaa si weyn loo isticmaalaa in batroolka, warshadaha kiimikada, kuleyliyaha, saldhigga korontada, markabka, wax soo saarka mishiinka, baabuurta, duulista, hawada, tamarta, geology, dhismaha iyo warshadaha military iyo warshadaha kale.

Fasalka birta qaab dhismeedka tayada sare leh: GR.A,GR.B,GR.C

| Halabuurka, % | |||

| Darajada A | Darajada B | Darajada C | |

| Kaarboon, max | 0.25A | 0.3B | 0.35B |

| Manganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Fosfooraska, max | 0.035 | 0.035 | 0.035 |

| Sulfur, max | 0.035 | 0.035 | 0.035 |

| Silikoon, min | 0.10 | 0.10 | 0.10 |

| Chrome, maxC | 0.40 | 0.40 | 0.40 |

| Copper, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| A Dhimista 0.01% ee ka hoosaysa ugu badnaan kaarboonka la cayimay, korodhka 0.06% manganese ee ka sarreeya inta la cayimay waxa la ogolaan doonaa ugu badnaan 1.35%. | |||

| B Ilaa si kale u qeexo iibsaduhu, hoos u dhac kasta oo ah 0.01% ee ka hooseeya ugu badnaan kaarboonka la cayimay, korodhka 0.06% manganese ee ka sarreeya inta la cayimay waxa la ogolaan doonaa ugu badnaan 1.65%. | |||

| C Shantan walxood oo la isku daray waa in aanay ka badnayn 1%. | |||

| Darajada A | Darajada B | Darajada C | ||||||

| Xoog xajin, min, psi(MPa) | 48 000 (330) | 60 000 (415) | 70 000 (485) | |||||

| Awood soo saar, min, psi(MPa) | 30 000 (205) | 35 000 (240) | 40 000 (275) | |||||

| Dheeraad ah | Guddoon | Dheeraad ah | Guddoon | Dheeraad ah | Guddoon | |||

| Kordhinta 2 inji (50 mm), min, % Tijaabooyin xariijin transverse ugu yar ee aasaasiga ah, iyo dhammaan cabbirrada yaryar oo lagu tijaabiyay qayb buuxda | 35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| Marka heerka wareega 2-in. (50-mm) muunadada dhererka cabbirka ayaa la isticmaalaa | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Imtixaannada xariijimaha dhaadheer | A | A | A | |||||

| Tijaabooyinka xariijinta leexsan, laga jarayo 1/32-in kasta. (0.8-mm) hoos u dhaca dhumucda gidaarka ee ka hooseeya 5/16 inch | 1.25 | 1.00 | 1.00 | |||||

| A Dhererka ugu yar ee 2 inji (50 mm) waa in lagu go'aamiyaa isla'egta soo socota: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| ee cutubyada inch-pound, iyo | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| ee cutubyada SI, | ||||||||

| meesha: e = dhererka ugu yar ee 2 inji (50 mm), %, lagu soo koobay 0.5% ugu dhow, A = aagga isdhaafka ah ee muunada tijaabada xiisadda, in.2 (mm2), oo ku salaysan dhexroor ka baxsan oo cayiman ama magac ahaan la cayimay dhexroor ka baxsan ama ballac muunada magaca iyo dhumucda gidaarka ee cayiman, oo lagu soo koobay 0.01 in.2 (1 mm2). (Haddii aagga sidaas loo xisaabiyay uu la mid yahay ama ka weyn yahay 0.75 in.2 (500 mm2), markaas waa in la isticmaalaa qiimaha 0.75 in.2 (500 mm2). U = xoogga xajinta oo cayiman, psi (MPa). | ||||||||

Marka lagu daro hubinta isku dhafka kiimikada iyo sifooyinka farsamada, tijaabooyinka hydrostatic ayaa la sameeyaa mid mid, waxaana la sameeyaa tijaabooyinka fidinta iyo fidinta. . Intaa waxaa dheer, waxaa jira shuruudo gaar ah oo loogu talagalay qaab-dhismeedka yar-yar, cabbirka hadhuudhka, iyo lakabka decarburization ee tuubada birta ee dhammaatay.

