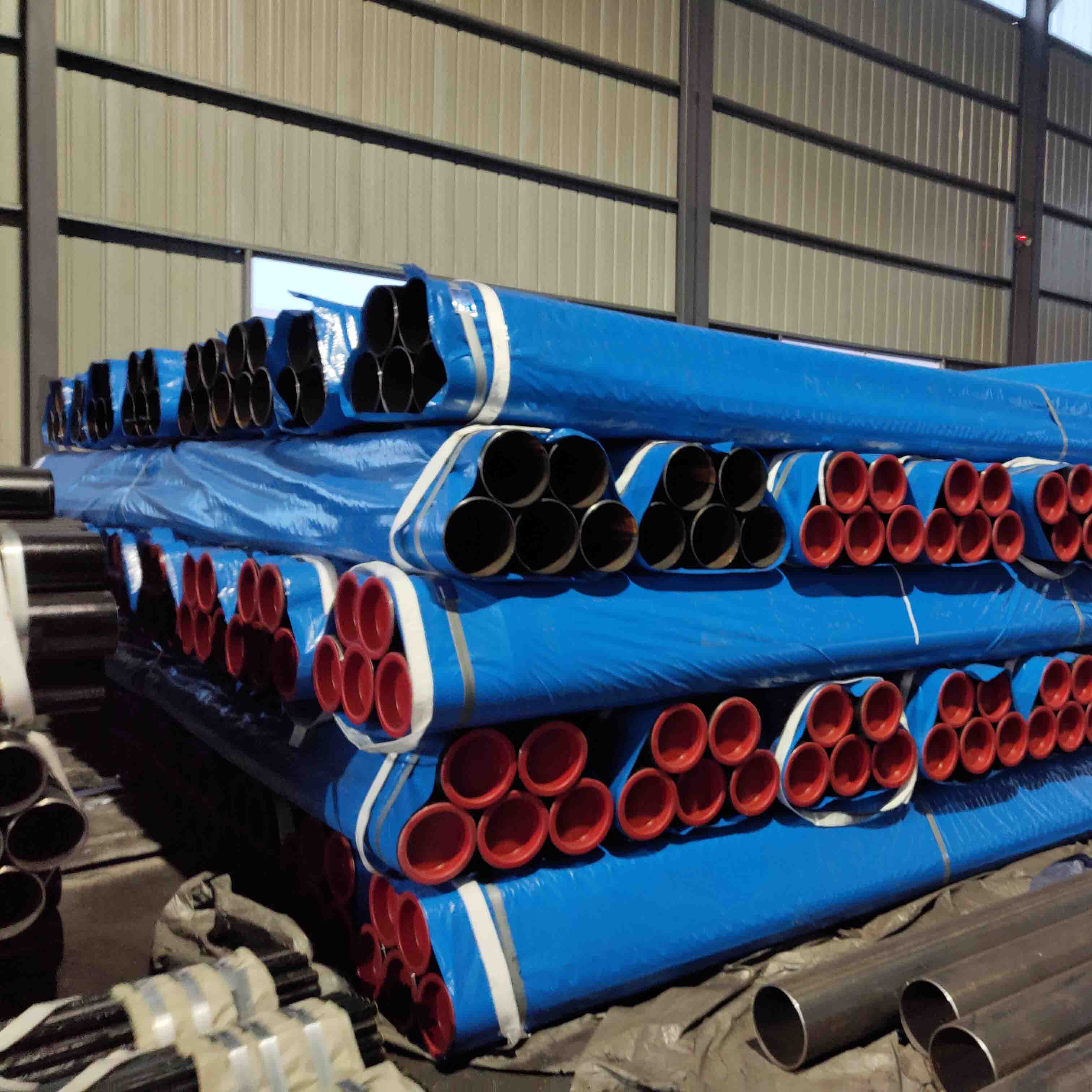

Umbhobho wentsimbi yekhabhoni

| Umgangatho:I-ASTM SA106 | Ingxubevange okanye Hayi: Hayi |

| IQela leBakala: G.A,GR.B,GR.C njl | Isicelo: Fluid Pipe |

| Ukutyeba: 1 - 100 mm | Unyango loMphezulu: Njengemfuno yomthengi |

| I-Diameter yangaphandle (Round): 10 - 1000 mm | Ubuchwephesha: I-Hot Rolled |

| Ubude: Ubude obuzinzileyo okanye ubude obungenamkhethe | Unyango lobushushu: Ukuphelisa/ukwenza oko kuqhelekileyo |

| Ubume beCandelo: Round | Umbhobho okhethekileyo: Ubushushu obuphezulu |

| Indawo yemvelaphi: eTshayina | Usetyenziso: Ulwakhiwo, uThutho lolwelo |

| Isiqinisekiso: ISO9001:2008 | Uvavanyo: ECT/CNV/NDT |

Umbhobho wentsimbi ongenamthungo wokusebenza kobushushu obuphezuluI-ASTM A106, ilungele ubushushu obuphezulu, isetyenziswa kakhulu kwipetroleum, kwishishini lekhemikhali, kwibhoyila, kwisikhululo samandla, iinqanawa, ukwenziwa koomatshini, iimoto, iinqwelomoya, i-aerospace, amandla, ijoloji, ulwakhiwo kunye neshishini lomkhosi kunye namanye amashishini.

