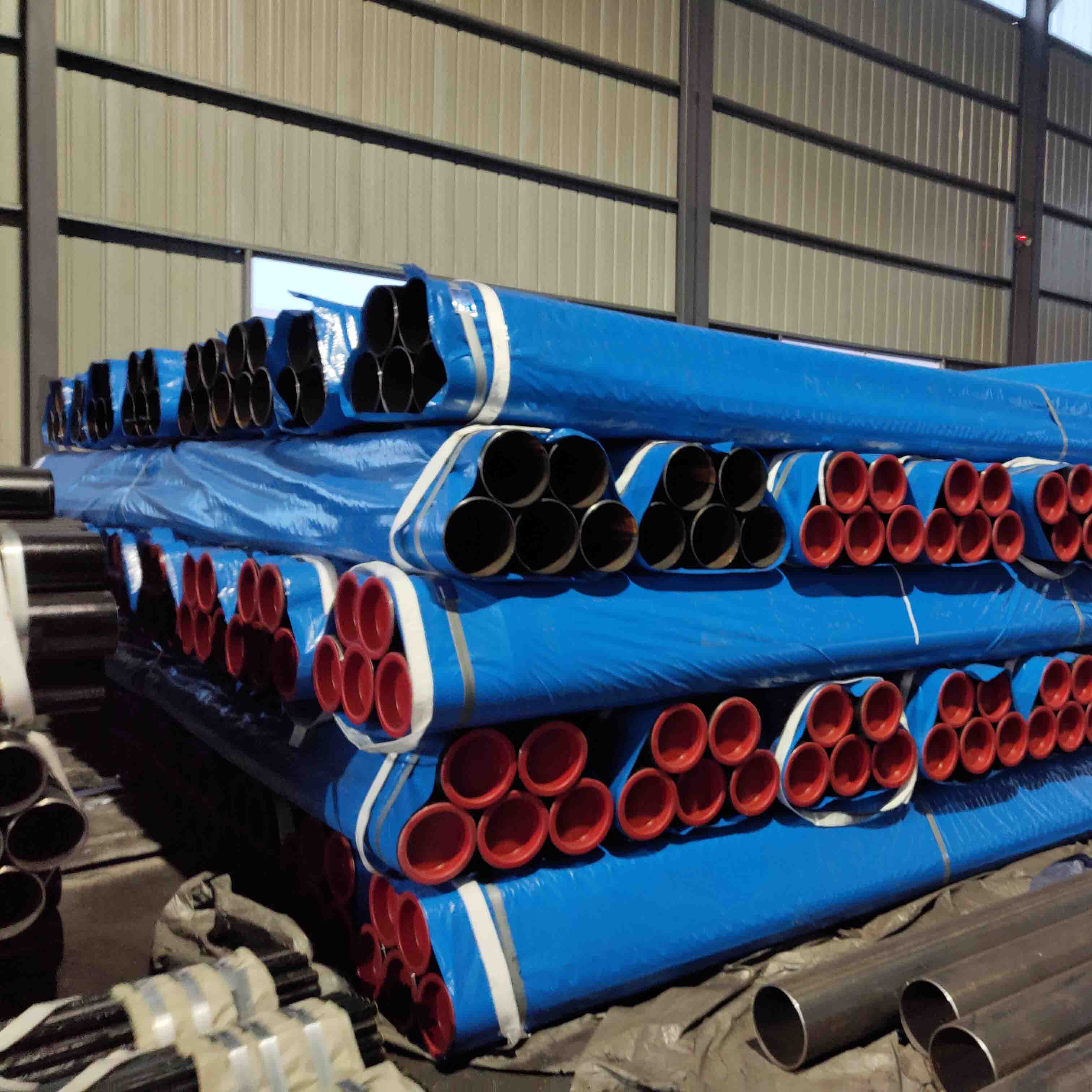

ASME SA-106/SA-106M-2015 pipe ea tšepe ea carbon

| Tloaelo:ASTM SA106 | Alloy kapa Che: Che |

| Sehlopha sa Sehlopha: G.A,GR.B,GR.C joalo-joalo | Kopo: Pipe ea Mokelikeli |

| Botenya: 1 - 100 mm | Surface Treatment: Joalo ka tlhoko ea moreki |

| Bophahamo ba Kantle(Ho potoloha): 10 - 1000 mm | Theknoloji: Hot Rolled |

| Bolelele: Bolelele bo tsitsitseng kapa bolelele bo sa reroang | Phekolo ea mocheso: Ho kopanya/normalizing |

| Sebopeho sa Karolo: Ho potoloha | Pipe e khethehileng: Mocheso o phahameng |

| Sebaka sa Tšimoloho: Chaena | Tšebeliso: Kaho, Lipalangoang tsa Mokelikeli |

| Setifikeiti: ISO9001:2008 | Teko: ECT/CNV/NDT |

Pipe ea tšepe e se nang moeli bakeng sa ts'ebetso ea mocheso o phahamengASTM A106, e loketseng mocheso o phahameng, e sebelisoa haholo ho petroleum, indasteri ea lik'hemik'hale, boiler, seteishene sa motlakase, sekepe, tlhahiso ea mechine, koloi, lifofane, sefofane, matla, jeology, indasteri ea kaho le ea sesole le liindasteri tse ling.

