Pipe ea Tšepe ea Galvanized

Khamphani ea rona e sebetsa ka ho khetheha ho romelloa kantle ho naha ea tšepe e se nang moelipeipi e entsoeng ka masenke, Pipe e se nang Mokotla, Pipe e entsoeng ka masenke ea SMLS, PEPI e cheselitsoeng ka masenke.

Phapano ke efe lipakeng tsa galvanized tse chesang le tse batang?

Ho futhumatsa-dip galvanizing le serame li ile tsa tiisa phapang:

1. Galvanizing, eo hape e tsejoang e le chesang qoela masenke, o ile a ke ingot qhibiliha ka mocheso phahameng, palo ea lintho tse bonahalang tlatsetso sebakeng, ka nako eo qoelisoa sekotjana tšepe sebopeho sekotjana, karolo tšepe ka mposo ya zinki barbotage . Melemo ea hot-dip galvanizing corrosion ea bokhoni ba hae, ho khomarela le ho thatafala ha ho roala zinki ho molemo.

"Cold plated" kapa "plating", ke hore, tharollo ea letsoai la zinki ka electrolysis, ho plating holim'a ho roala, hangata ha e na ho futhumatsa, e nyenyane ea zinki, tikoloho ea metsi e bonolo haholo ho oa.

2. Dip e chesang e entsoeng ka masenke (galvanizing)

Hot-dip galvanizing ke phekolo ea lik'hemik'hale, ke karabelo ea electrochemical.

Cold galvanizing ke aterese ea 'mele, feela brush holim'a lera la zinki, zinki lera ho bonolo ho oa theoha. Kaho ts'ebelisong ea galvanizing e chesang.

Ts'ebetso e tsoelang pele ea ho qoela ka sekontiri se chesang: tšepe → ho futhumatsa → ho tsidifala ho fihlela mocheso o kentsoeng ka masenke → ho pholisa →

Cold galvanized zinc ke 10-50g/m2 feela, e hanyetsana le kutu ho feta dip e chesang e kenngoeng phapang e ngata. E kolobisitsoe ka theko e tlase haholo.

Hot dip galvanized steel body ke hot dip galvanized surface tlas'a boemo ba ho khomarela ho matla, ha ho bonolo ho oela, leha ho na le dip e chesang.peipi e entsoeng ka masenkecorrosion phenomenon, empa ka nako e telele haholo ho fihlela litlhoko tsa tekheniki, tsa bophelo bo botle.

3. Liphapang tsa theknoloji

Pele ho tsohle, ke phapang pakeng tsa tshebetso: hot-dip galvanizing ke workpiece degreasing, pickling, dipping, ho omisa metsi qoelisoa ka ho qhibiliha zinki nako e itseng ea nako, ka tsosoa.

E boetse e tsejoa e le electro-galvanized batang galvanizing, ke ho sebelisa electrolysis disebediswa sebetsa sengoathoana ka degreasing, pickling metsoako poso ka zinki letsoai tharollo, le hokela anode electrolysis thepa; sebakeng ho pholletsa le likarolo tsa zinki poleiti e hokahantsoeng le thepa electrolysis positive, matla a ho, tšebeliso ea hona joale ho tloha cathode ho anode ea motsamao oa tataiso ea workpiece tla beha ka mposo ya zinki.

Zinc e qetile phapang: ha ho na serame se batang se chesang se chesang se nang le ponahalo e khanyang e khanyang, empa botenya ba zinki e koahetsoeng ka likarolo tse batang tsa galvanizing ea hot-dip galvanizing ke makhetlo a 'maloa. Galvanized corrosion resistance e boetse ke makhetlo a 'maloa.

Kakaretso

Kopo

E sebelisoa haholo-holo bakeng sa likarolo tsa matla le khatello, le molemong oa kakaretso oa lipeipi tsa mouoane, metsi, khase le moea.

