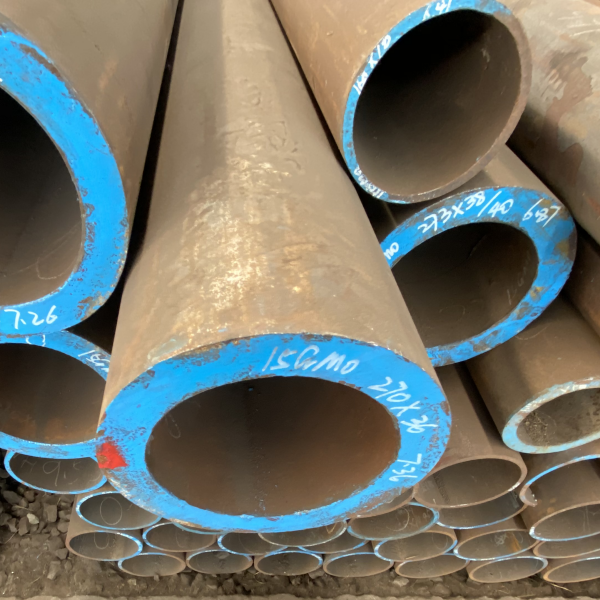

Ukusebenza okuphezulu kweChina i-alloy yensimbi engenamthungo yePipe yePetroleum Cracking GB/T9948 12cr1mo 12cr1MOV 12cr2mo

Ukukhula kwethu kuxhomekeke koomatshini abagqwesileyo, iitalente ezikhethekileyo kunye nemikhosi yobuchwephesha eyomeleziweyo ngokuSebenza okuPhakamileyo kweChina Umbhobho weSsimbi ongenamthungo weAlloy wePetroleum Cracking GB/T9948 12cr1mo 12cr1MOV 12cr2mo, Masisebenzisane ngezandla ukwenza ngokudibeneyo ukwenza okuhle okuzayo. Siyakwamkela ngokunyanisekileyo ukuba undwendwele inkampani yethu okanye uthethe nathi ngentsebenziswano!

Ukukhula kwethu kuxhomekeke koomatshini abaphezulu, iitalente ezikhethekileyo kunye nemikhosi yetekhnoloji eyomeleziweyo ngokuqhubekayoChina Steel Pipe 12cr1mo, Umbhobho wentsimbi 12cr2moUkuza kuthi ga ngoku izinto zethu zithunyelwe empuma Yurophu, kuMbindi Mpuma, eMzantsi-mpuma, eAfrika naseMzantsi Melika njl. . Siyayihlonipha inqununu yethu engundoqo yokunyaniseka kwishishini, eyona nto iphambili kwinkonzo kwaye siya kwenza konke okusemandleni ethu ukubonelela abathengi bethu ngezinto ezikumgangatho ophezulu kunye nenkonzo ebalaseleyo.

Isishwankathelo

| Umgangatho:GB9948-2006 | Unyango loBubushushu: Ukuphelisa/ukunciphisa/ubushushu |

| IQela leBanga: 10, 12CrMo, 15CrMo, 07Crl9Nil0, njl. | Ububanzi bangaphandle (Umjikelezo): 10 - 1000 Mm |

| Ukutyeba: 1 – 100 mm | Isicelo: iityhubhu zokutshintsha ubushushu |

| Ububanzi bangaphandle (Umjikelezo): 10 - 1000 mm | Unyango loMphezulu: NjengeMfuno yoMthengi |

| Ubude: Ubude obuzinzileyo okanye ubude obungenamkhethe | Ubuchwephesha: I-Hot Rolled |

| Ubume beCandelo: Round | Umbhobho oKhethekileyo: Umbhobho oshinyeneyo wodonga |

| Indawo yemvelaphi: eTshayina | Ukusetyenziswa: iityhubhu zokutshintsha ubushushu |

| Isiqinisekiso: ISO9001:2008 | Uvavanyo:UT/MT |

Isicelo

Iityhubhu zentsimbi ezingenamthungo zokuqhekeka kwepetroleum zisebenza kwiityhubhu zentsimbi ezingenamthungo kwiityhubhu zesithando somlilo, iityhubhu zokutshintshiselana ngobushushu kunye nemibhobho yoxinzelelo kwishishini lepetrochemical.

Umgangatho ophezulu we-carbon structural steel grade 20g, 20mng kunye ne-25mng.

I-alloy yezakhiwo zentsimbi: 15mog, 20mog, 12crmog

15CrMoG, 12Cr2MoG, 12CrMoVG, njl

IBanga eliPhambili

IBanga lentsimbi yolwakhiwo oluphezulu lwekhabhoni: 10 #, 20 #

Umgangatho ophezulu we-carbon structural steel grade : 20g, 20mng kunye ne-25mng

I-alloy yezakhiwo zentsimbi: 15mog, 20mog, 12crmog, 15CrMoG, 12Cr2MoG, njl.

