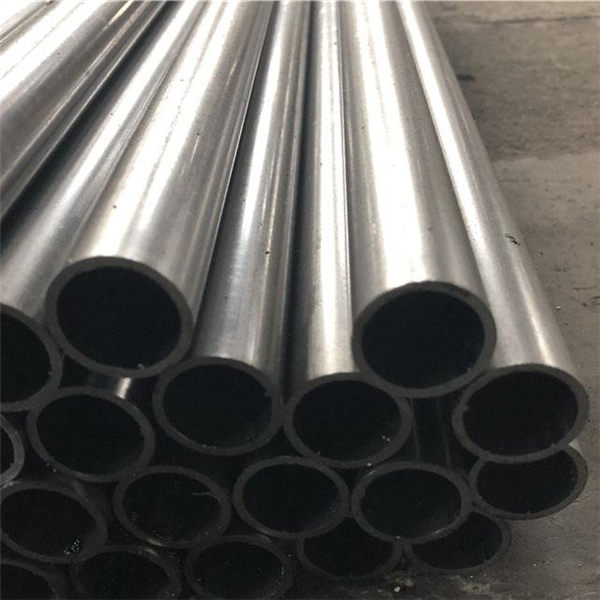

Umgangatho olungileyo waseTshayina ASTM A213 Alloy High Pressure High Pressure Seamless Steel Grade T11 T12 T13 T22 T1 T2 Pipe/Tube

"Ukunyaniseka, ukuVeliswa kwezinto ezintsha, uBungqongqo, kunye nokuSebenza ngokuSebenzayo" inokuba yingcamango eqhubekayo yeshishini lethu kwixesha elide ukuvelisa kunye nabathengi ukuze baphinde babuyele kunye kunye nenzuzo efanayo yokubonelela ngesisombululo sombhobho. Ngoku sine-inventri enkulu ye-Cr Mo ingxubevange yombhobho wentsimbi ukuzalisekisa iminxeba kunye neemfuno zabathengi. Ngabasebenzi abafundileyo, abavelisa izinto ezintsha nabanamandla, sinoxanduva lwazo zonke iinkalo zokubonelela ngesisombululo sombhobho. Ngobutyebi obuphezulu obuphezulu kunye nenkonzo enkulu, sijonge kwiinjongo zokuba ngomnye wababoneleli bezisombululo zombhobho omkhulu kwihlabathi. Simamela ngononophelo ingxelo evela kubathengi bethu kwaye sinikezela ngeempendulo kwangoko. Uya kuziva ngoko nangoko inkonzo yethu yezakhono kunye nenkathalo.

Malunga nepropati ye-Cr Mo pipe, kukho izinto ezininzi zetsimbi ezichaphazelayo. Ubudlelwane phakathi komatshini wepropathi yombhobho kunye nentsimbi engundoqo njengalapha ngezantsi:

I-Carbon (C): Umxholo wekhabhoni kwintsimbi yokunyuka, inqanaba lesivuno, amandla okuqina kunye nobunzima bonyuka, kodwa iplastiki kunye neepropati zempembelelo ziyancipha. Xa umxholo wekhabhoni udlula i-0.23%, ukusebenza kwe-welding yensimbi kuyancipha, ngoko ke ukuba isetyenziselwa i-welding Umxholo wekhabhoni we-low-alloy structural steel ngokuqhelekileyo awudluli i-0.20%. Umxholo wekhabhoni ophezulu uya kunciphisa ukuxhathisa kwe-atmospheric corrosion of steel, kunye ne-high-carbon steel kwi-stock yard evulekileyo kulula ukugqwala; Ukongeza, ikhabhoni inokonyusa i-brittleness ebandayo kunye nobuntununtunu bentsimbi.

I-Silicon (Si): I-Silicon yongezwa njenge-agent yokunciphisa kunye ne-deoxidizer kwinkqubo yokwenza i-steelmaking, ngoko insimbi ebuleweyo iqukethe i-silicon ye-0.15-0.30%. I-silicon inokuphucula kakhulu umda we-elastic, indawo yesivuno kunye nokuqina kokuqina kwentsimbi, ngoko ke isetyenziswa ngokubanzi njengentsimbi ye-elastic. Ukunyuka kwexabiso le-silicon kuya kunciphisa ukusebenza kwe-welding yentsimbi.

