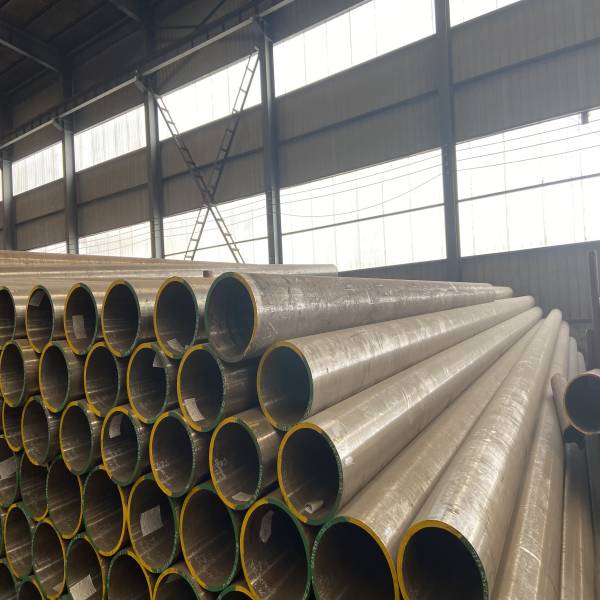

Dhuumaha birta birta ah ee aan xuduud lahayn ASTM A335 tuubada kululeeyaha cadaadiska sare

| Heerka:ASTM A335 | Alloy Mise: Alloy |

| Kooxda Fasalka: P5,P9,P11,P22,P91,P92 IWM. | Codsiga: Dhuumaha kululeeyaha |

| Dhumucda: 1 - 100 mm | Daaweynta Dusha sare: Sida Shuruudaha Macmiilka |

| Dhexroorka Dibadda (wareega): 10 - 1000 mm | Farsamada: Kulul Duubtay/ Qabow Sawiran |

| Dhererka: Dhererka go'an ama Dhererka random | Daawaynta kulaylka: Annealing/Caadimiye/Xanuujin |

| Qaabka Qaybta: Wareeg | Dhuumaha Gaarka ah: Dhuumaha gidaarka ee dhumucsan |

| Goobta Asal ahaan: Shiinaha | Isticmaalka: Dhuumaha Uumiga Cadaadiska Sarreeya, Kuleyliyaha iyo Kulaylka Bedelka |

| Shahaadada: ISO9001:2008 | Imtixaan: ET/UT |

Inta badan waxaa loo isticmaalaa in lagu sameeyo tuubo kululeeyaha oo tayo sare leh, tuubada kulaylka beddelan, tuubada uumiga cadaadis sare ee batroolka iyo warshadaha kiimikada

Fasalka tuubada aluminium tayo sare leh: P5, P9, P11, P22, P91, P92 iwm

| Darajo | UN | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| Sequiv. | ||||||||

| P1 | K11522 | 0.10-0.20 | 0.30-0.80 | 0.025 | 0.025 | 0.10-0.50 | - | 0.44 ~ 0.65 |

| P2 | K11547 | 0.10-0.20 | 0.30-0.61 | 0.025 | 0.025 | 0.10-0.30 | 0.50-0.81 | 0.44 ~ 0.65 |

| P5 | K41545 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 4.00 ~ 6.00 | 0.44 ~ 0.65 |

| P5b | K51545 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.00 ~ 2.00 | 4.00 ~ 6.00 | 0.44 ~ 0.65 |

| P5c | K41245 | 0.12 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 4.00 ~ 6.00 | 0.44 ~ 0.65 |

| P9 | S50400 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 ~ 1.00 | 8.00-10.00 | 0.44 ~ 0.65 |

| P11 | K11597 | 0.05-0.15 | 0.30-0.61 | 0.025 | 0.025 | 0.50 ~ 1.00 | 1.00 ~ 1.50 | 0.44 ~ 0.65 |

| P12 | K11562 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 0.80 ~ 1.25 | 0.44 ~ 0.65 |

| P15 | K11578 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.15 ~ 1.65 | - | 0.44 ~ 0.65 |

| P21 | K31545 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 2.65 ~ 3.35 | 0.80 ~ 1.60 |

| P22 | K21590 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 1.90 ~ 2.60 | 0.87 ~ 1.13 |

| P91 | K91560 | 0.08-0.12 | 0.30-0.60 | 0.02 | 0.01 | 0.20-0.50 | 8.00-9.50 | 0.85 ~ 1.05 |

| P92 | K92460 | 0.07-0.13 | 0.30-0.60 | 0.02 | 0.01 | 0.5 | 8.50-9.50 | 0.30-0.60 |

Magacaabid cusub oo la sameeyay si waafaqsan Practice E527 iyo SAE J1086. B Grade P 5c waa in uu lahaadaa maaddo titanium oo aan ka yarayn 4 jeer kaarboonka oo aan ka badnayn 0.70 %; ama ka kooban kolumbium 8 ilaa 10 jeer ka kooban kaarboonka.

| Guryaha makaanikada | P1,P2 | P12 | P23 | P91 | P92,P11 | P122 |

| Xoog xajin | 380 | 415 | 510 | 585 | 620 | 620 |

| Xoog soo saar | 205 | 220 | 400 | 415 | 440 | 400 |

| Darajo | Nooca Daawaynta Kulaylka | Caadiyan Xadka Heerkulka F [C] | Hoos-u-dhigid ama xanaaq |

| P5, P9, P11, iyo P22 | Qiyaasta Heerkulka F [C] | ||

| A335 P5 (b,c) | Anneal buuxa ama Isothermal | ||

| Caadiye oo xanaaq | ****** | 1250 [675] | |

| Anneal Subcritical (P5c kaliya) | ****** | 1325 - 1375 [715 - 745] | |

| A335 P9 | Anneal buuxa ama Isothermal | ||

| Caadiye oo xanaaq | ****** | 1250 [675] | |

| A335 P11 | Anneal buuxa ama Isothermal | ||

| Caadiye oo xanaaq | ****** | 1200 [650] | |

| A335 P22 | Anneal buuxa ama Isothermal | ||

| Caadiye oo xanaaq | ****** | 1250 [675] | |

| A335 P91 | Caadiye oo xanaaq | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Demisay iyo xanaaq | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

