[Kopisha] Iityhubhu zentsimbi ezingenamthungo zoKuqhekezwa kwePetroleum,GB9948-2006,Sanon Pipe

Isishwankathelo

Umgangatho: GB9948-2006

IQela leBakala: 10,12CrMo,15CrMo, 07Crl9Nil0, njl

Ukutyeba: 1 - 100 mm

I-Diameter yangaphandle (Round): 10 - 1000 mm

Ubude: Ubude obuzinzileyo okanye ubude obungenamkhethe

Ubume beCandelo: Round

Indawo yemvelaphi: eTshayina

Isiqinisekiso: ISO9001:2008

Unyango loBubushushu: Ukuphelisa/ukunciphisa/ubushushu

I-Diameter yangaphandle (Round): 10 - 1000 Mm

Isicelo: iityhubhu zokutshintsha ubushushu

Unyango loMphezulu: NjengeMfuno yoMthengi

Ubuchwephesha: I-Hot Rolled

Umbhobho oKhethekileyo: Umbhobho oshinyeneyo wodonga

Ukusetyenziswa: iityhubhu zokutshintsha ubushushu

Uvavanyo:UT/MT

Isicelo

Iityhubhu zentsimbi ezingenamthungo zokuqhekeka kwepetroleum zisebenza kwiityhubhu zentsimbi ezingenamthungo kwiityhubhu zesithando somlilo, iityhubhu zokutshintshiselana ngobushushu kunye nemibhobho yoxinzelelo kwishishini lepetrochemical.

Umgangatho ophezulu we-carbon structural steel grade 20g, 20mng kunye ne-25mng.

I-alloy yezakhiwo zentsimbi: 15mog, 20mog, 12crmog

15CrMoG, 12Cr2MoG, 12CrMoVG, njl

IBanga eliPhambili

IBanga lentsimbi yolwakhiwo oluphezulu lwekhabhoni: 10#,20#

Umgangatho ophezulu we-carbon structural steel grade : 20g, 20mng kunye ne-25mng

I-alloy yezakhiwo zentsimbi: 15mog, 20mog, 12crmog, 15CrMoG, 12Cr2MoG, njl.

ICandelo leMichiza

| No | IBanga | Icandelo leMichiza % | ||||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | |||

| ≤ | ||||||||||||||

| Umgangatho ophezulu we-carbon structural steel | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | ||

| Ingxubevange yentsimbi yesakhiwo | 12CrMo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 15CrMo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | ||

| 12CrlMo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | ||

| 12CrlMoV | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0.025 | 0. 010 | ||

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | ||

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | |||

| 12Cr5MONT | ||||||||||||||

| 12Cr9MoI | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | ||

| 12Cr9MONT | ||||||||||||||

| Intsimbi ekwaziyo ukumelana nobushushu | 07Crl9Nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 | |

| 07Crl8NillNb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | ||

| 07Crl9NillTi | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00~13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0. 015 | ||

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | ||

IPropati yoomatshini

| Hayi | Ukuqina MPa | Yima kancinci MPa | Ixesha elide emva kokwaphuka A/% | Amandla okufunxa ookrebe kv2/j | Inombolo yokuqina kweBrinell | ||

| umfanekiso | umdluliseli | umfanekiso | umdluliseli | ||||

| hayi ngaphantsi kwe | hayi ngaphezulu kwe | ||||||

| 10 | 335〜475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410〜550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410〜560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440〜640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415〜560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470〜640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450~600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415〜590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MONT | 480〜640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460〜640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9MONT | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9NilO | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | >520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | >520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | >485 | 170 | 35 | 一 | - | 187 HBW | |

| Kwintsimbi enobunzima bodonga obungaphantsi kwe-5mm ityhubhu musa ukwenza umfuniselo wobulukhuni | |||||||

Imfuneko yoVavanyo

Uvavanyo lwe-hydraulic

Uvavanyo lwe-hydraulic luya kwenziwa kwimibhobho yentsimbi nganye nganye. Uxinzelelo oluphezulu lovavanyo luyi-20 MPa. Ngaphantsi koxinzelelo lovavanyo, ixesha lokuzinza aliyi kuba ngaphantsi kwe-10 s, kwaye ukuvuza kombhobho wensimbi akuvumelekanga.

