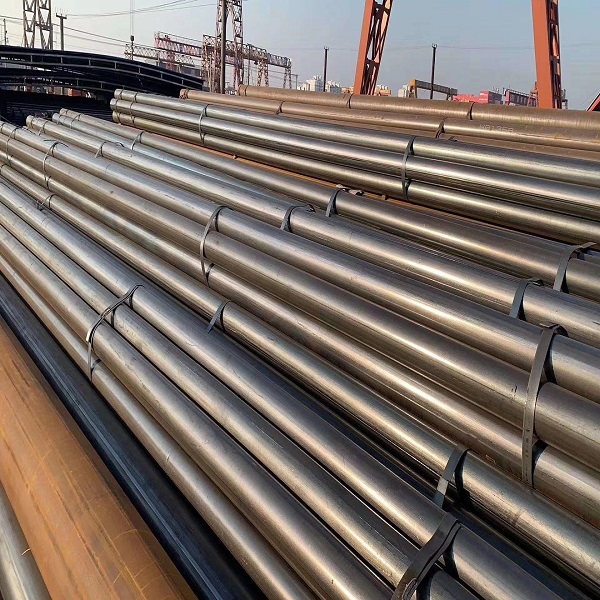

Seamless Alloy Steel Boiler Pipes Superheater alloy pipes Heat Exchanger Tubes

| Tloaelo:ASTM SA 213 | Alloy kapa Che: Alloy |

| Sehlopha sa sehlopha: T5, T9, T11, T22 joalo-joalo | Kopo: Pipe ea boiler / pipe ea mocheso oa mocheso |

| Botenya: 0.4-12.7 limilimithara | Surface Treatment: Joalo ka tlhoko ea moreki |

| Bophahamo ba Kantle(Ho potoloha): 3.2-127 mm | Theknoloji: Hot Rolled |

| Bolelele: Bolelele bo tsitsitseng kapa bolelele bo sa reroang | Phekolo ea mocheso: Normalizing/Tempering/Annealing |

| Sebopeho sa Karolo: Ho potoloha | Pipe e Khethehileng: Pipe e Tenya ea Lerako |

| Sebaka sa Tšimoloho: Chaena | Tšebeliso: Mocheso o moholo, Boiler le Heat Exchanger |

| Setifikeiti: ISO9001:2008 | Teko: ECT/UT |

E sebelisoa haholo ho etsa phala ea tšepe ea boleng bo holimo bakeng sa phala ea boiler ea khatello e phahameng, phala e futhumatsang mocheso le phala e kholo ea mocheso.

Mophato oa tšepe ea boleng bo holimo ea Alloy: T2, T12, T11, T22, T91, T92 joalo-joalo.

| Kereiti ea tšepe | Sebopeho sa Lik'hemik'hale% | ||||||||||

| C | Si | Mn | P, S Max | Cr | Mo | Ke Max | V | Al Max | W | B | |

| T2 | 0.10~0.20 | 0.10~0.30 | 0.30~0,61 | 0.025 | 0.50~0,81 | 0.44 ~ 0,65 | - | - | - | - | - |

| T11 | 0.05~0.15 | 0.50 ~ 1.00 | 0.30~0,60 | 0.025 | 1.00 ~ 1.50 | 0.44 ~ 0,65 | - | - | - | - | - |

| T12 | 0.05~0.15 | Boholo ba 0.5 | 0.30~0,61 | 0.025 | 0.80~1,25 | 0.44 ~ 0,65 | - | - | - | - | - |

| T22 | 0.05~0.15 | Boholo ba 0.5 | 0.30~0,60 | 0.025 | 1.90~2,60 | 0.87~1.13 | - | - | - | - | - |

| T91 | 0.07~0.14 | 0.20~0,50 | 0.30~0,60 | 0.02 | 8.0~9.5 | 0.85~1.05 | 0.4 | 0.18~0,25 | 0.015 | - | - |

| T92 | 0.07~0.13 | Boholo ba 0.5 | 0.30~0,60 | 0.02 | 8.5~9.5 | 0.30~0,60 | 0.4 | 0.15~0,25 | 0.015 | 1.50 ~ 2.00 | 0.001~0.006 |

Bakeng sa T91 e 'ngoe ntle le holimo e boetse e kenyelletsa Nickel 0.4, Va 0.18-0.25, Ni 0.06-0.10, Ni 0.03-0.07, Al 0.02, Ti 0.01, Zr 0.01. A Maximum, ntle le haeba ho bontshitswe palo kapa bonyane. Moo li-ellipses (...) li hlahang tafoleng ena, ha ho hlokahale, 'me tlhahlobo ea element ha ea lokela ho khethoa kapa ho tlalehoa. B E lumelletsoe ho odara T2 le T12 e nang le sulphur content ea 0.045 max. C Ntle le moo, sebakeng sa bonyane ba karo-karolelano ena, thepa e tla ba le boima ba bonyane ba 275 HV boemong bo thatafalitsoeng, bo hlalosoang e le ka mor'a austenitizing le ho pholile mocheso oa kamore empa pele ho mocheso. Teko ea boima e tla etsoa bohareng ba botenya ba sehlahisoa. Khafetsa ea teko ea boima e tla ba lisampole tse peli tsa sehlahisoa ho latela sebaka sa kalafo ea mocheso 'me liphetho tsa tlhahlobo ea boima li tla tlalehoa tlalehong ea tlhahlobo ea thepa.

