15Mo3 (15MoG) : Ke phala ea tšepe e tloaelehileng ea DIN17175. Ke tube e nyane ea bophara ba carbon molybdenum bakeng sa boiler le superheater, le mofuta oa pearlescent tšepe ea matla a chesang. Ka 1995, e ile ea fetisetsoa hoGB5310mme e rehiloe 15MoG. Sebopeho sa eona sa lik'hemik'hale se bonolo, empa se na le molybdenum, kahoo se na le matla a molemo a mocheso ho feta carbon steel ha se ntse se boloka ts'ebetso e tšoanang le ea carbon steel. Ka lebaka la ts'ebetso ea eona e ntle, theko e tlaase, e 'nile ea sebelisoa haholo lefatšeng. Leha ho le joalo, tšepe e na le tšekamelo ea ho graphitization ka mor'a ts'ebetso ea nako e telele ka mocheso o phahameng, kahoo mocheso oa eona oa ts'ebetso o lokela ho laoloa ka tlase ho 510 ℃, 'me palo ea Al e kenyelletsoeng ka ho qhibiliha e lokela ho lekanyetsoa ho laola le ho lieha ts'ebetso ea graphitization. Tube ena ea tšepe e sebelisoa haholo bakeng sa mocheso o tlase oa mocheso le mocheso o tlase oa ho futhumatsa mocheso. Thempereichara ea lebota e ka tlase ho 510 ℃. Sebopeho sa eona sa lik'hemik'hale C0.12-0.20, SI0.10-0.35, MN0.40-0.80, S≤0.035, P≤0.035, MO0.25-0.35; Boemo bo tloaelehileng ba matla σs≥270-285, σb≥450-600 MPa; Plastiki Delta 22 kapa ho feta.

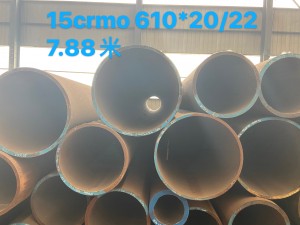

15CrMoG:GB5310-95 tšepe (e tsamaellanang le 1CR-1/2Mo le 11/4CR-1/2MO-Si tšepe e sebelisoang haholo lefatšeng), litaba tsa eona tsa chromium li phahame ho feta 12CrMo tšepe, kahoo e na le matla a phahameng a mocheso ho 500-550 ℃. Ha mocheso o feta 550 ℃, matla a mocheso a tšepe a fokotseha haholo. Ha e sebelisoa nako e telele ho 500-550 ℃, graphitization ha e etsahale, empa carbide spheroidization le alloying element redistribution li etsahala, tse lebisang ho fokotseha ha matla a mocheso a tšepe. Tšepe e na le khanyetso e ntle ea ho phomola ho 450 ℃. Ts'ebetso ea eona ea ho etsa lipeipi le ts'ebetso ea welding e ntle. E sebelisoa haholo-holo e le mouoane oa khatello e phahameng le e mahareng le lebokose le kopanyang le parameter ea mouoane ka tlase ho 550 ℃, tube ea superheater e nang le mocheso o ka tlaase ho 560 ℃, joalo-joalo. lik'hemik'hale tsa eona tsa C0.12-0.18, Si0.17-0.37, MN0.40-0.70, S≤0.030, S≤0.030, P. CR0.80-1.10, MO0.40-0.55; Tlas'a boemo bo tloaelehileng ba mocheso, tekanyo ea matla σs≥235, σb≥440-640 MPa; Leqhoa la polasetiki leq 21.