Tuubbada lagu dalbado dhexroorka gudaha, dhexroorka guduhu waa in aanu ka duwanayn wax ka badan 6 1% marka loo eego dhexroorka la cayimay

Kala duwanaanshaha la ogol yahay ee dhexroorka ka baxsan

| Naqshadeeye NPS | in | mm | in | mm |

| 1⁄8 ilaa 11⁄2, oo ay ku jiraan | 1⁄64 (0.015) | 0.4 | 1⁄64 (0.015) | 0.4 |

| In ka badan 11⁄2 ilaa 4, oo ay ku jiraan. | 1⁄32 (0.031) | 0.79 | 1⁄32 (0.031) | 0.79 |

| In ka badan 4 ilaa 8, oo ay ku jiraan | 1⁄16 (0.062) | 1.59 | 1⁄32 (0.031) | 0.79 |

| In ka badan 8 ilaa 12, oo ay ku jiraan. | 3⁄32 (0.093) | 2.38 | 1⁄32 (0.031) | 0.79 |

| In ka badan 12 | 6 1% ee la cayimay bannaanka dhexroorka |

Tijaabada Biyo-baxa:

Dhuumaha Birta waa in si Hydraul ahaan ah mid mid loo tijaabiyaa. Cadaadiska Imtixaanka ugu badan waa 20 MPa. Cadaadiska Tijaabada, wakhtiga xasilinta waa in aanu ka yarayn 10 S, tuubada birta ahna waa in aanay daadan.

Ka dib markii Isticmaaluhu ogolaado, Tijaabada Haydarooliga waxa lagu bedeli karaa Tijaabada Eddy Iminka ama Tijaabada Faleeska magnetic.

Tijaabada aan burburin:

Tuubooyinka u baahan baadhis dheeraad ah waa in si Ultrasonically ah mid mid loo baaro. Ka dib wada xaajoodku wuxuu u baahan yahay ogolaanshaha xisbiga oo lagu qeexay heshiiska, imtixaan kale oo aan burburin ayaa lagu dari karaa.

Tijaabada fidsan:

Tuubooyinka leh dhexroorka bannaanka ee ka weyn 22 mm ayaa la marsiin doonaa imtixaan fidsan. Ma jiro kala-bax muuqda, baro cad, ama wasakh ah oo ah inay dhacaan inta lagu jiro tijaabada oo dhan.

Imtixaan Adag:

Tuubooyinka Fasalada P91, P92, P122, iyo P911, Brinell, Vickers, ama Rockwell imtixaanada adkaanta waa in lagu sameeyaa muunad kasta

Tijaabada laablaab:

Tuubbada dhexroorkeedu ka sarreeyo NPS 25 oo dhexroorkeeda ilaa dhumucda gidaarka ay tahay 7.0 ama ka yar waa in la mariyaa tijaabada qaloocisa beddelka tijaabada fidsan. Tuubooyin kale oo dhexroorkoodu la mid yahay ama ka badan yahay NPS 10 ayaa laga yaabaa in la siiyo tijaabada foorarsiga beddelka tijaabadu iyadoo ay ku xidhan tahay oggolaanshaha iibsadaha.

Tuubada kululeeyaha

ASTM A335 P5waa bir daawaha ah oo aan tol lahayn tuubo heerkul sare oo Maraykan ah. Tuubbada Alloy waa nooc ka mid ah tuubada birta ah ee birta ah, waxqabadkeedu aad ayuu uga sarreeyaa tuubada birta guud ee birta ah, sababtoo ah nooca noocaan ah wuxuu ka kooban yahay C badan, waxqabadku wuu ka yar yahay tuubada birta ee caadiga ah, sidaas darteed tuubada daawaha waxaa si weyn loogu isticmaalaa batroolka, hawada hawada, kiimikada, tamarta korontada, kuleyliyaha, militariga iyo warshadaha kale.

Alloy Steel tuubooyinka waxaa ku jira tiro badan oo walxo aan ahayn kaarboon sida nikkel, chromium, silicon, manganese, tungsten, molybdenum, vanadium iyo xaddi xaddidan oo ah walxo kale oo la aqbali karo sida manganese, baaruud, silikoon, iyo fosfooraska.

Birta daawaha gudaha ee u dhiganta: 1Cr5Mo GB 9948-2006 "Heerka tuubada birta ah ee aan kala go'a lahayn ee dildilaaca batroolka"

- Lacag-bixinta: 30% Debaajiga, 70% L/C ama nuqul B/L ah ama 100% L/C Marka la eego

- Min. Tirada Dalabka:1 PC

- Awoodda Sahayda: Sannadlaha 20000 Tan ee Tubta Birta ah

- Waqtiga Hogaaminta: 7-14 Maalmood Haddi Kaydka Yahay, 30-45 Maalmood La Soo Saaro

- Xirmooyinka: Burburka Madow, Bevel iyo Koofida Tubo kasta oo kali ah; OD Ka hooseeya 219mm wuxuu u baahan yahay in lagu xidho xidhmo, xidhmo walbana kama dhaafo 2 tan.

