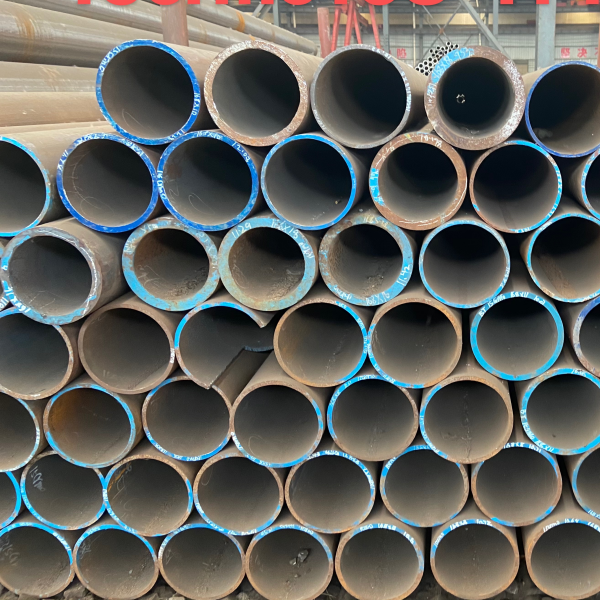

Wholesale Discount 12cr1movg Seamless Alloy Steel Pipe

Re ntse re tsepamisitse maikutlo ho ntlafatseng tsamaiso ea lintho le lenaneo la QC ho netefatsa hore re ka boloka phaello e matla ho tsoa k'hamphaning e hlolisang ka matla bakeng sa Theko ea Theolelo ea 12cr1movg Seamless Alloy Steel Pipe, Re amohela ka tieo balekane ba khoebo ba kantle le ba malapeng, 'me re tšepa ho sebetsa le bona. uena nakong e tlang e haufi!

Re ntse re tsepamisitse maikutlo ho ntlafatseng tsamaiso ea lintho le lenaneo la QC ho netefatsa hore re ka boloka phaello e ntle ho tsoa k'hamphaning e hlolisang ka matla bakeng saChina Seamless Alloy Steel Pipe le Alloy Steel Pipe, Re amohela bareki ba tsoang lefats'eng lohle ho tla buisana ka khoebo. Re fana ka lihlahisoa tsa boleng bo holimo, litheko tse ntle le litšebeletso tse ntle. Re tšepa ho theha likamano tsa khoebo le bareki ba tsoang hae le kantle ho naha, re ntse re loanela ho fumana botle bo botle hosane.

Kakaretso

| Tloaelo:GB/T5310-2017 | Alloy kapa Che: Alloy |

| Sehlopha sa Sehlopha: 20G, 20MnG, 25MnG, joalo-joalo | Kopo: Pipe ea Boiler |

| Botenya: 1 - 100 mm | Surface Treatment: Joalo ka tlhoko ea moreki |

| Bophara ba Kantle(Ho potoloha): 10 - 1200 mm | Theknoloji: Hot Rolled |

| Bolelele: Bolelele bo tsitsitseng kapa bolelele bo sa reroang (6-12m) | Phekolo ea mocheso: Ho kopanya/normalizing |

| Sebopeho sa Karolo: Ho potoloha | Pipe e Khethehileng: Pipe ea Boiler |

| Sebaka sa Tšimoloho: Chaena | Tšebeliso: Boiler le Heat Exchanger |

| Setifikeiti: ISO9001:2008 | Teko: ECT/UT/Hydrau Static |

Kopo

Haholo-holo e sebelisetsoa ho etsa tšepe ea boleng bo phahameng ea carbon, tšepe ea motsoako oa alloy le lipeipi tsa tšepe tse sa keneleng mocheso bakeng sa khatello e phahameng le ka holim'a lipeipi tsa boiler tsa mouoane.

Haholo-holo e sebelisoa bakeng sa tšebeletso ea khatello e phahameng le mocheso o phahameng oa boiler (Superheater tube, reheater tube, air guide tube, main steam tube for high and Ultra high pressure boilers). Tlas'a ketso ea mocheso o phahameng oa mocheso oa mocheso le mouoane oa metsi, tube e tla oxidize le ho senya. Ho hlokahala hore phala ea tšepe e be le nako e telele ea nako e telele, e hanyetsanang haholo le oxidation le corrosion, le botsitso bo botle ba sebopeho.

Kereiti e ka Sehloohong

Kereiti ea boleng bo phahameng ba tšepe ea sebopeho sa carbon: 20g, 20mng, 25mng

Kereiti ea tšepe ea sebopeho sa motsoako: 15mog, 20mog, 12crmog, 15crmog, 12cr2mog, 12crmovg, 12cr3movsitib, joalo-joalo.

