Fektheri e theko e tlaase China High Quality Straight Carbon Steel Welded Pipes

Kakaretso

"Laola maemo ka lintlha, bonts'a matla ka boleng". Khoebo ea rona e ikitlaelitse ho theha basebetsi ba sebetsang hantle haholo le ba tsitsitseng mme e lekotse mokhoa o sebetsang oa taolo ea boleng ba Straight Carbon Steel Welded Pipes. Boleng bo botle ke boteng ba feme, ho tsepamisa maikutlo ho tlhokahalo ea bareki ke mohloli oa ho phela le tsoelo-pele ea k'hamphani, Re khomarela botšepehi le boikutlo bo phahameng ba ho sebetsa ka tumelo, ho tsoma ho tla ha hao!

Bakeng sa phala e entsoeng ka tšepe e entsoeng ka carbon, ho na le theknoloji e 2 e ka sehloohong e lokelang ho hlokomeloa hore ke ERW(electric resistance weld) le SAW(submerge arc weld). Liphaephe tse sebelisang theknoloji ena ka bobeli li sebelisoa haholo indastering ea peterole bakeng sa lipalangoang tsa oli le khase, empa kaofela li na le melemo ea tsona, ka hona ts'ebeliso e fapane.

Pipe ea ERW e entsoe ka poleiti ea tšepe, ho na le seam e le 'ngoe feela e cheselitsoeng, 'me hobane mohala o cheselitsoeng oa phala ea ERW o tsoa pompong ea' mè, ha e hloke solder flux, kahoo thepa ea mochine e ntle haholo. 'Me ka lebaka la litšobotsi tsa eona tsa katleho e phahameng ea tlhahiso, theko e tlaase, ho boloka thepa, le ho iketsetsa habonolo, ha ho bapisoa le pipe ea SAW, ERW pipe ke phala ea tšepe e nang le ts'ebetso e tsoetseng pele ea sehlahisoa, boleng bo ka sehloohong le ts'ebetso e batlang e le ea moruo tšimong ea polokelo ea oli le khase. le lipalangoang. Haholo-holo latela kholo ea thekenoloji, boleng haeba tjheseletsa line e ntse e le ho feta le ho feta, ka ho sebelisa thekenoloji e ncha ka ho fetisisa, sepheo ke ho felisa khatello ea kelello, ho nolofatsa le ho ntlafatsa sebopeho, le ho ntlafatsa thepa e pharaletseng ea mochine oa mocheso o amang mocheso. Pipe ena ea mofuta oa ERW ha e khone ho khetholla feela weld, empa hape le coefficient ea weld e fihla ho 1, e hlokomelang ho bapisa ha mohaho oa sebaka sa weld le thepa ea motheo.

Tekanyo ea hona joale ea theknoloji ea SAW e phahame haholo, 'me sekhahla sa phallo se thibela ho lahleheloa ke mocheso ka potlako' me se tsepamisa mohopolo sebakeng sa soldering. Welding ea arc e kentsoeng ka metsing e na le boleng bo phahameng ba seam seam, ts'ebetso e phahameng ea tlhahiso, ha ho khanya ea arc le mosi o monyane. Liphaephe tsa tšepe tse kentsoeng ka tlas'a metsi li sebelisoa haholo likepeng tsa khatello, lisebelisoa tsa liphaephe, maballo, litšiea, maro a khatello e tlase le merero ea sebopeho sa tšepe. Empa indastering ea peterole ea naha e tsoetseng pele, phala ea SAW ha e lumelloe ho kena hobane moeli oa eona, ke China feela phala ea SAW e ntseng e lumelloa indastering ea peterole e nang le moeli.

Boleng bo botle le theko e utloahalang "ke melao-motheo ea rona ea khoebo. Haeba u thahasella lihlahisoa tsa rona le tharollo kapa u na le lipotso, etsa bonnete ba hore u ikutloa u lokolohile ho ikopanya le rona. Re tšepa ho theha likamano tsa tšebelisano le uena haufinyane.

Kopo

E sebelisoa haholo-holo bakeng sa likarolo tsa matla le khatello, le molemong oa kakaretso oa lipeipi tsa mouoane, metsi, khase le moea.