Uvavanyo lokucaba

Uvavanyo lwe-flattening luya kuqhutywa kumbhobho wentsimbi kunye nobubanzi obungaphandle ngaphezu kwe-22 mm

Uvavanyo lomlilo

Umgangatho ophezulu we-carbon structural steel kunye nemibhobho yentsimbi (ekwazi ukumelana nobushushu) kunye nobubanzi obungaphandle obungekho ngaphezu kwe-76 mm kunye nobukhulu bodonga obungekho ngaphezu kwe-8 mm buya kuxhomekeka kuvavanyo olwandisiweyo. Uvavanyo lokuvutha luya kwenziwa kwiqondo lokushisa. Umyinge wangaphandle wokugqabhuka kwesampulu emva kokuba i-taper ye-core core i-60% ye-flaring iya kuhlangabezana neemfuno zetheyibhile 7. Akukho kuphazamiseka okanye ukuqhekeka kuvunyelwe kwisampuli emva kokuvutha. Ngokweemfuno zomfaki-sicelo kwaye kuphawulwe kwikhontrakthi, i-alloy structural steel ingasetyenziselwa ukwandisa uvavanyo.

Itesta engonakalisiyo

Imibhobho yensimbi iya kuba phantsi kokufumanisa impazamo ye-ultrasonic nganye ngokuhambelana namalungiselelo e-GB / T 5777-2008. Ngokweemfuno zomfaki-sicelo, ezinye iimvavanyo ezingonakalisi zingongezwa emva kokuxoxisana phakathi komthengisi kunye nomceli kwaye ziboniswe kwisivumelwano.

Uvavanyo lwe-Intergranular Corrosion

Uvavanyo lwe-Intergranular corrosion luya kuqhutywa kumbhobho wentsimbi ongenasici (ukumelana nobushushu). Indlela yokuvavanya iya kuhambelana namalungiselelo endlela yaseTshayina E kwi-GB / T 4334-2008, kwaye ukuthambekela kwe-intergranular corrosion akuvumelekanga emva kovavanyo.

Emva kothethathethwano phakathi komthengisi kunye nomenzi, kwaye kuphawulwe kwikhontrakthi, umfaki-sicelo unokubeka ezinye iindlela zovavanyo lomhlwa.

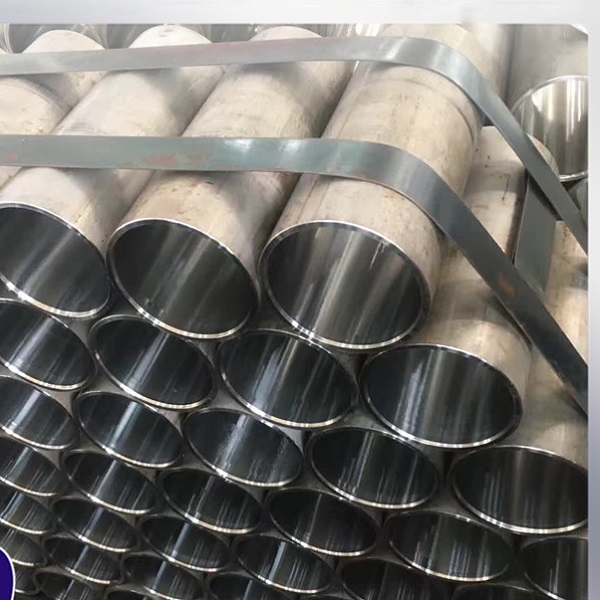

![[Kopisha] Iityhubhu zentsimbi ezingenamthungo zoKuqhekeka kwePetroleum,GB9948-2006,iSanon Pipe eFakelwe umfanekiso](http://www.sanonpipe.com/uploads/ff652257.jpg)

![[Kopisha] Iityhubhu zentsimbi ezingenamthungo zoKuqhekezwa kwePetroleum,GB9948-2006,Sanon Pipe](http://www.sanonpipe.com/uploads/ff652257-300x300.jpg)

![[Kopisha] Iityhubhu zentsimbi ezingenamthungo zoKuqhekezwa kwePetroleum,GB9948-2006,Sanon Pipe](http://www.sanonpipe.com/uploads/8f454869-300x300.jpg)

![[Kopisha] Iityhubhu zentsimbi ezingenamthungo zoKuqhekezwa kwePetroleum,GB9948-2006,Sanon Pipe](http://www.sanonpipe.com/uploads/e19d0a6e-300x300.jpg)