Mophato oa tšepe e sa keneleng mocheso: 1cr18ni9 1cr18ni11nb

Karolo ea Lik'hemik'hale

| Kereiti | Boleng Sehlopha | Thepa ea Lik'hemik'hale | ||||||||||||||

| C | Si | Mn | P | S | Nb | V | Ti | Cr | Ni | Cu | Nd | Mo | B | Als” | ||

| Eseng ho feta | min | |||||||||||||||

| Q345 | A | 0.20 | 0.50 | 1.70 | 0.035 | 0.035 | 0.30 | 0.50 | 0.20 | 0.012 | 0.10 | - | - | |||

| B | 0.035 | 0.035 | ||||||||||||||

| C | 0.030 | 0.030 | 0.07 | 0.15 | 0.20 | 0.015 | ||||||||||

| D | 0.18 | 0.030 | 0.025 | |||||||||||||

| E | 0.025 | 0.020 | ||||||||||||||

| Q390 | A | 0.20 | 0.50 | 1.70 | 0.035 | 0.035 | 0.07 | 0.20 | 0.20 | 0.3. | 0.50 | 0.20 | 0.015 | 0.10 | - | - |

| B | 0.035 | 0.035 | ||||||||||||||

| C | 0.030 | 0.030 | 0,015 | |||||||||||||

| D | 0.030 | 0.025 | ||||||||||||||

| E | 0.025 | 0.020 | ||||||||||||||

| Q42O | A | 0.20 | 0.50 | 1.70 | 0.035 | 0.035 | 0.07 | 0.2. | 0.20 | 0.30 | 0.80 | 0.20 | 0.015 | 0.20 | - | - |

| B | 0.035 | 0.035 | ||||||||||||||

| C | 0.030 | 0.030 | 0.015 | |||||||||||||

| D | 0.030 | 0.025 | ||||||||||||||

| E | 0.025 | 0.020 | ||||||||||||||

| Q46O | C | 0.20 | 0.60 | 1.80 | 0.030 | 0.030 | 0.11 | 0.20 | 0.20 | 0.30 | 0.80 | 0.20 | 0.015 | 0.20 | 0.005 | 0.015 |

| D | 0.030 | 0.025 | ||||||||||||||

| E | 0.025 | 0.020 | ||||||||||||||

| Q500 | C | 0.18 | 0.60 | 1.80 | 0.025 | 0.020 | 0.11 | 0.20 | 0.20 | 0.60 | 0.80 | 0.20 | 0.015 | 0.20 | 0.005 | 0.015 |

| D | 0.025 | 0.015 | ||||||||||||||

| E | 0.020 | 0.010 | ||||||||||||||

| Q550 | C | 0.18 | 0.60 | 2.00 | 0.025 | 0,020 | 0.11 | 0.20 | 0.20 | 0.80 | 0.80 | 0.20 | 0.015 | 0.30 | 0.005 | 0.015 |

| D | 0.025 | 0,015 | ||||||||||||||

| E | 0.020 | 0.010 | ||||||||||||||

| Q62O | C | 0.18 | 0.60 | 2.00 | 0.025 | 0.020 | 0.11 | 0.20 | 0.20 | 1.00 | 0.80 | 0.20 | 0.015 | 0.30 | 0.005 | 0.015 |

| D | 0.025 | 0.015 | ||||||||||||||

| E | 0.020 | 0.010 | ||||||||||||||

| Ntle le limaraka tsa Q345A le Q345B, tšepe e lokela ho ba le bonyane karolo e le 'ngoe ea lijo-thollo tse hloekisitsoeng Al, Nb, V, le Ti. Ho ea ka litlhoko, mofani oa thepa a ka eketsa karolo e le 'ngoe kapa tse ngata tsa lijo-thollo tse hloekisitsoeng, boleng bo phahameng ka ho fetisisa E lokela ho finyella litlhoko tse tafoleng. Ha li kopantsoe, Nb + V + Ti <0.22% °Bakeng sa Q345, Q390, Q420 le Q46O limaraka, Mo + Cr <0.30% oHa sehlopha ka seng sa Cr le Ni se sebelisoa e le karolo e setseng, litaba tsa Cr le Ni ha lia lokela ho e be ho feta 0.30%; ha e hloka ho eketswa, dikahare tsa yona di lokela ho fihlella ditlhoko tse tafoleng kapa ho laolwe ke mofani wa thepa le moreki ka therisano.J Haeba mofani wa thepa a ka netefatsa hore dikahare tsa naetrojene di fihlella ditlhoko tse leng tafoleng, tlhahlobo ya dikahare tsa nitrogen ha e etsoe. Haeba Al, Nb, V, Ti le lisebelisoa tse ling tsa alloy tse nang le naetrojene fixation li kenngoa ka tšepe, litaba tsa naetrojene ha li na moeli. Likahare tsa ho lokisa naetrojene li lokela ho boleloa setifikeiting sa boleng. 'Ha u sebelisa aluminium kaofela, kakaretso ea aluminium AIt ^ 0.020% B | ||||||||||||||||

