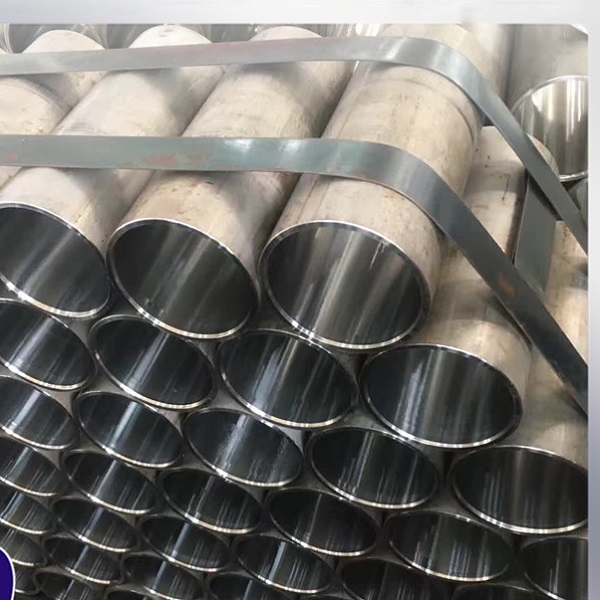

[Kopitsa] Li-tubes tsa tšepe tse se nang Mokotla Bakeng sa ho Cracking Petroleum,GB9948-2006, Sanon Pipe

Kakaretso

E tloaelehileng: GB9948-2006

Sehlopha sa sehlopha: 10,12CrMo,15CrMo, 07Crl9Nil0, joalo-joalo

Botenya: 1 - 100 mm

Bophahamo ba Kantle(Ho potoloha): 10 - 1000 mm

Bolelele: Bolelele bo tsitsitseng kapa bolelele bo sa reroang

Sebopeho sa Karolo: Ho potoloha

Sebaka sa Tšimoloho: Chaena

Setifikeiti: ISO9001:2008

Kalafo Mocheso: Annealing/normalizing/Tempering

Bophara ba Kantle(Lepotoloho): 10 - 1000 Mm

Kopo: li-tubes tsa phapanyetsano ea mocheso

Kalafo ea Bokaholimo: Joalo ka Tlhokahalo ea Bareki

Theknoloji: Hot Rolled

Pipe e Khethehileng: Pipe e Tenya ea Lerako

Tšebeliso: li-tubes tsa phapanyetsano ea mocheso

Teko:UT/MT

Kopo

Li-tubes tsa tšepe tse sa tsitsang bakeng sa ho phunyeha ha peterole li sebetsa ho li-tubes tsa tšepe tse se nang moeli bakeng sa li-tubes tsa sebōpi, li-tubes tsa phapanyetsano ea mocheso le liphaephe tsa khatello indastering ea petrochemical.

Limaraka tsa tšepe tsa boleng bo phahameng ba khabone ke 20g, 20mng le 25mng.

Likarolo tsa tšepe tsa alloy: 15mog, 20mog, 12crmog

15CrMoG, 12Cr2MoG, 12CrMoVG, joalo-joalo

Kereiti e ka Sehloohong

Mophato oa tšepe ea boleng bo holimo ea khabone: 10#,20#

boleng bo phahameng k'habone sebopeho tšepe limaraka : 20g, 20mng le 25mng

Alloy meralo ea tšepe limaraka: 15mog, 20mog, 12crmog, 15CrMoG, 12Cr2MoG, joalo-joalo

Karolo ea Lik'hemik'hale

| No | Kereiti | Karolo ea Lik'hemik'hale % | ||||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | |||

| ≤ | ||||||||||||||

| Litšepe tsa boleng bo phahameng ba carbon structural | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0,65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0,65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | ||

| Motsoako oa tšepe ea sebopeho | 12CrMo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0,55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 15CrMo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | ||

| 12CrlMo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0,65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | ||

| 12CrlMoV | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0.025 | 0. 010 | ||

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | ||

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | |||

| 12Cr5MONTE | ||||||||||||||

| 12Cr9MoI | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | ||

| 12Cr9MONTE | ||||||||||||||

| Tšepe e sa tsitsang mocheso | 07Crl9Nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 | |

| 07Crl8NillNb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | ||

| 07Crl9NillTi | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00~13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0. 015 | ||