Dulmar

| Heerka:ASTM A335 | Alloy Mise: Alloy |

| Kooxda Fasalka: P5 | Codsiga: Dhuumaha kululeeyaha |

| Dhumucda: 1 - 100 mm | Daaweynta Dusha sare: Sida Shuruudaha Macmiilka |

| Dhexroorka Dibadda (wareega): 10 - 1000 mm | Farsamada: Kulul Duubtay/ Qabow Sawiran |

| Dhererka: Dhererka go'an ama Dhererka random | Daawaynta kulaylka: Annealing/Caadimiye/Xanuujin |

| Qaabka Qaybta: Wareeg | Dhuumaha Gaarka ah: Dhuumaha gidaarka ee dhumucsan |

| Goobta Asal ahaan: Shiinaha | Isticmaalka: Dhuumaha Uumiga Cadaadiska Sarreeya, Kuleyliyaha iyo Kulaylka Bedelka |

| Shahaadada: ISO9001:2008 | Imtixaan: ET/UT |

Codsiga

Waxaa inta badan loo isticmaalaa in lagu sameeyo tuubo biyo kululeeyaha ah oo tayo sare leh, tuubada kulaylka beddelantay, tuubada uumiga cadaadiska sare ee batroolka iyo warshadaha kiimikada

Qayb Kiimiko ah

| Halabuurka | Xogta |

| Magacaabista UNS | K41545 |

| Kaarboon (ugu badnaan) | 0.15 |

| Manganese | 0.30-0.60 |

| Fosfooraska (ugu badnaan) | 0.025 |

| Silikoon (ugu badnaan) | 0.50 |

| Chromium | 4.00-6.00 |

| Molybdenum | 0.45-0.65 |

| Qaybaha Kale | … |

Hantida Makaanikada

| Guryaha | Xogta |

| Xoog Jimicsiga, Min, (MPa) | 415 Mpa |

| Xoogga Wax-soosaarka, Min, (MPa) | 205 Mpa |

| Kordhinta, Min, (%), L/T | 30/20 |

Daawaynta kulaylka

| Darajo | Nooca Daawaynta Kulaylka | Caadiyan Xadka Heerkulka F [C] | Hoos-u-dhigid ama xanaaq |

| P5, P9, P11, iyo P22 | Qiyaasta Heerkulka F [C] | ||

| A335 P5 (B,C) | Anneal Buuxa ama Isgoysyada | ||

| A335 P5b | Caadiye Oo Xanaaqa | ****** | 1250 [675] |

| A335 P5c | Subcritical Anneal | ****** | 1325 - 1375 [715 - 745] |

Dulqaad

Dhuumaha Lagu Dalbaday Dhexroorka Gudihiisa, Dhexroorka Guduhu waa in aanu ka duwanayn wax ka badan ±1 % dhexroorka la cayimay

Kala duwanaanshaha la ogol yahay ee dhexroorka ka baxsan

| Naqshadeeye NPS | Dulqaad wanaagsan | dulqaad xun | ||

| In | Mm | In | Mm | |

| 1⁄8ilaa 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64 (0.015) | 0.4 |

| In ka badan 11⁄2 Ilaa 4, Incl. | 1⁄32 (0.031) | 0.79 | 1⁄32 (0.031) | 0.79 |

| In ka badan 4 ilaa 8, Incl | 1⁄16 (0.062) | 1.59 | 1⁄32 (0.031) | 0.79 |

| In ka badan 8 ilaa 12, Incl. | 3⁄32 (0.093) | 2.38 | 1⁄32 (0.031) | 0.79 |

| In ka badan 12 | ± 1 % ee la cayimay Banaanka Dhexroorka | |||

Shuruudaha Imtixaanka

Tijaabada Biyo-baxa:

Dhuumaha Birta waa in si Hydraul ahaan ah mid mid loo tijaabiyaa. Cadaadiska Imtixaanka ugu badan waa 20 MPa. Cadaadiska Tijaabada, wakhtiga xasilinta waa in aanu ka yarayn 10 S, tuubada birta ahna waa in aanay daadan.

Ka dib markii Isticmaaluhu ogolaado, Tijaabada Haydarooliga waxa lagu bedeli karaa Tijaabada Eddy Iminka ama Tijaabada Faleeska magnetic.

Tijaabada aan burburin:

Tuubooyinka u baahan baadhis dheeraad ah waa in si Ultrasonically ah mid mid loo baaro. Ka dib wada xaajoodku wuxuu u baahan yahay ogolaanshaha xisbiga oo lagu qeexay heshiiska, imtixaan kale oo aan burburin ayaa lagu dari karaa.

Tijaabada fidsan:

Tuubooyinka leh dhexroorka bannaanka ee ka weyn 22 mm ayaa la marsiin doonaa imtixaan fidsan. Ma jiro kala-bax muuqda, baro cad, ama wasakh ah oo ah inay dhacaan inta lagu jiro tijaabada oo dhan.

Imtixaan Adag:

Tubooyinka Fasalada P91, P92, P122, iyo P911, Brinell, Vickers, Ama Rockwell Tijaabooyin Adag ayaa lagu Samayn Doonaa Tusaalaha Qayb Kasta

Tijaabada laablaab:

Tuubbada dhexroorkeedu ka sarreeyo NPS 25 oo dhexroorkeedu yahay 7.0 ama ka yar ayaa lagu marin doonaa tijaabada qallooca halkii uu ka ahaan lahaa tijaabada fidsan. Dhuumaha Kale Oo Dhexroorkeedu La Simo Ama Ka Sarreeyo NPS 10 Waxa La Siin Karaa Tijaabada Qallooca Meesha Imtixaanka Filafinta iyadoo ku xidhan Oggolaanshaha Iibsadaha

Qalabka & Wax-soo-saarka

Dhuumaha waxaa laga yaabaa inay noqoto mid kulul ama qabow oo la sawiray iyadoo la raacayo daaweynta kulaylka dhamaadka ee hoos lagu xusay.

Daawaynta kulaylka

- A / N+T

- N+T/Q+T

- N+T

Tijaabooyin Farsamo oo cayiman

- Tijaabada kacsanaanta isbedbeddelka ama dhererka dheer iyo tijaabada fidsan, Tijaabada Adag, ama Tijaabada laabta

- Kuleylka walxaha lagu daaweeyay foornada nooca Dufcadaha ah, baaritaanno waa in lagu sameeyaa 5% tuubada qayb kasta oo la daweeyay. Meelo yaryar, ugu yaraan hal tuubo waa in la tijaabiyaa.

- Kuleylka maaddiga ah ee lagu daweeyay habka joogtada ah, tijaabooyin waa in lagu sameeyaa tiro ku filan oo tuubo ah si ay u noqdaan 5% ee saamiga, laakiin xaalad aan ka yarayn 2 tuubbo.

