Pipe ea tšepe ea alloy e sebelisoa haholo setsing sa motlakase, setsing sa matla a nyutlelie, boiler ea khatello e phahameng, mocheso o phahameng oa mocheso o phahameng, reheater le likhatello tse ling tse phahameng le liphaephe le lisebelisoa tsa mocheso o phahameng. E entsoe ka tšepe ea boleng bo phahameng ba k'habone, tšepe ea sebopeho sa alloy le tšepe e sa tsitsang mocheso ka ho bilika ho chesang (extrusion, katoloso) kapa ho roala ho bata (ho taka).

Pipe ea tšepe le phala e se nang moeli li na le kamano le phapang, e ke ke ea ferekanngoa. Pipe ea khauta e hlalosoa e le phala ea tšepe ho ea ka thepa ea tlhahiso (ke hore, thepa). Joalokaha lebitso le bolela, ke tube e entsoeng ka alloy. Pipe e se nang seam e hlalosoa e le phala ea tšepe (seam le seamless) ho latela mokhoa oa tlhahiso.

Alloy pipe ke mofuta oa phala ea tšepe e se nang seam, e arotsoeng ka phala e se nang seamless le phala e phahameng ea khatello ea mocheso. Haholo-holo e fapaneng le litekanyetso tsa tlhahiso le indasteri ea li-tubes tsa alloy, li-tubes tse kopantsoeng le tse halefileng li fetola thepa ea mochine. Kopana le maemo a hlokahalang a ho sebetsa. Ts'ebetso ea eona e phahame ho feta phala e tloaelehileng ea tšepe e se nang seamless, sebopeho sa lik'hemik'hale se na le Cr e ngata, kahoo e na le khanyetso e phahameng ea mocheso, ho hanyetsa mocheso o tlase le ho hanyetsa kutu. Carbon seamless tube e tloaelehileng ha e na likarolo tsa alloy kapa e na le likaroloana tse nyane tsa alloy. Li-tubes tsa alloy li sebelisoa haholo ho petroleum, aerospace, lik'hemik'hale, matla a motlakase, boiler, sesole le liindasteri tse ling, hobane thepa ea mechine ea li-alloy tubes e fetoha ebile e bonolo ho e fetola.

Lisebelisoa tsa lipeipi tsa tšepe tse sa tsitsang li arotsoe ka: 10, 20, 35, 45, 40Mn2, 45Mn2, 27SiMn, 20Cr, 40Cr, 20CrMo, 35CrMo, 38CrMoA1, 50CrV, 30Cr8 A50M tse 'maloa.

Litekanyetso tsa ho kenya lipeipi tsa tšepe tse se nang seamless:

1, sebopeho sa phala e se nang moeli (GB/T8162-2008) e sebelisoa bakeng sa sebopeho se akaretsang le sebopeho sa mochini oa phala ea tšepe e se nang moeli.

2, phala ea tšepe e sa tsitsang bakeng sa lipalangoang tsa mokelikeli (GB/T8163-2008) e sebelisetsoa ho tsamaisa metsi, oli, khase le maro a mang a phala ea tšepe e se nang seam.

3, e tlase le e mahareng khatello ea boiler tube e se nang seamless tšepe (GB3087-2008) e sebelisetsoa ho etsa mefuta e fapaneng ea meaho ea liphaephe tse tlase le tse mahareng tse nang le khatello e phahameng ea mocheso, phala ea metsi a belang le phala ea mouoane e futhumetseng haholo le peipi ea litene ea boleng bo holimo ea tšepe ea boleng bo holimo e kentsoeng le e batang e huloang (e phuthoa) e se nang seamless.

4, khatello e phahameng ea boiler e seamless tšepe tube (GB5310-2008) e sebelisetsoa ho etsa mocheso o phahameng le ka holim'a khatello ea metsi ka holim'a metsi a futhumatsang metsi a nang le carbon steel ea boleng bo phahameng, tšepe ea alloy le tšepe e sa keneleng mocheso e sa keneleng mocheso.

5, lisebelisoa tsa manyolo tsa lik'hemik'hale bakeng sa phala ea tšepe e se nang seamless khatello e phahameng (GB6479-2000) e loketse mocheso oa ho sebetsa oa -40 ~ 400 ℃, khatello ea ho sebetsa ea 10 ~ 30Ma lisebelisoa tsa lik'hemik'hale le liphaephe tsa boleng bo phahameng ba k'habone ea sebopeho sa tšepe le phala ea tšepe ea tšepe e se nang metsi.

6, peterole e petsoha ka tšepe e se nang seamless (GB9948-2006) e loketse peteroleum refinery sebōpi, mocheso exchanger le pipeline seamless tšepe phala.

Alloy tšepe phala lisebelisoa ho ea ka botenya, litlhaloso li ka aroloa ka 12-42CrMO, T91, 30CrMo, 20G, 15CrMoV, Cr9Mo, 27SiMn, 10CrMo910, 15Mo3, 35CrMoV, 45CrMor, 2CrMor, 15CrMov, 15CrMov, 15CrMov 16Mn 12Cr1MoV, 50Cr, 15CrMo, 45CrNiMo, joalo-joalo Peipi ea tšepe ea alloy e entsoe ka tšepe ea carbon, tšepe e sa hloekang le tšepe e entsoeng ka motsoako ka theknoloji e batang ea ho roala kapa theknoloji e chesang e chesang.