Kereiti e ka Sehloohong

G.A, GR.B

Karolo ea Lik'hemik'hale

| Kereiti | Karolo % ≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Mofuta oa S (peipi e se nang moeli) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| E mofuta (Resistance welded pipe) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Mofuta oa F | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Kakaretso ea lintlha tsena tse hlano ha ea lokela ho ba kholo ho feta 1.00%.

B Bakeng sa phokotso e 'ngoe le e 'ngoe ea 0.01% ho palo e phahameng ea khabone, boholo ba manganese bo lumelloa ho eketseha ka 0.06%, empa boholo bo ke ke ba feta 1.35%.

C Phokotso e 'ngoe le e 'ngoe ea 0.01% ho palo e phahameng ea khabone e tla lumella boholo ba manganese ho eketseha ka 0.06%, empa boholo ha boa lokela ho feta 1.65%.

Thepa ea Mechini

| ntho | G.A | GR.B |

| matla a matla, ≥, psi [MPa] Kotulo e Matla, ≥, psi [MPa] Bolelele ba 2in.kapa 50mm | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Bolelele ba bonyane ba gauge 2in. (50mm) e tla khethoa ka mokhoa o latelang:

e=625000(1940)A0.2/U0.9

e = bolelele ba bonyane ba gauge 2in. (50mm), peresente e lekanyelitsoe ho 0.5% e haufi;

A = E baloa ho ea ka bophara bo ka ntle bo boletsoeng ba tube ea lebitso kapa bophara bo tloaelehileng ba sampole e tsitsitseng le botenya ba eona ba lebota bo boletsoeng, 'me e pota-potiloe sebakeng se haufi-ufi sa sampuli ea 0.01 in.2 (1 mm2), mme E bapisoa le 0.75in.2 (500mm2), ho sa tsotellehe hore na ke efe e nyenyane.

U = matla a fokolang a fokolang, psi (MPa).

B Bakeng sa metswako e fapaneng ya boholo bo fapaneng ba disampole tsa teko le matla a fokolang a behilweng, bolelele bo hlokahalang bo bontshwa ho Lethathamo la X4.1 kapa Lethathamo la X4.2, ho latela ho sebetsa ha lona.

Tlhokahalo ea Teko

Teko ea tensile, teko ea ho khumama, tlhahlobo ea hydrostatic, tlhahlobo ea motlakase e sa senyeheng ea li-welds.

Matla a Phepelo

Matla a Phepelo: Lithane tse 2000 ka Khoeli Kereiting Ka 'ngoe ea ASTM A53/A53M-2012 Pipe ea Tšepe

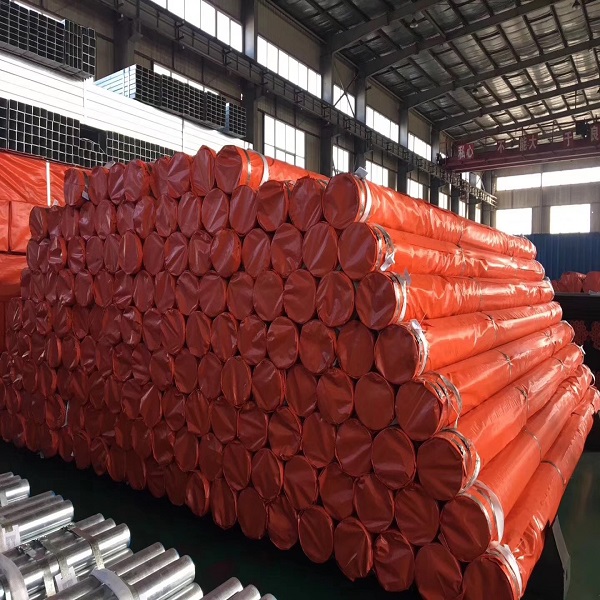

Sephutheloana

Ka Mengata Le ka Lebokoseng le Matla la Lehong

Phano

Matsatsi a 7-14 haeba a le setokong, matsatsi a 30-45 ho hlahisa

Tefo

30% depsoit, 70% L/C kapa B/L kopi kapa 100% L/C ha u bona