Kereiti ea boleng bo holimo ba tšepe ea sebopeho sa carbon: G.A,GR.B,GR.C

| Sebopeho, % | |||

| Kereiti A | Sehlopha sa B | Mophato C | |

| Khabone, max | 0.25A | 0.3B | 0.35B |

| Manganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus, max | 0.035 | 0.035 | 0.035 |

| Sebabole, max | 0.035 | 0.035 | 0.035 |

| Silicon, min | 0.10 | 0.10 | 0.10 |

| Chrome, maxC | 0.40 | 0.40 | 0.40 |

| Koporo, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| A Bakeng sa phokotso e 'ngoe le e 'ngoe ea 0.01% ka tlase ho boholo ba carbon e boletsoeng, keketseho ea 0.06% ea manganese ka holimo ho palo e boletsoeng e tla lumelloa ho fihla ho boholo ba 1.35%. | |||

| B Ntle le ha moreki a hlalositse ka tsela e nngwe, bakeng sa phokotso e nngwe le e nngwe ya 0.01% ka tlase ho boholo ba khabone e boletsweng, keketseho ya 0.06% ya manganese ka hodima boholo bo boletsweng e tla dumellwa ho fihla ho boholo ba 1.65%. | |||

| C Lintlha tsena tse hlano li kopane ha li na ho feta 1%. | |||

| Kereiti A | Sehlopha sa B | Mophato C | ||||||

| Matla a thata, min, psi(MPa) | 48 000(330) | 60 000(415) | 70 000(485) | |||||

| Ho hlahisa matla, min, psi(MPa) | 30 000(205) | 35 000(240) | 40 000(275) | |||||

| Longitudinal | Phatlalatso | Longitudinal | Phatlalatso | Longitudinal | Phatlalatso | |||

| Elongation ho 2 in. (50 mm), min, % Liteko tsa mantlha tsa elongation transverse strip, le tsa boholo bo nyane bo lekiloeng ka karolo e felletseng | 35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| Ha maemo a potoloha 2-in. Ho sebelisoa mohlala oa teko ea bolelele ba (50-mm). | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Bakeng sa liteko tsa longitudinal strip | A | A | A | |||||

| Bakeng sa liteko tsa transverse strip, theolelo bakeng sa 1/32-in ka 'ngoe. (0.8-mm) phokotseho ea botenya ba lebota ka tlase ho 5/16 in. (7.9 mm) ho tloha botlaaseng ba bolelele ba peresente e latelang e tla etsoa. | 1.25 | 1.00 | 1.00 | |||||

| A Bonyane ba bolelele ho 2 in. (50 mm) bo tla laolwa ke equation e latelang: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| bakeng sa diyuniti tsa inch-pound, le | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| bakeng sa likarolo tsa SI, | ||||||||

| moo: e = bolelele ba bonyane ka 2 in. (50 mm), %, e pota-potiloe ho 0.5% e haufi, A = sebaka se arohaneng sa mohlala oa teko ea tsitsipano, ho 2 (mm2), ho ipapisitsoe le bophara bo boletsoeng kantle kapa bophara bo boletsoeng ka ntle kapa bophara ba mohlala le botenya ba lebota bo boletsoeng, bo pota-potiloeng ho 0.01 in.2 (1 mm2). (Haeba sebaka se baloang ka tsela eo se lekana kapa se seholo ho feta 0.75 in.2 (500 mm2), joale boleng ba 0.75 in.2 (500 mm2) bo tla sebelisoa.), le U = matla a tsitsitseng a boletsoeng, psi (MPa). | ||||||||

Ntle le ho netefatsa sebopeho sa lik'hemik'hale le thepa ea mochini, liteko tsa hydrostatic li etsoa ka bonngoe, 'me ho etsoa liteko tsa ho phatloha le ho bata. . Ho phaella moo, ho na le litlhoko tse itseng bakeng sa microstructure, boholo ba lijo-thollo, le lera la decarburization ea phala ea tšepe e phethiloeng.

Matla a Phepelo: Lithane tse 1000 ka Khoeli Kereiting Ka 'ngoe ea ASTM SA-106 Pipe ea Tšepe

Ka Mengata Le ka Lebokoseng le Matla la Lehong

Matsatsi a 7-14 haeba a le setokong, matsatsi a 30-45 ho hlahisa

30% depsoit, 70% L/C kapa B/L kopi kapa 100% L/C ha u bona