Thepa ea Mechini

| No | Kereiti | Thepa ea Mechini | ||||

|

|

| Tensile | Khefutsa | Eketsa | Tšusumetso (J) | Handness |

| 1 | 20G | 410- | ≥ | 24/22% | 40/27 | - |

| 2 | 20MnG | 415- | ≥ | 22/20% | 40/27 | - |

| 3 | 25MnG | 485- | ≥ | 20/18% | 40/27 | - |

| 4 | 15MoG | 450- | ≥ | 22/20% | 40/27 | - |

| 6 | 12CrMoG | 410- | ≥ | 21/19% | 40/27 | - |

| 7 | 15CrMoG | 440- | ≥ | 21/19% | 40/27 | - |

| 8 | 12Cr2MoG | 450- | ≥ | 22/20% | 40/27 | - |

| 9 | 12Cr1MoVG | 470- | ≥ | 21/19% | 40/27 | - |

| 10 | 12Cr2MoWVTiB | 540- | ≥ | 18/-% | 40/- | - |

| 11 | 10Cr9Mo1VNbN | ≥ | ≥ | 20/16% | 40/27 | ≤ |

| 12 | 10Cr9MoW2VNbBN | ≥ | ≥ | 20/16% | 40/27 | ≤ |

Mamello

Botenya ba Lebota le Bophara ba Kantle:

Haeba ho se na litlhoko tse khethehileng, phaephe e tla tsamaisoa e le bophara bo tloaelehileng ba kantle le botenya ba lebota bo tloaelehileng. Joalo ka leqephe la ho latela

| Tlhaloso ea lihlopha | Mokhoa oa ho etsa | Boholo ba phala | Mamello | |||

| Sekolo se tloaelehileng | Kereiti e phahameng | |||||

| WH | Peipi e kentsoeng e chesang (extrude) | Norminal outer Diameter (D) | <57 | Setšoantšo sa 0.40 | ±0,30 | |

| 57 〜325 | SW35 | ±0.75%D | ±0.5%D | |||

| S>35 | ±1%D | ±0.75%D | ||||

| >325 le 6. | + 1%D kapa + 5.Nka e nyenyane 一2 | |||||

| > 600 | + 1%D kapa + 7,Nka e nyenyane 一2 | |||||

| Tloaelehileng Lebota Botenya (S) | <4.0 | ±|・丨) | ±0.35 | |||

| >4.0-20 | + 12,5%S | ±10%S | ||||

| >20 | DV219 | ±10%S | ±7.5%S | |||

| 心219 | + 12,5%S -10%S | 土10%S | ||||

| WH | Pipe ea ho atolosa mocheso | Norminal outer Diameter (D) | kaofela | ±1%D | ± 0.75%. |

| Tloaelehileng Lebota Botenya (S) | kaofela | + 20%S -10%S | + 15%S -io%s | ||

| WC | E batang (e phuthoa) Ppipe | Norminal outer Diameter (D) | <25.4 | ±L1j | - |

| >25.4 〜4() | ±0.20 | ||||

| > 40 〜50 | |:0.25 | - | |||

| > 50 〜60 | ±0.30 | ||||

| > 60 | ±0.5%D | ||||

| Tloaelehileng Lebota Botenya (S) | <3.0 | ±0.3 | ±0.2 | ||

| >3.0 | S | ±7.5%S |

Bolelele:

Bolelele bo tloaelehileng ba lipeipi tsa tšepe ke 4 000 mm ~ 12 000 mm. Ka mor'a ho buisana pakeng tsa mofani oa thepa le moreki, 'me u tlatse konteraka, e ka tsamaisoa liphaephe tsa tšepe tse nang le bolelele bo fetang 12 000 mm kapa bokhutšoane ho feta I 000 mm empa e se khutšoanyane ho feta 3 000 mm; bolelele bo bokhuts'oanyane Palo ea lipeipi tsa tšepe tse ka tlase ho 4,000 mm empa e seng ka tlase ho 3,000 mm ha e na ho feta 5% ea palo eohle ea lipeipi tsa tšepe tse fanoeng.

Boima ba thomello:

Ha phala ea tšepe e fanoa ho ea ka bophara bo ka ntle ba lebitso le botenya ba lebota la lebitso kapa bophara bo ka hare bo ka hare le botenya ba lerako, phala ea tšepe e fanoa ho latela boima ba 'nete. E ka boela ea fanoa ho ea ka boima ba theory.