Xusuus qorka Tijaabada laablaaban:

- Tuubbada dhexroorkeedu ka sarreeyo NPS 25 oo dhexroorkeeda ilaa dhumucda gidaarka ay tahay 7.0 ama ka yar waa in la mariyaa tijaabada qaloocisa beddelka tijaabada fidsan.

- Tuubooyin kale oo dhexroorkoodu la mid yahay ama ka badan yahay NPS 10 ayaa laga yaabaa in la siiyo tijaabada laablaabta oo ku jirta booska tijaabadu iyadoo ku xidhan ogolaanshaha iibsadaha.

- Tijaabada qalooca waa in lagu fooraraa heerkulka qolka ilaa 180 iyada oo aan dillaacin bannaanka qaybta qalooca.

ASTM A335 P5Tuubooyinka birta ah ee aan kala go'a lahayn waxay ku habboon yihiin biyaha, uumiga, hydrogen, saliid dhanaan, iwm. Haddii loo isticmaalo uumiga biyaha, heerkulka ugu badan ee shaqeyntu waa 650℃; Marka loo isticmaalo dhexdhexaadinta shaqada sida saliidda dhanaan, waxay leedahay iska caabin wanaagsan oo heerkul sare leh, waxaana badanaa loo isticmaalaa xaaladaha daxalka sulfur heerkulka sare ee 288 ~ 550℃.

Habka wax soo saarka:

1. Duubista kulul (tubo bir ah oo aan fiicneyn) : tuubo wareeg ah → kuleyl → daloolin → rogo saddex rodol ah, duubid joogto ah ama extrusion

2. Sawirka qabow (rogid) tuubo bir ah oo aan fiicneyn: tuubo wareeg ah → kuleyl → dalool → ciwaanka → dib u dhigista → pickling → saliid (dajinta naxaasta)

Xaaladaha Codsiga:

Aaladaha jawiga iyo faakuumka ee lagu farsameeyo saliid cayriin baaruud sare leh,ASTM A335 P5Tuubooyinka birta ah ee aan kala go'a lahayn ayaa inta badan loo isticmaalaa tuubooyinka hoose ee hawada iyo munaaradaha faakuumka, tuubooyinka foornada ee hawada iyo foornada faakuumka, qaybaha xawaaraha sare ee xadhkaha beddelka hawada iyo saliidda faakuumka iyo dhuumaha kale ee heerkulka sare leh ee saliidda iyo dhuumaha gaasta ay ku jiraan baaruud.

Unugyada FCC,ASTM A335 P5Tuubooyinka birta ah ee bilaa-xun waxaa inta badan loo adeegsadaa slurry heerkul sarreeya, kicinta iyo dhuumaha sifaynta soo celinta, iyo sidoo kale qaar kale oo saliidda baaruudda ah iyo dhuumaha gaaska heerkulkoodu sarreeyo.

Cutubka kookaynta oo daahay,ASTM A335 P5Dhuumaha birta ah ee aan lahayn waxaa inta badan loo isticmaalaa tuubada quudinta heerkulka sare ee hoose ee munaaradda kookaha iyo saliidda heerkulka sare iyo tuubada gaaska ee sare ee munaaradda coke, tuubada foornada ee hoose ee foornada kookaha, tuubada hoose ee munaaradda fracking iyo qaar kale oo saliid heerkul sare ah iyo tuubo gaas ah oo ka kooban baaruud.

Alloy Steel tuubooyinka waxaa ku jira tiro badan oo walxo aan ahayn kaarboon sida nikkel, chromium, silicon, manganese, tungsten, molybdenum, vanadium iyo xaddi xaddidan oo ah walxo kale oo la aqbali karo sida manganese, baaruud, silikoon, iyo fosfooraska..

ASTM A335 P9 waa bir daawaha ah oo aan tol lahayn tuubo heerkul sare oo Maraykan ah. Tuubbada Alloy waa nooc ka mid ah tuubada birta ah ee birta ah, waxqabadkeedu aad ayuu uga sarreeyaa tuubada birta guud ee birta ah, sababtoo ah nooca noocaan ah wuxuu ka kooban yahay C badan, waxqabadku wuu ka yar yahay tuubada birta ee caadiga ah, sidaas darteed tuubada daawaha waxaa si weyn loogu isticmaalaa batroolka, hawada hawada, kiimikada, tamarta korontada, kuleyliyaha, militariga iyo warshadaha kale.

A335 P9waa bir u adkaysata kulaylka chromium-molybdenum aluminium heerkul sare ah oo la soo saaray si waafaqsan heerka Maraykanka. Sababtoo ah caabbinta oksaydhka aad u fiican, xoogga heerkulka sare iyo iska caabinta daxalka sulfide, waxaa si ballaaran loo isticmaalaa heerkulka sare iyo cadaadiska sare ee dhuumaha batroolka sifeynaya iyo walxaha qarxa, gaar ahaan tuubada kulaylka tooska ah ee foornada kuleylka, heerkulka dhexdhexaadka ah wuxuu gaari karaa 550 ~ 600 ℃.

Birta daawaha gudaha ee u dhiganta: 1Cr5Mo GB 9948-2006 "Heerka tuubada birta ah ee aan kala go'a lahayn ee dildilaaca batroolka"

Dulmar

| Heerka:ASTM A335 | Alloy Mise: Alloy |

| Kooxda Fasalka: P9 | Codsiga: Dhuumaha kululeeyaha |

| Dhumucda: 1 - 100 mm | Daaweynta Dusha sare: Sida Shuruudaha Macmiilka |

| Dhexroorka Dibadda (wareega): 10 - 1000 mm | Farsamada: Kulul Duubtay/ Qabow Sawiran |

| Dhererka: Dhererka go'an ama Dhererka random | Daawaynta kulaylka: Annealing/Caadimiye/Xanuujin |

| Qaabka Qaybta: Wareeg | Dhuumaha gaarka ah: Dhuumaha derbi qaro weyn |

| Goobta Asal ahaan: Shiinaha | Isticmaalka: Dhuumaha Uumiga Cadaadiska Sarreeya, Kuleyliyaha iyo Kulaylka Bedelka |