Kereiti e ka Sehloohong

G.A, GR.B

Karolo ea Lik'hemik'hale

| Kereiti | Karolo % ≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Mofuta oa S (peipi e se nang moeli) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| E mofuta (Resistance welded pipe) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Mofuta oa F | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Kakaretso ea lintlha tsena tse hlano ha ea lokela ho ba kholo ho feta 1.00%.

B Bakeng sa phokotso e 'ngoe le e 'ngoe ea 0.01% ho palo e phahameng ea khabone, boholo ba manganese bo lumelloa ho eketseha ka 0.06%, empa boholo bo ke ke ba feta 1.35%.

C Phokotso e 'ngoe le e 'ngoe ea 0.01% ho palo e phahameng ea khabone e tla lumella boholo ba manganese ho eketseha ka 0.06%, empa boholo ha boa lokela ho feta 1.65%.

Thepa ea Mechini

| ntho | G.A | GR.B |

| matla a matla, ≥, psi [MPa] Kotulo e Matla, ≥, psi [MPa] Bolelele ba 2in.kapa 50mm | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Bolelele ba bonyane ba gauge 2in. (50mm) e tla khethoa ka mokhoa o latelang:

e=625000(1940)A0.2/U0.9

e = bolelele ba bonyane ba gauge 2in. (50mm), peresente e lekanyelitsoe ho 0.5% e haufi;

A = E baloa ho ea ka bophara bo ka ntle bo boletsoeng ba tube ea lebitso kapa bophara bo tloaelehileng ba sampole e tsitsitseng le botenya ba eona ba lebota bo boletsoeng, 'me e pota-potiloe sebakeng se haufi-ufi sa sampuli ea 0.01 in.2 (1 mm2), mme E bapisoa le 0.75in.2 (500mm2), ho sa tsotellehe hore na ke efe e nyenyane.

U = matla a fokolang a fokolang, psi (MPa).

B Bakeng sa metswako e fapaneng ya boholo bo fapaneng ba disampole tsa teko le matla a fokolang a behilweng, bolelele bo hlokahalang bo bontshwa ho Lethathamo la X4.1 kapa Lethathamo la X4.2, ho latela ho sebetsa ha lona.

Tlhokahalo ea Teko

Teko ea tensile, teko ea ho khumama, tlhahlobo ea hydrostatic, tlhahlobo ea motlakase e sa senyeheng ea li-welds.

Matla a Phepelo

Matla a Phepelo: Lithane tse 2000 ka Khoeli Kereiting Ka 'ngoe ea ASTM A53/A53M-2012 Pipe ea Tšepe

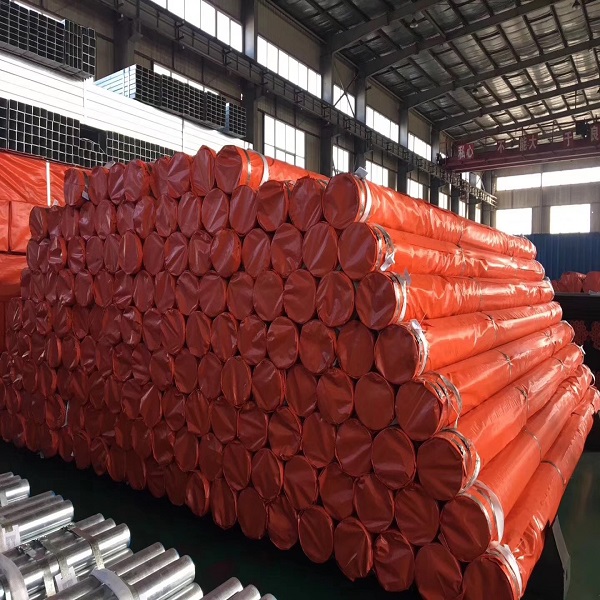

Sephutheloana

Ka Mengata Le ka Lebokoseng le Matla la Lehong

Phano

Matsatsi a 7-14 haeba a le setokong, matsatsi a 30-45 ho hlahisa

Tefo

30% depsoit, 70% L/C kapa B/L kopi kapa 100% L/C ha u bona