Ha phala ea tšepe e fanoa ho ea ka bophara bo ka ntle ba lebitso le bonyane botenya ba lerako, phala ea tšepe e fanoa ho latela boima ba 'nete; mekha ea phepelo le tlhokahalo e buisana. 'Me e bontšitsoe konteraka. Pipe ea tšepe e ka boela ea fanoa ho ea ka boima ba theory.

Boima ba 'mele:

Ho ea ka litlhoko tsa moreki, ka mor'a ho buisana pakeng tsa mofani oa thepa le moreki, 'me tumellanong, ho kheloha pakeng tsa boima ba' mele le boima ba khopolo ea pipe ea tšepe ea pelehi ho tla finyella litlhoko tse latelang:

a) Pipe ea tšepe e le 'ngoe: ± 10%;

b) Sehlopha se seng le se seng sa liphaephe tsa tšepe tse nang le bonyane ba boholo ba 10 t: ± 7.5%.

Tlhokahalo ea Teko

Teko ea Hydraustatic:

Pipe ea tšepe e lokela ho lekoa ka hydraulically ka bonngoe. Khatello e phahameng ea teko ke 20 MPa. Tlas'a khatello ea teko, nako ea botsitso ha ea lokela ho ba tlase ho 10 s, 'me pipe ea tšepe ha ea lokela ho tsoa.

Kamora hore mosebelisi a lumele, tlhahlobo ea hydraulic e ka nkeloa sebaka ke tlhahlobo ea eddy ea hajoale kapa tlhahlobo ea ho lutla ha magnetic flux.

Teko e sa Senyeheng:

Liphaephe tse hlokang tlhahlobo e eketsehileng li lokela ho hlahlojoa ka ultrasonically ka bonngoe. Ka mor'a hore puisano e hloke tumello ea mokga mme e hlalositsoe konteraka, liteko tse ling tse sa senyeheng li ka eketsoa.

Teko ea ho batalatsa:

Li-tubes tse nang le bophara ba ka ntle ho feta 22 mm li tla etsoa teko ea ho batalla. Ha ho na delamination e bonahalang, matheba a masoeu, kapa litšila tse lokelang ho etsahala nakong ea teko eohle.

Flaring Test:

Ho ea ka litlhoko tsa moreki le tse boletsoeng ka konteraka, phala ea tšepe e nang le bophara bo ka ntle ≤76mm le botenya ba lerako ≤8mm e ka etsoa tlhahlobo ea mollo . Teko e ne e etsoa ka mocheso oa kamore ka taper ea 60 °. Kamora ho phatloha, sekhahla sa ho phatloha ha bophara ba ka ntle se lokela ho fihlela litlhoko tsa tafole e latelang, 'me lisebelisoa tsa tlhahlobo ha lia lokela ho bonts'a mapheo kapa mapheo.

| Mofuta oa tšepe

| Sekhahla sa ho phatloha ka ntle sa phala ea tšepe /% | ||

| Diameter ka hare / Kantle Diameter | |||

| <0.6 | >0.6 〜0.8 | >0.8 | |

| Litšepe tsa boleng bo phahameng ba carbon structural | 10 | 12 | 17 |

| Mohaho alloy tšepe | 8 | 10 | 15 |

| • Bophara bo ka hare bo baloa bakeng sa sampuli. | |||

Lintlha tsa Sehlahisoa

Li-tubes tsa tšepe tse se nang seam bakeng sa li-boilers tsa khatello e phahameng

GB/T5310-2017

ASME SA-106/SA-106M-2015

ASTMA210(A210M)-2012

ASME SA-213/SA-213M

ASTM A335/A335M-2018

Re ntse re tsepamisitse maikutlo ho ntlafatseng tsamaiso ea lintho le lenaneo la QC ho netefatsa hore re ka boloka phaello e matla ho tsoa k'hamphaning e hlolisang ka matla bakeng sa Theko ea Theolelo ea 12cr1movg Seamless Alloy Steel Pipe, Re amohela ka tieo balekane ba khoebo ba kantle le ba malapeng, 'me re tšepa ho sebetsa le bona. uena nakong e tlang e haufi!

Theolelo ea KakaretsoChina Seamless Alloy Steel Pipe le Alloy Steel Pipe, Re amohela bareki ba tsoang lefats'eng lohle ho tla buisana ka khoebo. Re fana ka lihlahisoa tsa boleng bo holimo, litheko tse ntle le litšebeletso tse ntle. Re tšepa ho theha likamano tsa khoebo le bareki ba tsoang hae le kantle ho naha, re ntse re loanela ho fumana botle bo botle hosane.