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | ||

Thepa ea Mechini

| Che | Tensile MPa | Khefutsa MPa | Nako e telele ka mor'a ho robeha A/% | Matla a ho monya shoka kv2/j | Nomoro ea boima ba Brinell | ||

| setšoantšo | motshelli | setšoantšo | motshelli | ||||

| eseng ka tlase ho | eseng ho feta | ||||||

| 10 | 335〜475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410〜550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410〜560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440〜640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415〜560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470〜640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450-600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415〜590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MONTE | 480〜640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460〜640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9MONTE | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9NilO | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | >520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | >520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | > 485 | 170 | 35 | 一 | - | 187 HBW | |

| Bakeng sa tšepe e nang le botenya ba lebota ka tlase ho 5mm tube u se ke ua etsa liteko tsa boima | |||||||

Tlhokahalo ea Teko

Teko ea Hydraulic

Teko ea Hydraulic e tla etsoa bakeng sa liphaephe tsa tšepe ka bonngoe. Khatello e phahameng ea teko ke 20 MPa. Tlas'a khatello ea teko, nako ea botsitso e ke ke ea e-ba tlase ho 10 s, 'me ho lutla ha pipe ea tšepe ha ho lumelloe.

Teko e bataletseng

Teko ea ho batalla e tla etsoa bakeng sa phala ea tšepe e bophara bo fetang 22 mm

Teko e tukang

Liphaephe tsa tšepe tsa boleng bo phahameng ba carbon le lipeipi tsa tšepe tse se nang mocheso (tse thibelang mocheso) tse bophara ba ka ntle bo sa feteng limilimithara tse 76 le botenya ba lebota bo sa feteng 8 mm li tla ba tlas'a teko e ntseng e hola. Teko ea flaring e tla etsoa ka mocheso oa kamore. Sekhahla se ka ntle sa bophara ba sampuli ka mor'a hore sekhahla se ka holimo se be le karolo ea 60% ea ho phatloha ho tla finyella litlhoko tsa tafole ea 7. Ha ho mapetsong kapa mapheo a lumelloang ka sampuli ka mor'a ho phatloha. Ho ea ka litlhoko tsa motho ea batlang le ho hlokometsoe konteraka, tšepe ea motsoako oa alloy e ka boela ea sebelisoa bakeng sa ho atolosa teko.

Teste e sa senyeheng

Liphaephe tsa tšepe li tla hlahlojoa ke bofokoli ba ultrasonic ka bonngoe ho latela lipehelo tsa GB / T 5777-2008. Ho ea ka litlhoko tsa motho ea batlang, liteko tse ling tse sa senyeheng li ka eketsoa ka mor'a lipuisano pakeng tsa mofani oa thepa le ea batlang 'me li bontšitsoe konteraka.

Teko ea kutu ea intergranular

Teko ea kutu ea intergranular e tla etsoa bakeng sa phala ea tšepe e sa hloekang (e thibelang mocheso). Mokhoa oa teko o tla ba ho latela lipehelo tsa mokhoa oa Sechaena E ho GB / T 4334-2008, mme tšekamelo ea kutu ea intergranular ha e lumelloe kamora tlhahlobo.

Kamora puisano lipakeng tsa morekisi le motho ea batlang, mme e boletsoe konteraka, mokopi a ka khetha mekhoa e meng ea tlhahlobo ea kutu.

![[Kopitsa] Li-tubes tsa tšepe tse se nang Mokotla tsa ho Cracking Petroleum,GB9948-2006, Sanon Pipe Featured Image](http://www.sanonpipe.com/uploads/ff652257.jpg)

![[Kopitsa] Li-tubes tsa tšepe tse se nang Mokotla Bakeng sa ho Cracking Petroleum,GB9948-2006, Sanon Pipe](http://www.sanonpipe.com/uploads/ff652257-300x300.jpg)

![[Kopitsa] Li-tubes tsa tšepe tse se nang Mokotla Bakeng sa ho Cracking Petroleum,GB9948-2006, Sanon Pipe](http://www.sanonpipe.com/uploads/8f454869-300x300.jpg)

![[Kopitsa] Li-tubes tsa tšepe tse se nang Mokotla Bakeng sa ho Cracking Petroleum,GB9948-2006, Sanon Pipe](http://www.sanonpipe.com/uploads/e19d0a6e-300x300.jpg)