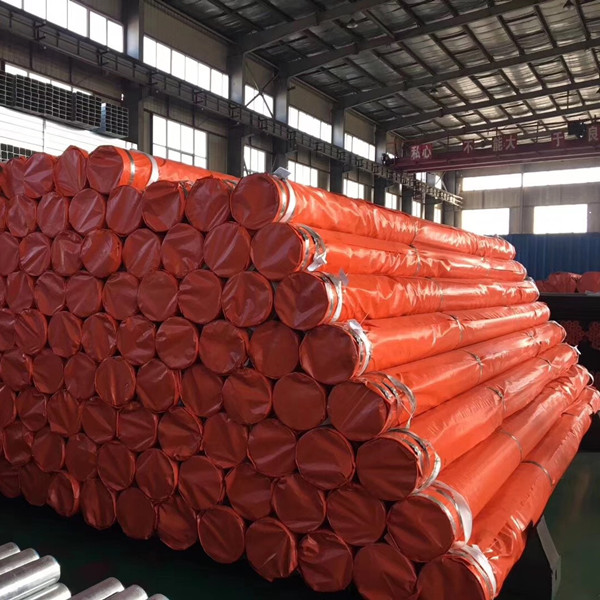

seamless boiler alloy steel pipe Khatello e tlase Khatello e mahareng

| Tloaelo:GB/T3087-2008 | Alloy Kapa Che: tšepe ea carbon e se nang moeli |

| Sehlopha sa sehlopha: 10#,20# | Kopo: Pipe ea Boiler |

| Botenya: 1 - 100 mm | Surface Treatment: Joalo ka tlhoko ea moreki |

| Bophara ba Kantle(Lepotoloho): 10 - 1000 mm | Theknoloji: Ho qojoa ka ho chesa / ho huloa ka ho bata |

| Bolelele: Bolelele bo tsitsitseng kapa bolelele bo sa reroang | Phekolo ea mocheso: Ho tloaeleha |

| Sebopeho sa Karolo: Ho potoloha | Pipe e Khethehileng: Pipe e Tenya ea Lerako |

| Sebaka sa Tšimoloho: Chaena | Tšebeliso: Kaho, Lipalangoang tsa Mokelikeli, Boiler le Mocheso oa Mocheso |

| Setifikeiti: ISO9001:2008 | Teko: ET/UT |

E sebelisoa haholo ho etsa tšepe ea boleng bo holimo ea khabone, phala e tlase ea khatello e mahareng ea khatello e tlase, peipi ea tšepe e futhumetseng ea mouoane e se nang seamless.

Mophato oa tšepe ea boleng bo holimo ea khabone: 10#,20#

| Standard | Kereiti | Sebopeho sa Lik'hemik'hale(%) | |||||||

| C | Si | Mn | P | S | Cr | Cu | Ni | ||

| GB3087 | 10 | 0.07–0.13 | 0.17–0.37 | 0.38–0,65 | ≤0.030 | ≤0.030 | 0.3–0.65 | ≤0.25 | ≤0.30 |

| 20 | 0.17–0.23 | 0.17–0.37 | 0.38–0,65 | ≤0.030 | ≤0.030 | 0.3–0.65 | ≤0.25 | ≤0.30 | |

| Standard | Pipe ea tšepe | Botenya ba lebota | Matla a tšepe | Hlahisa Matla | Elongation |

| GB3087 | (mm) | (MPa) | (MPa) | % | |

| ≥ | |||||

| 10 | / | 335-475 | 195 | 24 | |

| 20 | <15 | 410-550 | 245 | 20 | |

| ≥15 | 225 | ||||

Ho kheloha ho lumelletsoeng ha bophara ba kantle ba li-tubes tsa tšepe

| Mofuta oa tšepe ea tšepe | Ho kheloha ho lumelletsoeng | ||||||

| Chelete ea tšepe e chesang (e ntšitsoeng, e atolositsoeng). | ± 1.0% D kapa ± 0.50, nka palo e kholoanyane | ||||||

| Pepe ea tšepe e batang (e phuthoang). | ± 1.0% D kapa ± 0.30, nka palo e kholoanyane | ||||||

Phapang e lumellehang ea botenya ba lerako la li-tubes tsa tšepe tse chesang (extrusion, katoloso)

Yuniti: mm

| Mofuta oa tšepe ea tšepe | Bophara ba ka ntle ba tube ea tšepe | S / D | Ho kheloha ho lumelletsoeng | ||||||

| ho chesa (extruded) tšepe tube | ≤102 | - | ± 12.5 % S kapa ± 0.40, nka palo e kholoanyane | ||||||

| > 102 | ≤ 0.05 | ± 15% S kapa ± 0.40, nka palo e kholoanyane | |||||||

| > 0,05 ~ 0.10 | ± 12.5% S kapa ± 0.40, nka palo e kholoanyane | ||||||||

| > 0.10 | + 12,5% S | ||||||||

| - 10% S | |||||||||

| chesang eketsa tšepe tube | + 15% S | ||||||||

Ho kheloha ho lumelletsoeng ha lerako le botenya ba li-tubes tsa tšepe tse batang tse huloang (tse phuthohileng).

Yuniti: mm

| Mofuta oa tšepe ea tšepe | Botenya ba lebota | Ho kheloha ho lumelletsoeng | ||||||

| Pepe ea tšepe e batang (e phuthoang). | ≤3 | 15 - 10 % S kapa ± 0.15, nka palo e kholoanyane | ||||||

| > 3 | + 12,5% S | |||||||

| - 10% S | ||||||||

Teko e bataletseng

Li-tubes tsa tšepe tse bophara ba ka ntle ho feta 22 mm le ho fihla ho 400 mm, le botenya ba lebota bo fetang 10 mm bo lokela ho etsoa tlhahlobo ea ho batalla. Ka mor'a hore lisampole li batalatsoe

Teko ea ho koba

Li-tubes tsa tšepe tse nang le bophara bo ka ntle bo sa feteng limilimithara tse 22 li lokela ho etsoa tlhahlobo ea ho kobeha. Lekhalo le kobehang ke 90o . Radius e kobehang ke makhetlo a 6 bophara ba ka ntle ba tube ea tšepe. Ka mor'a ho koba sampuli, ha ho maphao kapa mapetsong a lumelloang ho hlaha sampuling.

Tlhahlobo ea macroscopic

Bakeng sa li-tubes tsa tšepe tse entsoeng ka ho toba ka li-billet kapa li-ingots tsa tšepe tse sa khaotseng, mofani oa thepa o lokela ho tiisa hore ha ho na matheba a masoeu, litšila, li-bubble tsa moea tse ka tlas'a holim'a metsi, maqeba a lehata kapa lesela holim'a lesela la macroscopic le nang le macroscopic acid. tube ea tšepe.

Tlhahlobo e sa senyeheng

Ho ea ka kopo ea mokha o batlang, e ntan'o buisanoa pakeng tsa mekha e fanang ka thepa le e batlang 'me e bontšitsoe tumellanong, ho lemoha phoso ea ultrasonic ho ka etsoa ka bomong bakeng sa li-tubes tsa tšepe. Bofokoli ba longitudinal bukana ea tube ea mohlala ea referense e lokela ho fihlela litlhoko tsa sehlopha sa kamohelo ea kamora tlhahlobo ea C8 e boletsoeng ho GB/T 5777-1996.