| Shahaadada: ISO9001:2008 | Imtixaan: ET/UT |

Qayb Kiimiko ah

Halabuurka kiimikaad ee tuubooyinka birta ee aan kala go 'lahayn ee dildilaaca batroolka

| ASTM A335M | C | SI | Mn | P | S | Cr | Mo |

| P9 | ≦0.15 | 0.25-1.00 | 0.30-0.60 | ≦0.025 | ≦0.025 | 8.00-10.00 | 0.90-1.10 |

Hantida Makaanikada

| Guryaha | Xogta |

| Xoog xajin, min, (MPa) | 415 Mpa |

| Xoog soo saarid, min, (MPa) | 205 Mpa |

| Kordhinta, min, (%), L/T | 14 |

| HB | 180 |

Daawaynta kulaylka

|

Darajo | Nooca Daawaynta Kulaylka | Caadiyan Xadka Heerkulka F [C] | Hoos-u-dhigid ama xanaaq |

| P5, P9, P11, iyo P22 | |||

| A335 P9 | Anneal Buuxa ama Isgoysyada | ||

| Caadiye Oo Xanaaqa | ****** | 1250 [675] |

A335 P9waxaa lagu daweyn karaa kulaylka iyadoo la nuujinayo ama caadiyeyn + hababka xanaaqa. Xawaaraha qaboojintu waa mid gaabis ah, saamaynaysa hab-socodka wax-soo-saarka, habka wax-soo-saarka waa ay adag tahay in la xakameeyo, iyo kharash badan; Sidaa darteed, wax soo saarka dhabta ah marar dhif ah ayay isticmaalaan habka daaweynta kulaylka, inta badan waxay isticmaalaan daaweynta kulaylka caadiga ah + halkii ay ka ahaan lahaayeen habka wax-soo-saarka, si loo gaaro wax soo saarka warshadaha.

A335 P9birta sababtoo ah kuma jiraan V, Nb iyo walxo kale oo microalloying ah, sidaas awgeed heerkulka caadiga ah ee ka badan A335 P91 birta ayaa ka hooseeya, 950 ~ 1050 ℃, 950 ~ 1050 ℃, qaboojiyaha 1h, habka marka caadiga ah inta badan carbide kala diri laakiin ma jirto koritaanka hadhuudh cad, laakiin heerkulka caadiga ah aad u sarreeya waa u nugul austenite hadhuudh qallafsan, 7 ℃ heerkulka adag - 7 hoos u dhigista heerkulka. wakhtiga heerkulka heerkulka waa in si habboon loo kordhiyo.

Dulqaad

Dhuumaha Lagu Dalbaday Dhexroorka Gudihiisa, Dhexroorka Guduhu waa in aanu ka duwanayn wax ka badan ±1 % dhexroorka la cayimay

Kala duwanaanshaha la ogol yahay ee dhexroorka ka baxsan

| Naqshadeeye NPS | Dulqaad wanaagsan | dulqaad xun | ||

| In | Mm | In | Mm | |

| 1⁄8ilaa 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64 (0.015) | 0.4 |

| In ka badan 11⁄2 Ilaa 4, Incl. | 1⁄32 (0.031) | 0.79 | 1⁄32 (0.031) | 0.79 |

| In ka badan 4 ilaa 8, Incl | 1⁄16 (0.062) | 1.59 | 1⁄32 (0.031) | 0.79 |

| In ka badan 8 ilaa 12, Incl. | 3⁄32 (0.093) | 2.38 | 1⁄32 (0.031) | 0.79 |

| In ka badan 12 | ± 1 % ee la cayimay | |||

Habka wax soo saarka:

A335 waxaa loogu talagalay si waafaqsan xaaladda qalabka ee birta Tianjin iyo sifooyinkaA335 P9birta P9 habka soo saarista tijaabada ee tuubada birta ah ee aan kala go 'lahayn:Foornada arc koronto samaynta birta samaynta → sifaynta sariirta → vacuum degassing → dhinta tuurista → tuubo faaruq ah → tuubo faaruq ah → tuubo kuleyl banaan → daloolin aan caadi ahayn → toosinta → ogaanshaha cilladda ultrasonic → Tijaabada hydraulic → cabbirka iyo kormeerka muuqaalka → kaydinta.

habka wax soo saarka:

| Lambarka shayga | habka wax soo saarka | Waxqabadka iyo Xakamaynta Tayada | |||

| 1 | Kulanka kormeerka ka hor | Daqiiqado kulanka | |||

| 2 | ASEA-SKF | Hagaajin ka kooban kiimiko | |||

| *Falanqaynta halabuurka kiimikada | |||||

| *kulka dhalaalay | |||||

| 3 | CCM | billet | |||

| 4 | Kormeerka alaabta ceeriin | Kormeer madhan iyo xaqiijinta tayada | |||

| *Halka muuqaalka: Dusha sare ee billet-ka waa in ay ahaataa mid ka nadiif ah cilladaha sida nabarrada, jeexjeexyada, daloolka fiiqan, dildilaaca, iwm | |||||

| 5 | Kuleylinta bannaan | Kuleylinta biilasha foornada wareegta ah | |||

| * Xakamee heerkulka kulaylka | |||||

| 6 | daloolin tuubooyinka | Ku dalooli feedh saxan hage/ hagaha | |||

| * Xakamee heerkulka markaad daloolayso | |||||

| * Xakamee cabbirka daloolinta ka dib | |||||

| 7 | Kulul duuban | Gariirada kulul ee mashiinnada tuubada ee joogtada ah | |||

| * Deji dhumucda gidaarka tuubada | |||||

| 8 | Cabbirka | Xakamee dhexroorka ka baxsan iyo cabbirrada dhumucda derbiga | |||

| * Mashiinka dhexroorka oo dhameystiran | |||||

| * Mashiinka dhumucda derbiga oo dhammaystiran | |||||

| 9 | ka kooban kiimiko | Falanqaynta ka kooban kiimikada | |||

| * Shuruudaha oggolaanshaha ee isku dhafka kiimikada. Natiijooyinka falanqaynta ka kooban kiimikaad waa in lagu diiwaangeliyaa buuga maadiga. | |||||