T22 (P22), 12Cr2MoG: T22 (P22) liASME SA213 (SA335) lisebelisoa tsa khoutu, tse kenyellelitsoeng hoGB5310-95. Letotong la litšepe tsa CR-Mo, ts'ebetso ea eona ea matla a mocheso e batla e phahame, mocheso o ts'oanang le matla a tšoarellang le khatello e lumelletsoeng ho feta 9CR-1Mo tšepe e phahameng le ho feta, kahoo e sebelisoa haholo ho matla a tsoang kantle ho mocheso, matla a nyutlelie le likepe tsa khatello. Leha ho le joalo, moruo oa eona oa tekheniki o tlase ho 12Cr1MoV ea rona, ka hona, ha e sebelisoe haholo tlhahisong ea liboiler tsa motlakase oa lapeng. Sebelisa feela ha ho hlokahala (haholo-holo ha e entsoe le ho etsoa ho latela khoutu ea ASME). Tšepe ha e utloe kalafo ea mocheso 'me e na le polasetiki e tšoarellang e phahameng le ts'ebetso e ntle ea welding. T22 e nyenyane ea bophara ba tube e sebelisoa haholo-holo e le mocheso oa lebota la tšepe ka tlase ho 580 ℃ superheater le reheater futhumatsang holim'a tube, joalo-joalo,P22tube e kholo ea bophara e sebelisoa haholo mocheso oa lerako la tšepe ha o fete 565 ℃ superheater / reheater coupling box le phala e kholo ea mouoane. Sebopeho sa eona sa lik'hemik'hale C≤0.15, Si≤0.50, MN0.30-0.60, S≤0.025, P≤0.025, CR1.90-2.60, MO0.87-1.13; Tlas'a boemo bo tloaelehileng ba mocheso, tekanyo ea matla σs≥280, σb≥450-600 MPa; Plastiki delta 20 kapa ho feta.

12Cr1MoVG:GB5310-95 nano standard steel, ke khatello e phahameng ea lapeng, khatello e phahameng haholo, subcritical power plant boiler superheater, lebokose la pokello le tšepe e kholo ea mouoane e sebelisoang haholo. Sebopeho sa lik'hemik'hale le lisebelisoa tsa mochini tsa poleiti ea 12Cr1MoV li tšoana hantle. Sebopeho sa eona sa lik'hemik'hale se bonolo, kakaretso ea alloy content e ka tlase ho 2%, bakeng sa carbon e tlaase, mofuta o tlaase oa pearlescent oa tšepe ea tšepe e chesang. Vanadium e ka theha carbide VC e tsitsitseng ka khabone, e ka etsang hore chromium le molybdenum ka tšepe li be teng ka mokhoa o ikhethileng ho ferrite, le ho fokotsa sekhahla sa phetisetso ea chromium le molybdenum ho tloha ferrite ho ea ho carbide, e le hore tšepe e tsitsitse haholoanyane mochesong o phahameng. Kakaretso ea likarolo tse kopantsoeng ka tšepe ena ke halofo feela ea tšepe ea 2.25 CR-1Mo e sebelisoang haholo linaheng tse ling, empa matla a tšoarellang ho 580 ℃ le 100,000 h ke 40% e phahameng ho feta ea ho qetela. Ho feta moo, ts'ebetso ea tlhahiso e bonolo mme ts'ebetso ea welding e ntle. Hafeela ts'ebetso ea phekolo ea mocheso e le thata, ts'ebetso e pharaletseng le ts'ebetso ea matla a mocheso e ka khotsofatsoa. Ts'ebetso ea 'nete ea seteishene sa motlakase e bonts'a hore phala e kholo ea mouoane ea 12Cr1MoV e ntse e ka sebelisoa kamora ts'ebetso e bolokehileng ho 540 ℃ bakeng sa lihora tse 100,000. Thepa e nang le bophara bo boholo e sebelisoa haholo e le lebokose la pokello le mouoane o ka sehloohong oa paramente ea mouoane e ka tlase ho 565 ℃, 'me tube e nang le bophara bo nyane e sebelisoa bakeng sa pompo ea mocheso ea boiler ea mocheso oa lebota la tšepe ka tlase ho 580 ℃.