ICandelo leMichiza

| No | IBanga | Icandelo leMichiza % | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| Umgangatho ophezulu weCarbon Structural Steel | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| Ingxubevange yentsimbi yesakhiwo | 12CrMo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 |

| 15CrMo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12CrlMo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | |

| 12CrlMoV | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0.025 | 0. 010 | |

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | ||

| 12Cr5MONT | |||||||||||||

| 12Cr9MoI | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| 12Cr9MONT | |||||||||||||

| Intsimbi enganyangekiyo kubushushu | 07Crl9Nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 |

| 07Crl8NillNb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | |

| 07Crl9NillTi | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00~13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0. 015 | |

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | |

IPropati yoomatshini

| Hayi | Ukuqina MPa | Yima kancinci MPa | Ixesha elide emva kokwaphuka A/% | Amandla okufunxa ookrebe kv2/j | Inombolo yokuqina kweBrinell | ||

| umfanekiso | umdluliseli | umfanekiso | umdluliseli | ||||

| hayi ngaphantsi kwe | hayi ngaphezulu kwe | ||||||

| 10 | 335〜475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410〜550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410〜560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440〜640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415〜560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470〜640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450~600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415〜590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MONT | 480〜640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460〜640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9MONT | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9NilO | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | >520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | >520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | >485 | 170 | 35 | 一 | - | 187 HBW | |

| Kwintsimbi enobunzima bodonga obungaphantsi kwe-5mm ityhubhu musa ukwenza umfuniselo wobulukhuni | |||||||

Imfuneko yoVavanyo

Uvavanyo lwe-hydraulic

Uvavanyo lwe-hydraulic luya kwenziwa kwimibhobho yentsimbi nganye nganye. Uxinzelelo oluphezulu lovavanyo luyi-20 MPa. Ngaphantsi koxinzelelo lovavanyo, ixesha lokuzinza aliyi kuba ngaphantsi kwe-10 s, kwaye ukuvuza kombhobho wensimbi akuvumelekanga.

Uvavanyo lokucaba

Uvavanyo lwe-flattening luya kuqhutywa kumbhobho wentsimbi kunye nobubanzi obungaphandle ngaphezu kwe-22 mm

Uvavanyo lomlilo

Umgangatho ophezulu we-carbon structural steel kunye nemibhobho yentsimbi (ekwazi ukumelana nobushushu) kunye nobubanzi obungaphandle obungekho ngaphezu kwe-76 mm kunye nobukhulu bodonga obungekho ngaphezu kwe-8 mm buya kuxhomekeka kuvavanyo olwandisiweyo. Uvavanyo lokuvutha luya kwenziwa kwiqondo lokushisa. Umyinge wangaphandle wokugqabhuka kwesampulu emva kokuba i-taper ye-core core i-60% ye-flaring iya kuhlangabezana neemfuno zetheyibhile 7. Akukho kuphazamiseka okanye ukuqhekeka kuvunyelwe kwisampuli emva kokuvutha. Ngokweemfuno zomfaki-sicelo kwaye kuphawulwe kwikhontrakthi, i-alloy structural steel ingasetyenziselwa ukwandisa uvavanyo.

Itesta engonakalisiyo

Imibhobho yensimbi iya kuba phantsi kokufumanisa impazamo ye-ultrasonic nganye ngokuhambelana namalungiselelo e-GB / T 5777-2008. Ngokweemfuno zomfaki-sicelo, ezinye iimvavanyo ezingonakalisi zingongezwa emva kokuxoxisana phakathi komthengisi kunye nomceli kwaye ziboniswe kwisivumelwano.

Uvavanyo lwe-Intergranular Corrosion

Uvavanyo lwe-Intergranular corrosion luya kuqhutywa kumbhobho wentsimbi ongenasici (ukumelana nobushushu). Indlela yokuvavanya iya kuhambelana namalungiselelo endlela yaseTshayina E kwi-GB / T 4334-2008, kwaye ukuthambekela kwe-intergranular corrosion akuvumelekanga emva kovavanyo.

Emva kothethathethwano phakathi komthengisi kunye nomenzi, kwaye kuphawulwe kwikhontrakthi, umfaki-sicelo unokubeka ezinye iindlela zovavanyo lomhlwa.

Iinkcukacha zeMveliso

Imibhobho yoomatshini/yeKhemikhali&yeSichumiso

I-GB/T8162-2008

ASTM_A519-2006

I-BS EN 10210-1-2006

I-ASTM A53A53M-2012

GB9948-2006

GB6479-2013

GB/T 17396-2009

I-oyile, i-petrochemical, ibhoiler yoxinzelelo oluphezulu, ukusetyenziswa okukhethekileyo kwetyhubhu yebhoyila engenamthungo ityhubhu, ityhubhu yentsimbi engenamthungo kunye ne-oyile engenamthungo.

ICandelo leMichiza

| uphawu | Icandelo leMichiza (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb+Ta | S | P | |

| 15CrMo | 0.12~0.18 | 0.40~0,70 | 0.17~0,37 | 0.80~1.10 | 0.40~0,55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

IPropati yoomatshini

| uphawu | Ukuqina MPa | Yima kancinci MPa | Ubude (%) |

| 15CrMo | 440~640 | 295 | 22 |