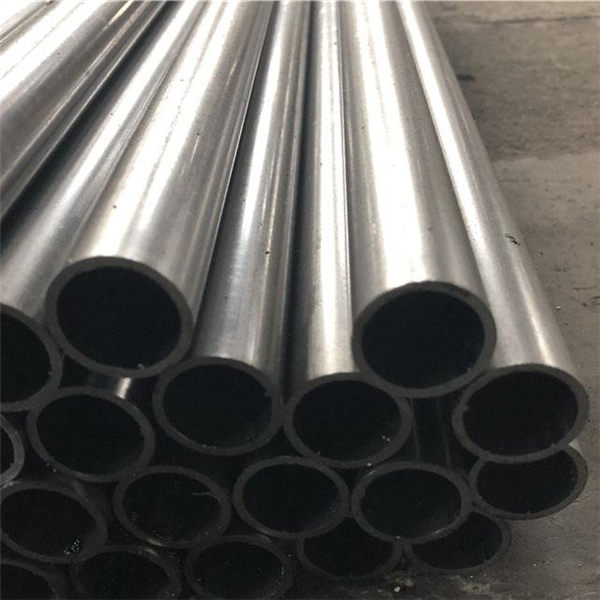

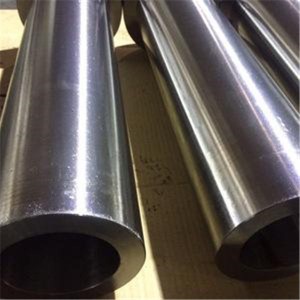

Boleng bo botle China ASTM A213 Alloy High Pressure Seamless Steel Grade T11 T12 T13 T22 T1 T2 Pipe/Tube

"Botšepehi, Boqapi, Bokhabane, le Ts'ebetso" e ka ba mohopolo o tsitsitseng oa khoebo ea rona ho fihlela nako e telele ho hlahisa hammoho le bareki bakeng sa ho lumellana le phaello e kopanetsoeng bakeng sa tharollo ea liphaephe. Hona joale re na le lethathamo le leholo la pipe ea tšepe ea Cr Mo alloy ho phethahatsa lipitso le litlhoko tsa bareki ba rona. Ka basebetsi ba rutehileng, ba macha le ba mahlahahlaha, re bile le boikarabello bakeng sa likarolo tsohle tsa phepelo ea tharollo ea liphaephe. Ka lisebelisoa tse ngata tsa boleng bo holimo le litšebeletso tse ngata, re habile sepheo sa ho ba e mong oa barekisi ba kholo ka ho fetisisa lefatšeng. Re mamela maikutlo a bareki ba rona ka hloko mme re fana ka likarabo hang hang. Hang-hang u tla utloa tšebeletso ea rona e nang le tsebo le e hlokolosi.

Mabapi le thepa ea Cr Mo pipe, ho na le likarolo tse ngata tsa tšepe tse e amang. Kamano pakeng tsa thepa ea mochini ea pipe le ntho e ka sehloohong ea tšepe e ka tlase:

Carbon (C): Likahare tsa carbon ka har'a tšepe lia eketseha, ntlha ea tlhahiso, matla a thata le ho thatafala lia eketseha, empa polasetiki le thepa ea tšusumetso lia fokotseha. Ha carbon content e feta 0.23%, ts'ebetso ea ho tjheseletsa ea tšepe ea senyeha, kahoo haeba e sebelisetsoa ho cheselletsa Thepa ea carbon ea tšepe e tlaase ea alloy ha e fete 0.20%. Likahare tse phahameng tsa k'habone le tsona li tla fokotsa khanyetso ea sepakapaka ea tšepe, 'me tšepe e nang le k'habone e phahameng ka jareteng ea setoko e bulehileng ho bonolo ho rusa; ho feta moo, k'habone e ka eketsa brittleness e batang le kutloisiso ea botsofali ea tšepe.

Silicon (Si): Silicon e eketsoa e le moemeli oa ho fokotsa le deoxidizer ts'ebetsong ea ho etsa tšepe, kahoo tšepe e bolailoeng e na le silicon ea 0.15-0.30%. Silicon e ka ntlafatsa haholo moeli oa rekere, ntlha ea tlhahiso le matla a ts'ebetso ea tšepe, ka hona e sebelisoa haholo joalo ka tšepe ea elastic. Keketseho ea palo ea silicon e tla fokotsa ts'ebetso ea tšepe ea tšepe.