| 10 | Caadiyan + Xanaaqa | Daawaynta kulaylka (caadi ahaan) ayaa la sameeyaa ka dib duubid kulul. Daaweynta kulaylku waa inay fiiro gaar ah u yeelato si loo xakameeyo heerkulka iyo muddada. | |||

| Daaweynta kulaylka ka dib, sifooyinka farsamada ee alaabtu waa inay la kulmaan heerka ASTM A335 | |||||

| 11 | qaboojinta hawada | Sariirta qaboojinta tillaabo-tallaabo | |||

| 12 | miinshaar | Goosha ilaa dherer cayiman | |||

| * Xakamaynta dhererka tuubooyinka birta | |||||

| 13 | Toosin (haddii loo baahdo) | Waxay xakameysaa flatness. | |||

| Toosin ka dib, toosnaanta waa in ay ahaataa mid waafaqsan ASTM A335 | |||||

| 14 | Kormeerka iyo Ogolaanshaha | Muuqashada iyo Kormeerka Cabirka | |||

| * Dulqaadashada cabbirka birta waa in ay ahaataa mid waafaqsan ASTM A999 | |||||

| Fiiro gaar ah: Dulqaadka dhexroorka dibadda: ± 0.75% D | |||||

| * Kormeerka muuqaalka waa in mid mid loo fuliyaa iyadoo loo eegayo heerka ASTM A999 si looga fogaado dusha sare ee liita. | |||||

| 15 | ogaanshaha cillad | * Jirka oo dhan ee tuubada birta waa in si ultrasonically ah loo baaro cilladaha dhaadheer sida waafaqsan ISO9303/E213 | |||

| Baaritaanka Ultrasonic: | |||||

| 16 | Imtixaanka hantida makaanikada | (1) Tijaabada xajinta (dhererka) iyo tijaabada fidsan | |||

| Inta jeer ee kormeerka | 5%/dufcad, ugu yaraan 2 tuubbo | ||||

| Min | Max | ||||

| P9 | Xoogga Wax-soosaarka (Mpa) | 205 | |||

| xoogga xajinta (MPa) | 415 | ||||

| Dheeraynta | Marka loo eego heerka ASTM A335 | ||||

| Tijaabada fidsan | Marka loo eego heerka ASTM A999 | ||||

| (2) Imtixaan adag | |||||

| Inta jeer ee tijaabinta: waxay la mid tahay tijaabada xajinta | 1 xabbo / dufcad | ||||

| HV&HRC | ≤250HV10&≤25 HRC HV10≤250&HRC≤25 | ||||

| Fiiro gaar ah: Heerka tijaabada adag ee Vickers: ISO6507 ama ASTM E92; | |||||

| Heerka tijaabada adag ee Rockwell: ISO6508 ama ASTM E18 | |||||

| 17 | NDT | Tuubo kasta oo bir ah waa in lagu tijaabiyaa si waafaqsan shuruudaha hababka tijaabada E213, E309 ama E570. | |||

| 18 | tijaabada cadaadiska biyaha | Tijaabada Hydrostatic iyadoo loo eegayo ASTM A999, cadaadiska tijaabada | |||

| 19 | gariir | Wareegid waafaqsan labada daraf ee tuubada birta sida waafaqsan ASTM B16.25fig.3(a) | |||

| 20 | Cabbirka miisaanka iyo dhererka | * U dulqaadashada hal miisaan: -6% ~ +4%. | |||

| 21 | Heerka tuubada | Dusha sare ee tuubada birta waa in lagu buufiyaa si waafaqsan heerka ASTM A335 iyo shuruudaha macaamiisha. Waxa ku jira calaamadayntu waa sida soo socota: | |||

| "Miisaanka Dhererka TPCO ASTM A335 Cabbirrada Bisha Sannad-Bisha P9 S LT *** C *** MPa/NDE Nambarka Kulaylka Nambarka Lot nambarka Tube | |||||

| 22 | rinjiye | Dusha sare ee tuubada waxaa lagu rinjiyeeyaa si waafaqsan heerka warshadda | |||

| 23 | koofiyadda dhamaadka tuubada | **Waa inay jiraan daboolo caag ah oo ku yaal labada daraf ee tuubo kasta | |||

| 24 | liiska alaabta | * Buuga agabka waa in lagu bixiyaa si waafaqsan EN10204 3.1. ”Macaamiishu PO waa in ay ka muuqataa buuga agabka. | |||

ASTM A335 P11 waa bir daawaha ah oo aan tol lahayn tuubo heerkul sare oo Maraykan ah. Tuubbada Alloy waa nooc ka mid ah tuubada birta ah ee birta ah, waxqabadkeedu aad ayuu uga sarreeyaa tuubada birta guud ee birta ah, sababtoo ah nooca noocaan ah wuxuu ka kooban yahay C badan, waxqabadku wuu ka yar yahay tuubada birta ee caadiga ah, sidaas darteed tuubada daawaha waxaa si weyn loogu isticmaalaa batroolka, hawada hawada, kiimikada, tamarta korontada, kuleyliyaha, militariga iyo warshadaha kale.

Dulmar

| Heerka:ASTM A335 | Alloy Mise: Alloy |

| Kooxda Fasalka: P11 | Codsiga: Dhuumaha kululeeyaha |

| Dhumucda: 1 - 100 mm | Daaweynta Dusha sare: Sida Shuruudaha Macmiilka |

| Dhexroorka Dibadda (wareega): 10 - 1000 mm | Farsamada: Kulul Duubtay/ Qabow Sawiran |

| Dhererka: Dhererka go'an ama Dhererka random | Daawaynta kulaylka: Annealing/Caadimiye/Xanuujin |

| Qaabka Qaybta: Wareeg | Dhuumaha gaarka ah: Dhuumaha derbi qaro weyn |

| Goobta Asal ahaan: Shiinaha | Isticmaalka: Dhuumaha Uumiga Cadaadiska Sarreeya, Kuleyliyaha iyo Kulaylka Bedelka |

