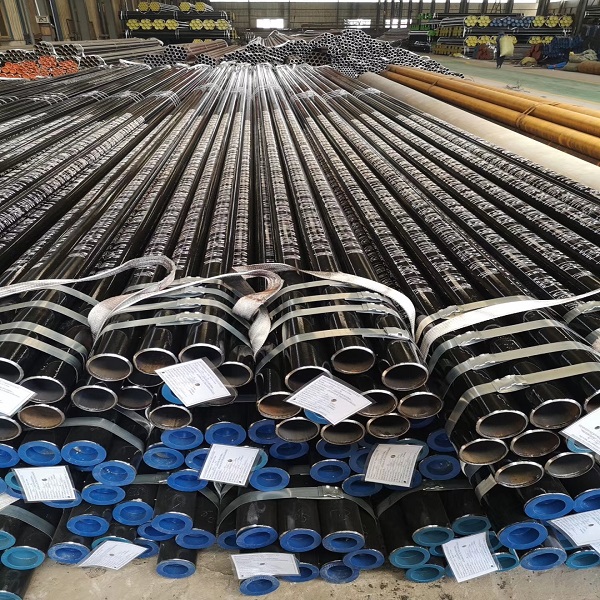

Peipi e entsoeng ka mochini e se nang seamlesske ntho e tloaelehileng ea liphaephe tse sebelisoang haholo libakeng tse sa tšoaneng. Melemo ea eona e kenyelletsa ho hanyetsa khatello e ntle haholo, ho hanyetsa mocheso, ts'ebetso e ka tšeptjoang ea ho tiisa le ho hanyetsa ho hoholo ha kutu. Ka tlase ke tla fana ka kenyelletso e qaqileng ea liphaephe tsa tšepe tse se nang seamed tse entsoeng ka mochine ho tloha likarolong tse tharo: thepa ea thepa, mekhoa ea tlhahiso le masimo a kopo.

1.Material properties

Hangata liphaephe tsa tšepe tse se nang seamless li entsoe ka tšepe ea boleng bo holimo kapa lisebelisoa tsa tšepe tsa alloy, tse nang le matla a phahameng le ho hanyetsa ho apara. Libaka tsa eona tse ka hare le tse ka ntle li boreleli 'me botenya ba lerako la phala bo lekana, bo ka finyellang litlhoko tsa thepa ea liphaephe ka linako tse fapaneng. Ho phaella moo, liphaephe tsa tšepe tse se nang moeli li na le khanyetso e ntle ea kutu 'me li ka sebelisoa nako e telele libakeng tse sa tšoaneng tse thata.

2. Mokhoa oa tlhahiso

Ts'ebetso ea ho etsa liphaephe tsa tšepe tse sa sebetseng ka mochini haholo e kenyelletsa lits'ebetso tse peli: extrusion le perforation ea tšepe. Ntlha ea pele, khetha tšepe e loketseng ho etsa liphaephe tsa tšepe tse se nang moeli 'me u li chese ka mocheso o phahameng ho nolofatsa tšepe ka ho lekaneng. Joale, tšepe ea tšepe e futhumetseng e kenngoa ka har'a perforator, 'me tlas'a matla a perforator, tšepe e phunyeletsoa' me e lelelele ho etsa phala e se nang moeli. Qetellong, thepa ea mochine le boleng ba holim'a phala li ntlafatsoa ka ho khetha, ho taka ho batang, ho phalla ha serame le mekhoa e meng.

3.Mabaka a kopo

Lipeipi tsa tšepe tse se nang seamless tse entsoeng ka mochini li sebelisoa haholo hopetroleum, khase ea tlhaho,indasteri ea lik'hemik'hale, ho futhumatsa, phepelo ea metsi le drainage le masimo a mang. E ka sebelisoa e le liphaephe tsa lipalangoang, liphaephe tse sebetsang ka tlas'a lefatše, liphaephe tsa mohaho, joalo-joalo, ka mohlala, indastering ea oli le khase, liphaephe tsa tšepe tse entsoeng ka mochine li sebelisoa e le liphaephe tsa liliba tsa oli, liphaephe tsa khase, joalo-joalo, 'me li ka mamella khatello e phahameng le litlhoko tse phahameng tsa mocheso. Lefapheng la lik'hemik'hale, liphaephe tsa tšepe tse se nang mochini li sebelisoa haholo lisebelisoa tsa lik'hemik'hale, limela tsa petrochemical, joalo-joalo. Ho phaella moo, liphaephe tsa tšepe tse se nang seamless li ka boela tsa sebelisoa matla a motlakase, kaho, tlhahiso ea mechine le masimo a mang.

Ka kakaretso, liphaephe tsa tšepe tse se nang mochini li na le thepa e ntle haholo le mefuta e mengata ea lits'ebetso. Ke hantle ka lebaka la melemo ea eona hore liphaephe tsa tšepe tse se nang moeli li sebelisoa haholo liindastering tse sa tšoaneng. Re lumela hore liphaephe tsa tšepe tse se nang mochini li tla tsoela pele ho phetha karolo ea bohlokoa ntlafatsong ea nako e tlang le ho tlisa boiketlo bo eketsehileng tlhahisong ea rona le bophelong ba rona.

Tekanyetso ea phala ea tšepe e se nang moeli bakeng sa polokelo ea oli selemo ho pota kePipe ea mohala oa API 5L

Khase ea oli ea API 5CT, peipi ea boiler, phala ea tšepe e kopantsoeng ka har'a stock,A335 P5, P9, P11, joalo-joalo Bakeng sa ba bang, ka kopo, sheba leqephe la lintlha tsa sehlahisoa sebakeng sa marang-rang.

Nako ea poso: Dec-11-2023