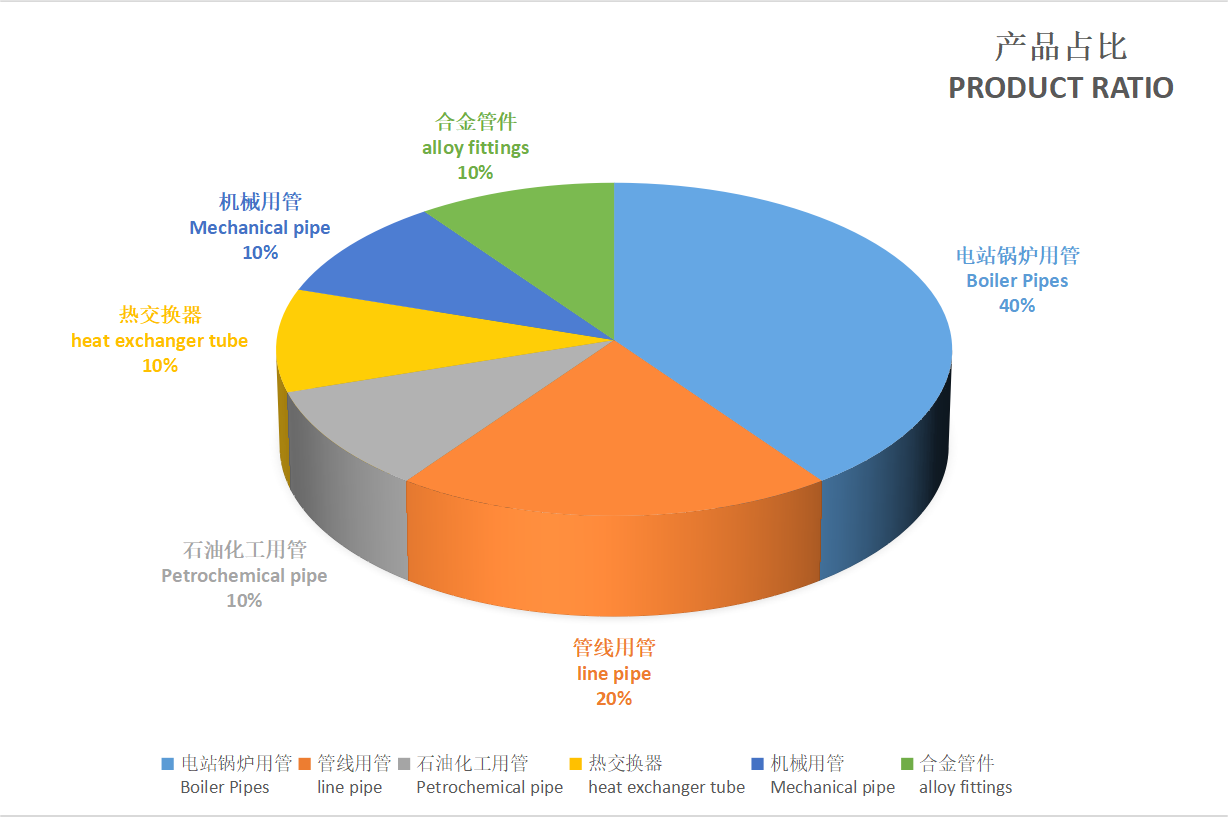

Sanon Pipe Lihlahisoa tse ka Sehloohong: Cr5Mo Alloy Tube, 15CrMo Alloy Tube, 12Cr1MoVG Alloy Tube, High Pressure Alloy Tube, 12Cr1MoV Alloy Tube, 15CrMo Alloy Tube, P11 Alloy Tube, P12 P2 Alloy Tube, Tube Alloy Tube 1 P91 Alloy Tube, High Pressure Boiler Tube, Chemical Fertilizer Special Tube, joalo-joalo Fana ka Theko ea morao-rao ea Alloy Tube le Litefiso tse phahameng tsa Alloy Tube.

lintho tse bonahalang: 20MnG, 25MnG, 16Mn-45Mn, 27SiMn, 15CrMo, 15CrMoG, 35CrMo, 42CrMo, 12Cr2MoG, 12Cr1MoV, 12Cr1MoVG, 10CrNB, 12CrNB9 10CrMoAl, 9Cr5Mo, 9Cr18Mo,SA210A1, SA210C, SA213 T11, SA213 T12, SA213 T22, SA213 T23, SA213 T91, SA213 T92, ST45.8/Ⅲ, 4, 13Cr3Mo, 4, 15 Cr. 10CrMo910, WB36, Cr5Mo, P11, P12, P22, T91, P91, 42CrMo, 35Crmo, 1Cr5Mo, 40Cr, Cr5Mo, 15CrMo 15CrMoV 25CrMo 35CrMo 35CrMo 35CrMo 35CrMo 35CrMo 35CrMo 35CrMo 35CrMo 20G Cr9Mo 15Mo3 A335P11. Lipatlisiso tsa tšepe 102, ST45.8-111, A106B Alloy Pipe.

PhethaASME SA-106/SA-106M-2015,ASTMA210(A210M)-2012,ASMESA-213/SA-213M,ASTM A335/A335M-2018,ASTM-A519-2006,ASTM A53 / A53M - 2012, joalo-joalo GbGB8162-2018 (Pipe ea Sebopeho), GB8163-2018 (Peipi ea Mokelikeli),GB3087-2008 (Pipe ea Boiler ea Khatello e Tlase le e Bohareng),GB5310-2017 (Peipi ea Boiler ea Khatello e Phahameng),Gb6479-2013 (Peipi e Khethehileng ea Fertilizer ea K'hemik'hale),GB9948-2013 (Peipi e Hlahlang Petroleum),GB/T 17396-2009(Li-Tubes tsa Tšepe tse Seamless Bakeng sa Morafo oa Mashala), jj. Ho na le HapeAPI5CT (Casing And Tubing),API 5L(Pipeline)

Nako ea poso: Aug-23-2022