| Shahaadada: ISO9001:2008 | Imtixaan: ET/UT |

Qayb Kiimiko ah

Halabuurka kiimikaad ee tuubooyinka birta ee aan kala go 'lahayn ee dildilaaca batroolka

| C | SI | Mn | P | S | Cr | Mo | |

| P11 | 0.05-0.15 | 0.5-1.00 | 0.30-0.61 | 0.025 | 0.025 | 1.00-1.50 | 0.44-0.65 |

Hantida Makaanikada

| Guryaha | Xogta |

| Xoog xajin, min, (MPa) | 415 Mpa |

| Xoog soo saarid, min, (MPa) | 205Mpa |

Daawaynta kulaylka

|

Darajo | Nooca Daawaynta Kulaylka | Caadiyan Xadka Heerkulka F [C] | Hoos-u-dhigid ama xanaaq |

| P5, P9, P11, iyo P22 | |||

| A335 P11 | Anneal Buuxa ama Isgoysyada | ||

| Caadiye Oo Xanaaqa | ****** | 1250[650] |

Dulqaad

Dhuumaha Lagu Dalbaday Dhexroorka Gudihiisa, Dhexroorka Guduhu waa in aanu ka duwanayn wax ka badan ±1 % dhexroorka la cayimay

Kala duwanaanshaha la ogol yahay ee dhexroorka ka baxsan

| Naqshadeeye NPS | Dulqaad wanaagsan | dulqaad xun | ||

| In | Mm | In | Mm | |

| 1⁄8ilaa 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64 (0.015) | 0.4 |

| In ka badan 11⁄2 Ilaa 4, Incl. | 1⁄32 (0.031) | 0.79 | 1⁄32 (0.031) | 0.79 |

| In ka badan 4 ilaa 8, Incl | 1⁄16 (0.062) | 1.59 | 1⁄32 (0.031) | 0.79 |

| In ka badan 8 ilaa 12, Incl. | 3⁄32 (0.093) | 2.38 | 1⁄32 (0.031) | 0.79 |

| In ka badan 12 | ± 1 % ee la cayimay | |||

ASTM A335 P22waa tuubo bir daawaha ah oo aan kala go 'lahayn oo loogu talagalay isticmaalka ferritic heerkulka sare. Tuubbada Alloy waa nooc ka mid ah tuubada birta ah ee birta ah, waxqabadkeedu aad ayuu uga sarreeyaa tuubada birta guud ee birta ah, sababtoo ah nooca noocaan ah wuxuu ka kooban yahay C badan, waxqabadku wuu ka yar yahay tuubada birta ee caadiga ah, sidaas darteed tuubada daawaha waxaa si weyn loogu isticmaalaa batroolka, hawada hawada, kiimikada, tamarta korontada, kuleyliyaha, militariga iyo warshadaha kale.

Dulmar

| Heerka:ASTM A335 | Alloy Mise: Alloy |

| Kooxda Fasalka: P22 | Codsiga: Dhuumaha kululeeyaha |

| Dhumucda: 1 - 100 mm | Daaweynta Dusha sare: Sida Shuruudaha Macmiilka |

| Dhexroorka Dibadda (wareega): 10 - 1000 mm | Farsamada: Kulul Duubtay/ Qabow Sawiran |

| Dhererka: Dhererka go'an ama Dhererka random | Daawaynta kulaylka: Annealing/Caadimiye/Xanuujin |

| Qaabka Qaybta: Wareeg | Dhuumaha gaarka ah: Dhuumaha derbi qaro weyn |

| Goobta Asal ahaan: Shiinaha | Isticmaalka: Dhuumaha Uumiga Cadaadiska Sarreeya, Kuleyliyaha iyo Kulaylka Bedelka |

| Shahaadada: ISO9001:2008 | Imtixaan: ET/UT |

Qayb Kiimiko ah

Halabuurka kiimikaad ee tuubooyinka birta ee aan kala go 'lahayn ee dildilaaca batroolka

| C | SI | Mn | P | S | Cr | Mo | |

| P22 | 0.05-0.15 | 0.5 | 0.30-0.60 | 0.025 | 0.025 | 1.90-2.60 | 0.87-1.13 |

Hantida Makaanikada

| Guryaha | Xogta |

| Xoog xajin, min, (MPa) | 415 Mpa |

| Xoog soo saarid, min, (MPa) | 205Mpa |

Daawaynta kulaylka

|

Darajo | Nooca Daawaynta Kulaylka | Caadiyan Xadka Heerkulka F [C] | Hoos-u-dhigid ama xanaaq |

| P5, P9, P11, iyo P22 | |||

| A335 P22 | Anneal Buuxa ama Isgoysyada | ||

| Caadiye Oo Xanaaqa | ****** | 1250[650] |

Dulqaad

Dhuumaha Lagu Dalbaday Dhexroorka Gudihiisa, Dhexroorka Guduhu waa in aanu ka duwanayn wax ka badan ±1 % dhexroorka la cayimay

Kala duwanaanshaha la ogol yahay ee dhexroorka ka baxsan

| Naqshadeeye NPS | Dulqaad wanaagsan | dulqaad xun | ||

| In | Mm | In | Mm | |

| 1⁄8ilaa 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64 (0.015) | 0.4 |

| In ka badan 11⁄2 Ilaa 4, Incl. | 1⁄32 (0.031) | 0.79 | 1⁄32 (0.031) | 0.79 |

| In ka badan 4 ilaa 8, Incl | 1⁄16 (0.062) | 1.59 | 1⁄32 (0.031) | 0.79 |

| In ka badan 8 ilaa 12, Incl. | 3⁄32 (0.093) | 2.38 | 1⁄32 (0.031) | 0.79 |

| In ka badan 12 | ± 1 % ee la cayimay | |||

A335 P22 waa 2.25Cr-1Mo Chromium-molybdenum Heerkulka Sare ee birta kuleyliyaha iyo kuleyliyaha sare,ASTM A335/A335Mheerka. 1985kii, waxaa lagu beeray GB5310 waxaana loo bixiyay 12Cr2MoG. Wadamada kale waxay leeyihiin darajooyin bir ah oo la mid ah, sida Jamhuuriyadda Federaalka ee Jarmalka 10CrMo910 iyo Japan STBA24. Taxanaha birta ee cr-1Mo, xooggeeda kulaylku waa mid aad u sarreeya, heerkul isku mid ah (heerkulka≤580℃) xooga jabka furkiisa iyo walbahaarka la ogolyahay ayaa xitaa ka sareeya birta 9CR-1Mo, waxayna leedahay wax qabad wanaagsan oo wax qabad iyo alxanka, caag waara oo wanaagsan. Sidaa darteed, waxaa si weyn loogu isticmaalay jawi shaqo oo adag, sida tamarta kulaylka, tamarta nukliyeerka iyo qaar ka mid ah qalabka hydrogen ee tuubooyinka kuleylka kala duwan iyo maraakiibta cadaadiska sare.