IManganese (Mn). Kwinkqubo yokwenza isinyithi, i-manganese yi-deoxidizer efanelekileyo kunye ne-desulfurizer. Ngokuqhelekileyo, insimbi iqulethe i-0.30-0.50% ye-manganese. I-Manganese inokunyusa amandla kunye nokuqina kwentsimbi, ikhulise ukuqina kwentsimbi, iphucule ukusebenza okushushu kwentsimbi, kunye nokunciphisa ukusebenza kwentsimbi.

I-Phosphorus (P): Ngokubanzi, i-phosphorus yinto eyingozi kwintsimbi, eyenza ukuba i-brittleness ebandayo yentsimbi, iphazamise ukusebenza kwe-welding, inciphise iplastiki, kwaye iphazamise ukusebenza kokugoba okubandayo. Ngoko ke, umxholo we-phosphorus kwintsimbi ngokuqhelekileyo ufuneka ukuba ube ngaphantsi kwe-0.045%, kwaye imfuno yensimbi ephezulu iphantsi.

Isulfure (S): Isulfure ikwayinto eyingozi phantsi kweemeko eziqhelekileyo. Yenza intsimbi ishushu ibe brittle, ukunciphisa intsimbi ductility kunye nokuqina, kwaye kubangele iintanda ngexesha forging and rolling. Isulfure nayo iyingozi ekusebenzeni kwe-welding, inciphisa ukuxhathisa ukubola. Ngoko ke, umxholo wesulfure ufunwa ngokubanzi ukuba ube ngaphantsi kwe-0.045%, kwaye imfuno yensimbi ephezulu iphantsi. Ukongeza i-0.08-0.20% sulfure kwintsimbi inokuphucula i-machinability, kwaye ngokuqhelekileyo ibizwa ngokuba yintsimbi yokusika mahhala.

I-Vanadium (V): Ukongeza i-vanadium kwintsimbi inokuphucula i-grains yesakhiwo kunye nokuphucula amandla kunye nokuqina.

I-Niobium (Nb): I-Niobium inokucoca iinkozo kunye nokuphucula ukusebenza kwe-welding.

Ubhedu (Cu): Ubhedu lunokuphucula amandla kunye nokuqina. Ukungalungi kukuba kuxhomekeke kwi-brittleness eshushu ngexesha lokusebenza okushushu, kwaye umxholo wobhedu kwintsimbi ye-scrap uhlala uphezulu.

I-Aluminiyam (Al): I-Aluminiyam yi-deoxidizer esetyenziswa ngokuqhelekileyo kwintsimbi. Inani elincinci le-aluminium lifakwe kwintsimbi yokucoca iinkozo kunye nokuphucula ukuqina kwempembelelo.

| Umgangatho | Grhweba | OD | Tukugxadazela | Phawula |

| I-ASTM A106 | 106B 106C | 21.3-914mm | 2-150mm | umbhobho wentsimbi |

| I-ASTM A213 | T5 T9 T11 T12 T22 T91 | 19-127mm | 2-20mm | Umbhobho wentsimbi wokutshintshisa ubushushu |

| I-ASTM A335 | P5 P9 P11 P12 P22 P36 P91 | 60.3-914mm | 2-150mm | umbhobho wentsimbi |

| I-ASTM A333 | Gr6 Gr8 Gr10 | 21.3-914mm | 2-80mm | Umbhobho wentsimbi wobushushu obuphantsi |

| EN10216-2 | P195GH P235GH P265GH 16Mo3 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4(WB36) X10CrMoVNb9-1 X20CrMoV11-1 | 19-914mm | 2-150mm | umbhobho wentsimbi |

| GB9948 | 10 20 12CrMo 15CrMo 12Cr1MoV 12Cr2Mo 12Cr5Mo 12Cr9Mo | 19-914mm | 2-150mm | Umbhobho oqhekezayo weoyile |

| GB6479 | 10 20 Q345BCDE 12CrMo 15CrMo 12Cr2Mo 12Cr5Mo 10MoWVNb 12SiMoVNb | 19-914mm | 2-150mm | ityhubhu yesichumiso soxinzelelo oluphezulu |