12Cr2MoWVTiB (G102) :Gb5310-95 ka tšepe, bakeng sa tsoelo-pele ea Chaena lilemong tsa bo-1960, k'habone e tlaase, alloy e tlaase (e fokolang ea mefuta e sa tšoaneng) mofuta oa Bainite o chesang matla a tšepe, ho tloha lilemong tsa bo-1970 o kenyelelitsoe Lefapheng la Metallurgical Industry standard YB529-70 'me hona joale e le boemo ba naha, qetellong ea 1980, tšepe ea Lekala la Metallurgical ea Lekala la Metal le Metal ka Lekala la Metallurgical le Lekala la Metal. boitsebiso bo kopanetsoeng. Tšepe e na le lisebelisoa tse ntle tsa mochini, 'me matla a eona a mocheso le mocheso oa ts'ebeletso li phahame ho feta tsa litšepe tse ts'oanang kantle ho naha, li fihla boemong ba litšepe tse ling tsa chromium-nickel austenitic ho 620℃. Sena ke hobane tšepe e na le mefuta e mengata ea likarolo tsa alloying, hape e eketsoa ho ntlafatsa khanyetso ea oxidation ea lintho tse kang Cr, Si, kahoo mocheso o phahameng oa litšebeletso o ka fihla ho 620 ℃. Ts'ebetso ea 'nete ea seteishene sa matla e bontša hore sebopeho le thepa ea pipe ea tšepe ha e fetohe haholo ka mor'a ts'ebetso ea nako e telele. E sebelisoa haholo joalo ka li-tube tsa superheater le tube ea reheater bakeng sa boiler ea paramethara e phahameng haholo e nang le mocheso oa tšepe ≤620 ℃. Sebopeho sa eona sa lik'hemik'hale C0.08-0.15, Si0.45-0.75, MN0.45-0.65, S≤0.030, P≤0.030, CR1.60-2.10, MO0.50-0.65, V0.28-0.42, 05-05-0.08, 05-05. B0.002-0.008; Tlas'a boemo bo tloaelehileng ba mocheso, tekanyo ea matla σ≥345, σb≥540-735 MPa; Leqhoa la polasetiki leq 18.

Sa-213t91 (335P91) : Nomoro ea tšepe ka hareASME SA-213(335) e tloaelehileng. E hlahisoa ke Rubber Ridge National Laboratory ea United States of America, e sebelisoang ka matla a nyutlelie (e ka boela ea sebelisoa likarolong tse ling) likarolo tse phahameng tsa mocheso oa mocheso oa thepa, tšepe e thehiloe holim'a tšepe ea T9 (9CR-1MO), moeling oa carbon content, e laola ka thata-thata litaba tsa P le S le likarolo tse ling tse setseng ka nako e le 'ngoe, mofuta o mocha oa mocheso o entsoeng ka mocheso o entsoeng ka mocheso o entsoeng ka mocheso o matla o entsoeng ka mocheso o matla. 0.030-0.070% N, 0.18-0.25% V le 0.06-0.10% Nb ho finyella litlhoko tsa ntlafatso ea lijo-thollo. Ho joaloASME SA-213column standard steel, e ileng ya fetisetswa hoGB5310standard ka 1995 mme kereiti ke 10Cr9Mo1VNb. Tekanyetso ea machaba ea ISO/ DIS9399-2 e thathamisitsoe e le X10 CRMOVNB9-1.

Ka lebaka la boholo ba chromium (9%), khanyetso ea eona ea oxidation, ho hanyetsa kutu, matla a mocheso o phahameng le tšekamelo ea ho se graphitization e molemo ho feta ea tšepe e tlaase ea alloy. Molybdenum (1%) haholo-holo e ntlafatsa matla a mocheso o phahameng 'me e thibela tšekamelo ea ho chesa ha tšepe ea chromium. Ha ho bapisoa le T9, thepa ea tjheseletsa le mokhathala oa mogote e ntlafatsoa, matla a tšoarellang ho 600 ℃ ke makhetlo a mararo ho feta a morao-rao, 'me ho hanyetsa mocheso o phahameng oa mocheso oa T9 (9CR-1Mo) ho bolokoa. Ha ho bapisoa le tšepe e sa jeleng ea austenitic, coefficient ea katoloso e nyane, conductivity ea mocheso e ntle, 'me e na le matla a phahameng a tšoarellang (joalo ka TP304 austenitic steel ratio, ho fihlela mocheso o matla o le 625 ℃, mocheso o lekanang oa khatello ea maikutlo ke 607 ℃). Ka hona, e na le thepa e ntle e felletseng ea mochini, sebopeho se tsitsitseng le thepa pele le ka mor'a botsofali, thepa e ntle ea welding le ts'ebetso, matla a phahameng a tšoarellang le ho hanyetsa oxidation. E sebelisoa haholo-holo bakeng sa ho futhumatsa le ho futhumatsa ka mocheso oa tšepe ≤650 ℃ ka boiler. Sebopeho sa eona sa lik'hemik'hale C0.08-0.12, Si0.20-0.50, MN0.30-0.60, S≤0.010, P≤0.020, CR8.00-9.50, MO0.85-1.05, V0.18-0.25, Al≤0.010, Al≤0.010. N0.03-0.07; Tlas'a boemo bo tloaelehileng ba mocheso, tekanyo ea matla σs≥415, σb≥585 MPa; Plastiki delta 20 kapa ho feta.

Nako ea poso: Sep-07-2022