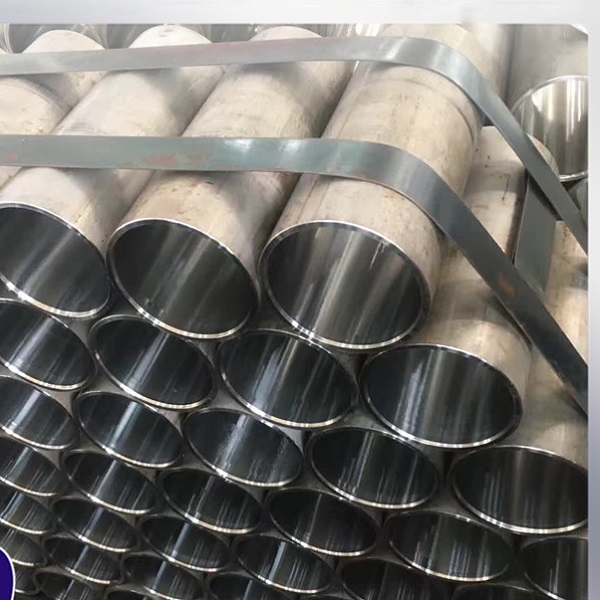

SA213 tube ea boiler ea khatello e phahamengletoto ke atube ea boiler ea khatello e phahamengletoto. E loketse li-tubes tse seamless ferritic le austenitic steel tse nang le botenya bo tlase ba lebota bakeng sa liboilers le li-superheaters le li-tubes tsa tšepe tsa austenitic bakeng sa li-heaters tsa mocheso.

Liphaephe tse futhumatsang holim'a metsi tse sebelisoang ka li-boilers tse tlase le tse mahareng (khatello ea ho sebetsa hangata ha e kholo ho feta 5.88Mpa, mocheso o sebetsang o ka tlase ho 450 ℃); e sebelisoang ho li-boilers tsa khatello e phahameng (khatello ea ho sebetsa hangata e ka holimo ho 9.8Mpa, mocheso o sebetsang o pakeng tsa 450 ℃~650 ℃) ) li-tubes tse futhumatsang holim'a metsi, li-superheaters, li-reheaters, li-tubes tsa indasteri ea petrochemical, joalo-joalo.

ASME SA213 T12phala ea tšepe ea alloy, moetapele oa liphaephe tsa tšepe tse se nang seamless tsa Amerika, e sebelisoa haholo ho petroleum, indasteri ea lik'hemik'hale, matla a motlakase le masimo a mang a indasteri. Mofuta ona oa phala ea tšepe o entsoe ka tšepe ea boleng bo holimo. Ka mor'a ts'ebetso e hlokolosi ka mekhoa e mengata, e na le matla a phahameng le khanyetso e phahameng ea kutu. E ka fihlela litlhoko tsa tšebeliso libakeng tse fapaneng tse rarahaneng.

Ts'ebetso ea eona ea tlhahiso e rarahane ebile e ntle haholo, ho kenyelletsa ho qhibiliha, ho thellisa, ho phunya, ho taka ho batang, kalafo ea mocheso le likhokahano tse ling. Nakong ea ts'ebetso ea tlhahiso, phala ea tšepe e fumana liphoso tse ngata le tlhahlobo e sa senyeheng ho netefatsa boleng ba eona bo botle le ho tšepahala. Ho boetse ho na le tlhahlobo e fapaneng ea lik'hemik'hale, tlhahlobo ea metallographic le liteko tse ling ho netefatsa hore sebopeho sa eona, sebopeho sa mokhatlo, ts'ebetso le matšoao a mang a fihlela litlhoko tse tloaelehileng.

Litšobotsi tsaASME SA213 T12pipe ea tšepe ea alloy ke tse latelang:

1. Matla a phahameng: E na le matla a phahameng a tsitsipano le ntlha ea lihlahisoa, 'me e khona ho mamella meroalo e meholo le liphello.

2. Ho hanyetsa ho hoholo ho matla: E na le khanyetso e matla ea kutu libakeng tse sa tšoaneng tse rarahaneng, tse kang li-acids, alkalis, letsoai le lintho tse ling tsa lik'hemik'hale le libaka tse feteletseng tse kang mocheso o phahameng le mocheso o tlaase.

3. Ts'ebetso e ntle ea welding: E entsoe ka tšepe ea boleng bo phahameng, ha e na monyetla oa ho mapetsong, li-pores le mathata a mang nakong ea welding, ho netefatsa boleng ba welding le ho tšepahala.

4. Mefuta e mengata ea lisebelisoa: E sebelisoa haholo ho petroleum, indasteri ea lik'hemik'hale, matla a motlakase le masimo a mang a indasteri, a kang liphaephe tsa oli le khase, li-boilers, li-reactors le lisebelisoa tse ling.

Nako ea poso: Nov-29-2023