Heerkulka la oggol yahay: A335P22 (SA-213T22) waxaa inta badan lagu isticmaalaa 300,600MW iyo heerkulka kale ee warshadda korontada kuleyliyaha weyn≤580℃kulaylka sare iyo tuubada heerkulka derbiga & LT;540℃tuubada uumiga gidaarka iyo madaxa, noocan oo kale ah ee birta ah ayaa si weyn loogu isticmaalay Maraykanka, Japan iyo Europe, waxay leedahay taariikh dheer oo hawlgal ah ee dhirta korontada, waa waxqabadka xasilloon, habka wanaagsan ee waxqabadka birta bislaaday.

12Cr1MoV steel waxaa iska leh chromium-molybdenum vanadium birta vanadium birta, inta badan loo isticmaalo 12Cr1MoV/GB5310 tuubooyinka birta. Si ballaaran loo isticmaalo, heerkulku waa 480℃~580℃aagga heerkulka sare oo leh mid ka mid ah qalabka ugu badan. 12Cr1MoVG heerkulka adeegga birta: waxaa inta badan loo isticmaalaa birta ugu weyn ee tuubada superheater, madaxa iyo tuubada uumiga kululeeyaha cadaadiska sare kaas oo heerkulka gidaarka tuubada uu ka yar yahay ama la mid yahay 580℃.

Habka wax soo saarka: Imtixaan adag:

1. Duubista kulul (tubo bir ah oo aan fiicneyn) : tuubo wareeg ah → kuleyl → daloolin → rogo saddex rodol ah, duubid joogto ah ama extrusion

2. Sawirka qabow (rogid) tuubo bir ah oo aan fiicneyn: tuubo wareeg ah → kuleyl → dalool → ciwaanka → dib u dhigista → pickling → saliid (dajinta naxaasta)

Baakad:

Baakad qaawan / xidhmo xidhmo / baakad sanduuq ah / ilaalinta alwaax ee labada dhinac ee tuubooyinka oo si ku habboon loo ilaaliyo u keenista qiimaha badda ama sida la codsado.

Dulmar

P92 tuubbada kululeeyaha heerkul sare ee caadiga ah ee tuubbada daawaha aan xuduud lahayn.

| Heerka:ASTM A335 | Alloy Mise: Alloy |

| Kooxda Fasalka: P92 | Codsiga: Dhuumaha kululeeyaha |

| Dhumucda: 1 - 100 mm | Daaweynta Dusha sare: Sida Shuruudaha Macmiilka |

| Dhexroorka Dibadda (wareega): 10 - 1000 mm | Farsamada: Kulul Duubtay/ Qabow Sawiran |

| Dhererka: Dhererka go'an ama Dhererka random | Daawaynta kulaylka: Annealing/Caadimiye/Xanuujin |

| Qaabka Qaybta: Wareeg | Dhuumaha gaarka ah: Dhuumaha derbi qaro weyn |

| Goobta Asal ahaan: Shiinaha | Isticmaalka: Dhuumaha Uumiga Cadaadiska Sarreeya, Kuleyliyaha iyo Kulaylka Bedelka |

| Shahaadada: ISO9001:2008 | Imtixaan: ET/UT |

Qayb Kiimiko ah

Halabuurka kiimikaad ee tuubooyinka birta ee aan kala go 'lahayn ee dildilaaca batroolka

| C | SI | Mn | P | S | Cr | Mo | |

| P92 | 0.07-0.13 | 0.5 | 0.30-0.60 | 0.02 | 0.01 | 8.50-9.5 | 0.30-0.60 |

Hantida Makaanikada

| Guryaha | Xogta |

| Xoog xajin, min, (MPa) | 620 Mpa |

| Xoog soo saarid, min, (MPa) | 440Mpa |

Daawaynta kulaylka

|

Darajo | Nooca Daawaynta Kulaylka | Caadiyan Xadka Heerkulka F [C] | Hoos-u-dhigid ama xanaaq |

| P5, P9, P11, iyo P22 | |||

| A335 P92 | Anneal Buuxa ama Isgoysyada | ||

| Caadiye Oo Xanaaqa | ****** | 1250[675] |

Dulqaad

Dhuumaha Lagu Dalbaday Dhexroorka Gudihiisa, Dhexroorka Guduhu waa in aanu ka duwanayn wax ka badan ±1 % dhexroorka la cayimay

Kala duwanaanshaha la ogol yahay ee dhexroorka ka baxsan

| Naqshadeeye NPS | Dulqaad wanaagsan | dulqaad xun | ||

| In | Mm | In | Mm | |

| 1⁄8ilaa 11⁄2, Incl | 1⁄64 (0.015) | 0.4 | 1⁄64 (0.015) | 0.4 |

| In ka badan 11⁄2 Ilaa 4, Incl. | 1⁄32 (0.031) | 0.79 | 1⁄32 (0.031) | 0.79 |

| In ka badan 4 ilaa 8, Incl | 1⁄16 (0.062) | 1.59 | 1⁄32 (0.031) | 0.79 |

| In ka badan 8 ilaa 12, Incl. | 3⁄32 (0.093) | 2.38 | 1⁄32 (0.031) | 0.79 |

| In ka badan 12 | ± 1 % ee la cayimay | |||