IBanga lentsimbi yolwakhiwo lwekhabhoni ekumgangatho ophezulu: G.A,GR.B,GR.C

| Uqulunqo, % | |||

| IBanga A | IBanga B | IBanga C | |

| Ikhabhoni, max | 0.25A | 0.3B | 0.35B |

| IManganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus, max | 0.035 | 0.035 | 0.035 |

| Isulfure, max | 0.035 | 0.035 | 0.035 |

| Isilicon, min | 0.10 | 0.10 | 0.10 |

| IChrome, maxC | 0.40 | 0.40 | 0.40 |

| Ubhedu, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| A Ngokucuthwa ngakunye nge-0.01% ngaphantsi kobuninzi bekhabhoni echaziweyo, ukonyuka kwe-0.06% yemanganese ngaphezu kowona mlinganiselo uphezulu uchaziweyo kuya kuvunyelwa ukuya kuthi ga kwi-1.35 ubuninzi. | |||

| B Ngaphandle kokuba kucaciswe ngolunye uhlobo ngumthengi, kunciphiso ngalunye lwe-0.01% ngaphantsi kobuninzi bekhabhoni obuchaziweyo, ukwanda kwe-0.06% yemanganese ngaphezu kobuninzi obuchaziweyo kuya kuvunyelwa ukuya kutsho kubuninzi be-1.65%. | |||

| C Ezi zinto zintlanu zidibene aziyi kuba ngaphezu kwe-1%. | |||

| IBanga A | IBanga B | IBanga C | ||||||

| Amandla okuqina, min, psi(MPa) | 48 000(330) | 60 000(415) | 70 000(485) | |||||

| Amandla esivuno, min, psi(MPa) | 30 000(205) | 35 000(240) | 40 000(275) | |||||

| Ixesha elide | Ukunqamleza | Ixesha elide | Ukunqamleza | Ixesha elide | Ukunqamleza | |||

| Elongation kwi-2 ngo. (50 mm), min, % Ubuncinane bobude obunqamlezileyo bovavanyo lwemicu, kunye nabo bonke oosayizi abancinci bavavanywa kwicandelo elipheleleyo | 35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| Xa umgangatho umjikelo 2-in. (50-mm) isampuli yovavanyo lobude begeyiji iyasetyenziswa | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Kwiimvavanyo ze-longitudinal strip | A | A | A | |||||

| Kuvavanyo lomcu onqamlezileyo, ukutsalwa kwe-1/32-in nganye. (0.8-mm) ukuhla kobunzima bodonga ngaphantsi kwe-5/16 ngo. | 1.25 | 1.00 | 1.00 | |||||

| A Ubuncinane bobude kwi-2 in. (50 mm) buya kumiselwa ngolunxaki lulandelayo: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| iiyunithi intshi-phawundi, kwaye | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| kwiiyunithi ze-SI, | ||||||||

| apho: e = ubude obuncinane kwi-2 in. (50 mm), %, isondezwe kwi-0.5% ekufutshane, A = indawo enqamlezileyo yomzekelo wovavanyo loxinzelelo, kwi-.2 (mm2), ngokusekelwe kwidayamitha exeliweyo yangaphandle okanye idiyamitha echaziweyo engaphandle okanye ububanzi besampulu yesiqhelo kunye nobukhulu bodonga obuchaziweyo, isondezwe koyena 0.01 in.2 okufutshane (1 mm2) . (Ukuba ummandla obalwa ngolu hlobo ulingana okanye ungaphezulu kwe-0.75 kwi-2 (500 mm2), ngoko ixabiso elingu-0.75 kwi-2 (500 mm2) liya kusetyenziswa.), kunye U = amandla okuqina achaziweyo, i-psi (MPa). | ||||||||

Ukongeza ekuqinisekiseni ukubunjwa kweekhemikhali kunye neempawu zemishini, iimvavanyo ze-hydrostatic zenziwa nganye nganye, kwaye iimvavanyo ze-flaring kunye ne-flattening ziyenziwa. . Ukongezelela, kukho iimfuno ezithile ze-microstructure, ubukhulu bengqolowa, kunye ne-decarburization layer yombhobho wensimbi ogqityiweyo.

Ubunakho bokubonelela: iiToni ezili-1000 ngenyanga ngeBanga ngalinye le-ASTM SA-106

Kwimiyanda kunye nakwiBhokisi yoMthi eyomeleleyo

7-14 iintsuku ukuba isitokhwe, 30-45 iintsuku ukuvelisa

30% idepsoit, 70% L/C okanye B/L ikopi okanye 100% L/C ngokubona