| Kereiti ea tšepe | Thepa ea Mechini | |||

| T. S | Y. P | Elongation | Ho thatafala | |

| T2 | ≥415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) |

| T11 | ≥415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) |

| T12 | ≥415MPa | ≥ 220MPa | ≥ 30% | 163HBW(85HRB) |

| T22 | ≥415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) |

| T91 | ≥ 585MPa | ≥415MPa | ≥ 20% | 250HBW(25HRB) |

| T92 | ≥ 620MPa | ≥440MPa | ≥ 20% | 250HBW(25HRB) |

Liphapano tse lumelletsoeng ka botenya ba Lerako

| Mabota % | |||||

| kantle bophara ho. mm | 0.095 2.4 le ka tlase | ho feta 0.095 ho ea ho 0.15 2.4-3.8 ho kenyeletsa. | ho feta 0.15 ho ea ho 0.18 3.8-4.6 ho kenyeletsa | ho feta 0.18 ho ea ho 4,6 | |

| katlase katlase katlase katlase | |||||

| seamless, ho chesa ho felile | |||||

| 4inch le ka tlase ho 40 0 35 0 33 0 28 0 | |||||

| ho feta 4 intshi .... 35 0 33 0 28 0 | |||||

| seamless, batang fedile | |||||

| ka tlase | |||||

| 11/2 le tlase | 20 0 | ||||

| ho feta 11/2 | 220 | ||||

Liphapang tse lumelletsoeng tsa botenya ba lebota li sebetsa feela ho li-tubes, ntle le li-tubes tse halefileng ka hare, ha ho phethiloe kapa ho bata.

le pele ho tsukutleha, ho atolosa, ho koba, ho bentša, kapa mesebetsi e meng ea ho etsa lintho

Phapang e lumelletsoeng ka ntle ho Diameter

| bophara ba kantle (mm) | Phapang e lumelletsoeng(mm) | |

| e chesang e felileng ka seamless tube | fedile | tlasa |

| 4" (100mm) le ka tlase | 0.4 | 0.8 |

| 4-71/2"(100-200mm) | 0.4 | 1.2 |

| 71/2-9“(200-225) | 0.4 | 1.6 |

| Li-tubes tse cheselitsoeng le li-tubes tse batang li felile | ||

| ka tlase ho 1"(25mm) | 0.1 | 0.11 |

| 1-11/2"(25-40mm) | 0.15 | 0.15 |

| 11/2-2"(40-50mm) | 0.2 | 0.2 |

| 2-21/2"(50-65mm) | 0.25 | 0.25 |

| 21/2-3"(65-75mm) | 0.3 | 0.3 |

| 3-4"(75-100mm) | 0.38 | 0.38 |

| 4-71/2"(100-200mm) | 0.38 | 0.64 |

| 71/2-9“(200-225) | 0.38 | 1.14 |

Teko ea Hydraustatic:

Pipe ea tšepe e Lokela ho Lekoa Hydraulically One By One. Khatello e phahameng ea teko ke 20 MPa. Tlas'a Khatello ea Teko, Nako ea Botsitso ha ea lokela ho ba ka tlase ho 10 S, 'me Pipe ea tšepe ha ea lokela ho Lula. Kapa Hydraulic Test e ka nkeloa sebaka ke Eddy Current Testing kapa Magnetic Flux Leakage Testing.

Teko e sa Senyeheng:

Liphaephe tse Hlokang Tlhahlobo e Felletseng li Lokela ho hlahlojoa ka mokhoa o le mong ka bonngoe. Ka mor'a hore Puisano e Hloka Tumello ea Mokha 'me e hlalositsoe Konterakang, Litlhahlobo tse ling tse sa senyeheng li ka eketsoa.

Teko ea ho batalatsa:

Li-tubes tse nang le bophara ba ka ntle ho feta 22 mm li tla kengoa tekong ea ho batalla. Ha ho Delamination e Bonahalang, Matheba a Masoeu, Kapa Litšila tse Lokelang ho Etsahala Nakong ea Teko Eohle.

Teko ea Matla:

Bakeng sa Pipe Of Grades P91, P92, P122, And P911, Brinell, Vickers, Or Rockwell Hardness Liteko li Tla Etsoa ka Setšoantšo sa Lotho ka 'ngoe.