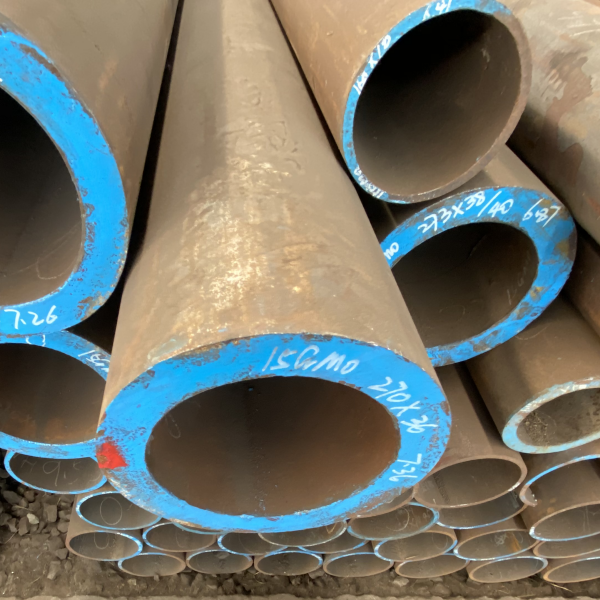

Gaadhida Degdegga ah ee 15crmog, 12crmovg Biyo-qaadista Kuleyliyaha Sare

Dadaalka ugu weyn ee lagu daboolayo baahiyaha macmiilka, dhammaan hawlgalladayada waxaa si adag loo fuliyaa si waafaqsan hal-ku-dheggeenna "High Excellent, Sicir Iibka Gardarada ah, Adeeg Degdega ah" ee Bixinta Degdegga ah ee 15crmog, 12crmovg Drain Superheat Boiler Tube, Dhammaan kharashyadu waxay ku xiran yihiin tirada ee amarkaaga; dheeraadka ah ee aad dalbato, kharashka dheeraadka ah ee dhaqaale waa. Waxaan sidoo kale bixinnaa kaalmo OEM oo wanaagsan noocyo badan oo caan ah.

Dadaalka ugu weyn ee lagu daboolayo baahida macmiilka, dhammaan hawlgalladayada waxaa si adag loo fuliyaa si waafaqsan hal-ku-dhiggeena "High Excellent, Sicir Iibka Adag, Adeeg Degdega ah"Shiinaha 15crmog Tubooyinka kululeeyaha iyo 12cr1movg Tubooyinka kululeeyaha, Waxaan had iyo jeer ku adkaysanayaa mabda'a ah "Tayada iyo adeeggu waa nolosha alaabta". Ilaa hadda, badeecadayada waxaa loo dhoofiyay in ka badan 20 wadan iyada oo hoos timaada xakamaynta tayada adag iyo adeegga heerka sare.

Dulmar

| Heerka:GB9948-2006 | Daawaynta kulaylka: Annealing/caadaynta/Xanaajinta |

| Kooxda Fasalka: 10, 12CrMo, 15CrMo, 07Crl9Nil0, iwm | Dhexroorka Dibadda (wareega): 10 - 1000 mm |

| Dhumucda: 1 - 100 mm | Codsiga: tuubooyinka isweydaarsiga kulaylka |

| Dhexroorka (wareega): 10 - 1000 mm | Daaweynta Dusha sare: Sida Shuruudaha Macmiilka |

| Dhererka: Dhererka go'an ama dhererka random | Farsamada: Hot Rolled |

| Qaabka Qaybta: Wareeg | Dhuumaha Gaarka ah: Dhuumaha gidaarka ee dhumucsan |

| Meesha Asal ahaan: Shiinaha | Isticmaalka: tuubooyinka isweydaarsiga kulaylka |

| Shahaadada: ISO9001:2008 | Imtixaan:UT/MT |

Codsiga

Tuubooyinka birta ah ee dillaaca batroolka ayaa lagu dabaqi karaa tuubooyinka birta ee tubooyinka foornada, tuubooyinka kulaylka iyo tuubooyinka cadaadiska ee warshadaha kiimikada.

Heerarka birta qaab dhismeedka tayada sare leh waa 20g, 20mng iyo 25mng.

Darajooyinka birta qaab dhismeedka Alloy: 15mog, 20mog, 12cmog

15CrMoG, 12Cr2MoG, 12CrMoVG, iwm

Fasalka ugu weyn

Fasalka birta qaab dhismeedka kaarboon ee tayada sare leh: 10#, 20#

Heerarka birta qaab dhismeedka tayada sare leh: 20g, 20mng iyo 25mng

Darajooyinka birta qaab dhismeedka Alloy: 15mog, 20mog, 12crmog, 15CrMoG, 12Cr2MoG, iwm

Qayb Kiimiko ah

| No | Darajo | Qayb kiimiko % | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| Birta Dhismaha Kaarboon Tayada Sare leh | 10 | 0. 07-0.13 | 0.17-0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17-0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| Alloy Structural Steel | 12CrMo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 |

| 15CrMo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12CrlMo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | |

| 12CrlMoV | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15-0. 30 | <0. 20 | 0.025 | 0. 010 | |

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45-0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | ||

| 12Cr5MoNT | |||||||||||||

| 12Cr9MoI | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| 12Cr9MoNT | |||||||||||||

| Birta u adkaysata kulaylka aan lahayn | 07Crl9Nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 |

| 07Crl8NillNb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | |

| 07Crl9NillTi | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00 ~ 13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0. 015 | |

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10.00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | |

Hantida Makaanikada

| Maya | Jilicsan MPa | Wax-soo-saarka MPa | Jilicsan jabka ka dib A/% | Tamar nuugista Shork kv2/j | Nambarka adag ee Brinell | ||

| sawir | wareejin | sawir | wareejin | ||||

| aan ka yarayn | aan ka badnayn | ||||||

| 10 | 335 - 475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410 - 550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410-560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440-640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415-560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470-640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450-600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415-590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoNT | 480-640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460-640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9MoNT | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9NilO | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | >520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | >520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | >485 | 170 | 35 | 一 | - | 187 HBW | |

| Birta leh dhumucdiisuna waxay ka yar tahay 5mm tuubo ha samayn tijaabo adag | |||||||

Shuruudaha Imtixaanka

Tijaabada Haydarooliga

Tijaabada Haydarooliga waa in lagu sameeyaa tuubooyinka birta mid mid. Cadaadiska ugu badan ee tijaabada waa 20 MPa. Cadaadiska tijaabada, wakhtiga xasilinta waa inuusan ka yarayn 10 s, iyo daadinta tuubada birta lama ogola.

Tijaabada fidsan

Tijaabada fidinta waa in lagu sameeyaa tuubo bir ah oo dhexroorka ka weyn tahay 22 mm

Tijaabada ololaysa

Birta qaab dhismeedka kaarboon tayo sare leh iyo tuubooyinka birta ah ee aan lahayn (kulka u adkaysta) ee leh dhexroorka dibadda oo aan ka badnayn 76 mm iyo dhumucdiisuna aanay ka badnayn 8 mm waa in lagu tijaabiyaa balaarin. Tijaabada ololka waa in lagu sameeyaa heerkulka qolka. Dhererka dhexroorka dibadda ee muunada ka dib taper xudunta sare waa 60% ee ololaysa waa in ay buuxisaa shuruudaha miiska 7. Ma jiro dildilaacyo ama dildilaaca on muunada ka dib ololaya. Marka loo eego shuruudaha dalbadaha oo lagu xusay qandaraaska, birta qaab dhismeedka alloy sidoo kale waxaa loo isticmaali karaa ballaarinta tijaabada.

xiniinyo aan burburin

Tuubooyinka birta ah waa in ay hoos yimaadaan ogaanshaha cilladda ultrasonic mid mid si waafaqsan xeerarka GB / T 5777-2008. Marka loo eego shuruudaha dalbadaha, tijaabooyin kale oo aan burburin ayaa lagu dari karaa ka dib markii ay wada xaajoodaan alaab-qeybiyaha iyo alaab-qeybiyaha oo lagu tilmaamo qandaraaska.

Baaritaanka daxalka intergranular

Tijaabada daxalka intergranular waa in lagu sameeyaa tuubooyinka birta ah ee aan lahayn (kulka u adkaysta). Habka imtixaanku waa inuu waafaqsan yahay qodobada habka Shiinaha E ee GB / T 4334-2008, iyo u janjeersiga daxalka intergranular lama ogola ka dib imtixaanka.

Ka dib markii ay wada xaajoodaan alaab-qeybiyaha iyo alaab-qeybiyaha, oo lagu xusay heshiiska, dalbadeeyuhu wuxuu magacaabi karaa hababka kale ee baaritaanka daxalka.

Faahfaahinta Alaabta

tuubooyinka farsamada/kiimikada & bacriminta

GB/T8162-2008

ASTM_A519-2006

TS EN 10210-1-2006

ASTM A53A53M-2012

GB9948-2006

GB6479-2013

GB/T 17396-2009

Dadaalka ugu weyn ee lagu daboolayo baahiyaha macmiilka, dhammaan hawlgalladayada waxaa si adag loo fuliyaa si waafaqsan hal-ku-dheggeenna "High Excellent, Sicir Iibka Gardarada ah, Adeeg Degdega ah" ee Bixinta Degdegga ah ee 15crmog, 12crmovg Drain Superheat Boiler Tube, Dhammaan kharashyadu waxay ku xiran yihiin tirada ee amarkaaga; dheeraadka ah ee aad dalbato, kharashka dheeraadka ah ee dhaqaale waa. Waxaan sidoo kale bixinnaa kaalmo OEM oo wanaagsan noocyo badan oo caan ah.

Gaadhida degdega ah ee Shiinaha 15crmog tuubooyinka kululeeyaha iyo 12crmovg tuubooyinka kululeeyaha, Waxaan had iyo jeer ku adkaysanayaa mabda'a ah "Tayada iyo adeegga waa nolosha alaabta". Ilaa hadda, badeecadayada waxaa loo dhoofiyay in ka badan 20 wadan iyada oo hoos timaada xakamaynta tayada adag iyo adeegga heerka sare.

Saliid, kiimiko kiimikaad, kuleyliyaha cadaadiska sare, isticmaalka gaarka ah ee tuubada kuleyliyaha tuubbada aan fiicneyn, tuubo bir ah oo juqraafi ah iyo tuubo saliideed ah.

Qayb Kiimiko ah

| sumadda | Qayb Kiimiko ah (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb+Ta | S | P | |

| 15CrMo | 0.12-0.18 | 0.40 ~ 0.70 | 0.17-0.37 | 0.80 ~ 1.10 | 0.40 ~ 0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Hantida Makaanikada

| sumadda | Jilicsan MPa | Wax-soo-saarka MPa | Kordhinta (%) |

| 15CrMo | 440 ~ 640 | 295 | 22 |