Manganese (Mn). Ts'ebetsong ea ho etsa tšepe, manganese ke deoxidizer e ntle le desulfurizer. Ka kakaretso, tšepe e na le 0.30-0.50% ea manganese. Manganese e ka eketsa matla le ho tiea ha tšepe, ea eketsa ho thatafala ha tšepe, ea ntlafatsa ts'ebetso e chesang ea tšepe, 'me ea fokotsa ts'ebetso ea tšepe ea tšepe.

Phosphorus (P): Ka kakaretso, phosphorus ke ntho e kotsi ka har'a tšepe, e eketsang brittleness e batang ea tšepe, e senya ts'ebetso ea welding, e fokotsa polasetiki, 'me e senya ts'ebetso e batang ea ho kobeha. Ka hona, lintho tse nang le phosphorus ka tšepe ka kakaretso li hlokeha ho ba tlase ho 0.045%, 'me tlhokahalo ea tšepe ea boleng bo phahameng e tlaase.

Sebabole (S): Sebabole le sona ke ntho e kotsi tlas'a maemo a tloaelehileng. Etsa hore tšepe e chese e be brittle, fokotsa ho ductility le ho tiea ha tšepe, 'me u bake mapetsong nakong ea ho qhekella le ho bilika. Sebabole se boetse se kotsi ts'ebetsong ea welding, e fokotsa ho hanyetsa ho bola. Ka hona, sebabole ka kakaretso se hlokeha ho ba tlase ho 0.045%, 'me tlhokahalo ea tšepe ea boleng bo phahameng e tlaase. Ho eketsa 0.08-0.20% sebabole ho tšepe ho ka ntlafatsa machinability, 'me ka kakaretso e bitsoa tšepe e sehang mahala.

Vanadium (V): Ho kenyelletsa vanadium ho tšepe ho ka ntlafatsa lithollo tsa sebopeho le ho ntlafatsa matla le ho tiea.

Niobium (Nb): Niobium e ka ntlafatsa lijo-thollo le ho ntlafatsa ts'ebetso ea ho cheselletsa.

Koporo (Cu): Koporo e ka ntlafatsa matla le ho tiea. Bothata ke hore ho na le tšekamelo ea ho ba le brittleness e chesang nakong ea mosebetsi o chesang, 'me lihlahisoa tsa koporo ka tšepe ea tšepe hangata li phahame.

Aluminium (Al): Aluminium ke deoxidizer e sebelisoang hangata ka tšepe. Palo e nyane ea aluminium e eketsoa tšepeng ho hloekisa lithollo le ho ntlafatsa matla a ts'usumetso.

| Standard | Grade | OD | Thickness | Remarke |

| ASTM A106 | 106B 106C | 21.3-914 limilimithara | 2-150 limilimithara | phala ea tšepe |

| ASTM A213 | T5 T9 T11 T12 T22 T91 | 19-127 limilimithara | 2-20mm | Pipe ea tšepe ea mocheso oa mocheso |

| ASTM A335 | P5 P9 P11 P12 P22 P36 P91 | 60.3-914 limilimithara | 2-150 limilimithara | phala ea tšepe |

| ASTM A333 | Gr6 Gr8 Gr10 | 21.3-914 limilimithara | 2-80mm | Phaephe ea tšepe ea mocheso o tlase |

| EN10216-2 | P195GH P235GH P265GH 16Mo3 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4(WB36) X10CrMoVNb9-1 X20CrMoV11-1 | 19-914 limilimithara | 2-150 limilimithara | phala ea tšepe |

| GB9948 | 10 20 12CrMo 15CrMo 12Cr1MoV 12Cr2Mo 12Cr5Mo 12Cr9Mo | 19-914 limilimithara | 2-150 limilimithara | Peipi e petsolang oli |

| GB6479 | 10 20 Q345BCDE 12CrMo 15CrMo 12Cr2Mo 12Cr5Mo 10MoWVNb 12SiMoVNb | 19-914 limilimithara | 2-150 limilimithara | Tube ea manyolo e nang le khatello e phahameng |