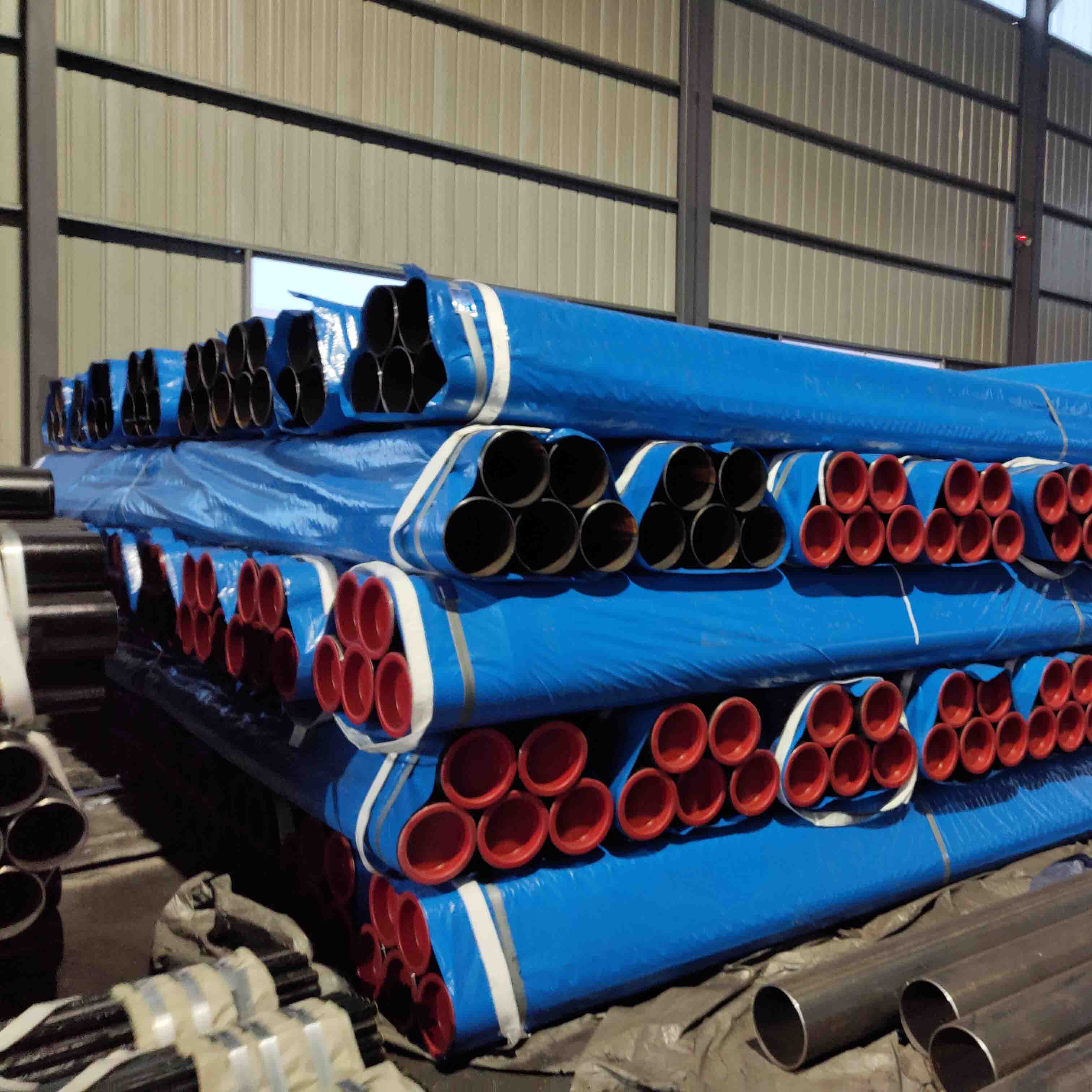

Awooda Sahayda: 1000 Tan bishii Fasalka ASTM SA-106 Dhuumaha Bir

Xirmooyinka iyo Sanduuqa Alwaaxda ee Xoogan

7-14 maalmood haddii kaydka, 30-45 maalmood si loo soo saaro

30% depsoit, 70% L/C ama nuqul B/L ama 100% L/C marka la eego